What is Global Oil Free Air Compressors Market?

The Global Oil Free Air Compressors Market is a dynamic and essential segment of the broader air compressor industry. These compressors are designed to provide clean, oil-free air, which is crucial for applications where air purity is paramount. Unlike traditional air compressors that use oil for lubrication, oil-free compressors employ alternative methods to ensure that the air remains uncontaminated. This feature makes them highly desirable in industries such as food and beverage, pharmaceuticals, and electronics, where even the slightest contamination can lead to significant issues. The market for oil-free air compressors is driven by the increasing demand for high-quality air in various industrial applications, coupled with stringent regulations regarding air purity. As industries continue to prioritize sustainability and efficiency, the adoption of oil-free air compressors is expected to rise. These compressors not only help in maintaining product quality but also contribute to reducing environmental impact by eliminating the need for oil disposal. The market is characterized by continuous technological advancements aimed at improving the efficiency and reliability of these compressors, making them an integral part of modern industrial operations.

Below 50 HP, 50-100 HP, Above 100HP in the Global Oil Free Air Compressors Market:

In the Global Oil Free Air Compressors Market, the classification based on horsepower (HP) is crucial for understanding the diverse applications and capabilities of these machines. Compressors with Below 50 HP are typically used in smaller operations or applications where the demand for compressed air is not exceedingly high. These compressors are often found in small workshops, laboratories, and other settings where space and energy efficiency are important. They are valued for their compact size, ease of maintenance, and ability to deliver clean air without the risk of oil contamination. Moving up the scale, compressors in the 50-100 HP range are more robust and are used in medium-sized industrial applications. These compressors strike a balance between power and efficiency, making them suitable for a wide range of industries, including automotive, textiles, and packaging. They are designed to handle more demanding tasks while still ensuring that the air remains free of oil. The versatility of this range makes it a popular choice for businesses looking to upgrade their air systems without a significant increase in operational costs. Above 100 HP compressors represent the heavy-duty end of the spectrum. These machines are engineered for large-scale industrial applications where the demand for compressed air is substantial. Industries such as oil and gas, large-scale manufacturing, and chemical processing rely on these powerful compressors to maintain continuous operations. The high horsepower allows these compressors to deliver large volumes of air efficiently, supporting complex and energy-intensive processes. Despite their size and power, these compressors maintain the critical advantage of providing oil-free air, which is essential for maintaining product integrity and meeting regulatory standards. The choice of compressor based on horsepower is influenced by several factors, including the specific requirements of the application, the scale of operations, and the desired balance between initial investment and long-term operational efficiency. As industries evolve and the demand for clean air increases, the market for oil-free air compressors across all horsepower categories is expected to grow, driven by technological advancements and a focus on sustainability.

Food & Beverage, Electronics, Pharmaceuticals, Oil & Gas, Others in the Global Oil Free Air Compressors Market:

The usage of Global Oil Free Air Compressors Market spans several critical industries, each with unique requirements for air purity and efficiency. In the Food & Beverage sector, oil-free air compressors are indispensable. They ensure that the air used in processing, packaging, and storage is free from contaminants, which is crucial for maintaining product quality and safety. Any oil contamination could lead to spoilage or health risks, making oil-free compressors the preferred choice for this industry. In the Electronics industry, the need for clean air is equally important. Oil-free compressors are used in the manufacturing of sensitive electronic components where even the smallest particle of oil can cause defects or failures. The precision required in electronics manufacturing makes oil-free air compressors an essential tool for ensuring product reliability and performance. In the Pharmaceuticals sector, the stakes are even higher. The production of medicines and medical devices requires an environment free from any contamination to ensure the safety and efficacy of the products. Oil-free air compressors provide the necessary clean air for various processes, from mixing ingredients to packaging finished products. The Oil & Gas industry also benefits from oil-free air compressors, particularly in applications where the presence of oil could pose a safety risk or compromise the quality of the end product. These compressors are used in various stages of exploration, extraction, and processing, providing reliable and clean air for critical operations. Beyond these industries, oil-free air compressors find applications in numerous other sectors, including textiles, automotive, and healthcare, where the demand for clean, oil-free air is a common requirement. The versatility and reliability of oil-free air compressors make them a valuable asset across diverse industrial landscapes, supporting operations that prioritize quality, safety, and environmental responsibility.

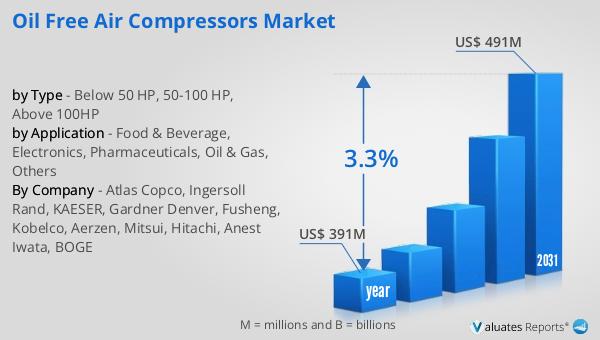

Global Oil Free Air Compressors Market Outlook:

The outlook for the Global Oil Free Air Compressors Market indicates a steady growth trajectory. In 2024, the market was valued at approximately US$ 391 million. By 2031, it is anticipated to expand to a revised size of US$ 491 million, reflecting a compound annual growth rate (CAGR) of 3.3% over the forecast period. This growth is driven by the increasing demand for clean and efficient air solutions across various industries. As businesses continue to prioritize sustainability and operational efficiency, the adoption of oil-free air compressors is expected to rise. These compressors offer significant advantages, including reduced maintenance costs and the elimination of oil disposal issues, which contribute to their growing popularity. The market's expansion is also supported by technological advancements that enhance the performance and reliability of oil-free compressors, making them an attractive option for industries seeking to improve their air systems. As the market evolves, manufacturers are likely to focus on developing innovative solutions that meet the diverse needs of their customers, further driving the growth of the Global Oil Free Air Compressors Market.

| Report Metric | Details |

| Report Name | Oil Free Air Compressors Market |

| Accounted market size in year | US$ 391 million |

| Forecasted market size in 2031 | US$ 491 million |

| CAGR | 3.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Atlas Copco, Ingersoll Rand, KAESER, Gardner Denver, Fusheng, Kobelco, Aerzen, Mitsui, Hitachi, Anest Iwata, BOGE |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |