What is Global Oil Condition Monitoring Services Market?

The Global Oil Condition Monitoring Services Market is a specialized sector that focuses on analyzing and assessing the condition of oil used in various machinery and equipment. This market plays a crucial role in maintaining the efficiency and longevity of engines, turbines, hydraulic systems, and compressors by providing insights into the oil's health. By monitoring oil conditions, businesses can prevent equipment failures, reduce maintenance costs, and enhance operational efficiency. The services offered in this market include testing for contaminants, wear particles, and chemical composition, which help in identifying potential issues before they lead to significant problems. As industries continue to rely heavily on machinery, the demand for oil condition monitoring services is expected to grow, driven by the need for cost-effective maintenance solutions and the increasing complexity of modern equipment. This market is essential for industries such as automotive, aerospace, manufacturing, and energy, where machinery downtime can lead to substantial financial losses. By ensuring that oil remains in optimal condition, these services contribute to the overall reliability and performance of industrial operations, making them an indispensable part of modern maintenance strategies.

Lubricant and Oil Testing, Grease Testing, Cylinder Liner Monitoring, Ferrography Testing, Tribology Testing in the Global Oil Condition Monitoring Services Market:

Lubricant and oil testing is a fundamental aspect of the Global Oil Condition Monitoring Services Market. This process involves analyzing the physical and chemical properties of lubricants and oils used in machinery to ensure they are functioning correctly. By testing for viscosity, acidity, and contamination levels, companies can determine the oil's ability to protect and lubricate machinery components. This testing helps in identifying issues such as oil degradation, contamination, and wear, which can lead to equipment failure if not addressed promptly. Grease testing, on the other hand, focuses on the semi-solid lubricants used in machinery. It involves assessing the grease's consistency, stability, and ability to withstand pressure and temperature variations. This testing is crucial for ensuring that the grease can effectively reduce friction and wear in moving parts, thereby extending the life of the equipment. Cylinder liner monitoring is another critical service in this market, particularly for engines. It involves examining the condition of cylinder liners to detect wear and tear, which can affect engine performance. By monitoring the liners, companies can prevent costly engine repairs and maintain optimal performance. Ferrography testing is a specialized technique used to analyze wear particles in oil. By examining the size, shape, and composition of these particles, companies can gain insights into the wear mechanisms affecting their machinery. This information is invaluable for predicting potential failures and planning maintenance activities. Tribology testing, which studies the interaction of surfaces in relative motion, is also a key component of oil condition monitoring. It involves analyzing friction, lubrication, and wear to optimize the performance and longevity of machinery. By understanding these interactions, companies can make informed decisions about lubricant selection and maintenance practices, ultimately improving equipment reliability and efficiency. Together, these testing services provide a comprehensive approach to oil condition monitoring, enabling businesses to maintain their machinery in peak condition and avoid costly downtime.

Engines, Turbines, Hydraulic Systems, Compressors, Others in the Global Oil Condition Monitoring Services Market:

The usage of Global Oil Condition Monitoring Services Market extends across various critical areas, including engines, turbines, hydraulic systems, compressors, and others. In engines, oil condition monitoring is vital for ensuring optimal performance and longevity. By regularly analyzing the oil used in engines, companies can detect issues such as contamination, wear, and degradation, which can lead to engine failure if not addressed. This proactive approach allows for timely maintenance and repairs, reducing the risk of costly breakdowns and extending the engine's lifespan. In turbines, oil condition monitoring is essential for maintaining efficiency and reliability. Turbines operate under high pressure and temperature conditions, making them susceptible to wear and tear. By monitoring the oil's condition, companies can identify potential issues early and take corrective actions to prevent turbine failures. This not only enhances the turbine's performance but also reduces maintenance costs and downtime. Hydraulic systems also benefit significantly from oil condition monitoring. These systems rely on hydraulic fluid to transmit power and lubricate components. By analyzing the oil's condition, companies can detect contamination, wear, and other issues that can affect the system's performance. This ensures that the hydraulic system operates smoothly and efficiently, reducing the risk of failures and extending its lifespan. Compressors, which are used in various industrial applications, also require regular oil condition monitoring. By analyzing the oil used in compressors, companies can detect issues such as contamination and wear, which can lead to compressor failure if not addressed. This proactive approach helps in maintaining the compressor's efficiency and reliability, reducing maintenance costs and downtime. Other areas where oil condition monitoring is used include gearboxes, bearings, and other machinery components. By ensuring that the oil used in these components remains in optimal condition, companies can enhance their performance and longevity, ultimately improving overall operational efficiency.

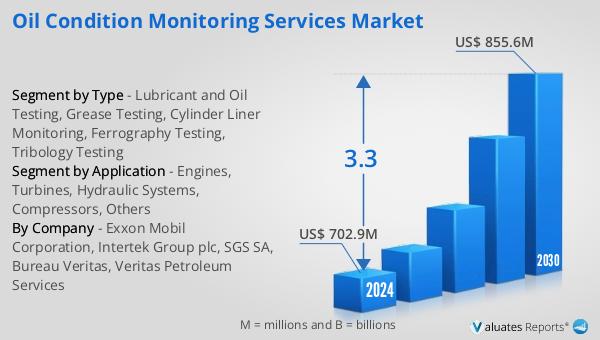

Global Oil Condition Monitoring Services Market Outlook:

The outlook for the Global Oil Condition Monitoring Services Market indicates a steady growth trajectory. The market is anticipated to expand from $702.9 million in 2024 to $855.6 million by 2030, reflecting a compound annual growth rate (CAGR) of 3.3% over the forecast period. This growth is driven by the increasing demand for efficient maintenance solutions and the rising complexity of modern machinery. The market is dominated by the top five manufacturers, who collectively hold approximately 70% of the market share. This concentration of market power highlights the competitive nature of the industry and the importance of innovation and quality in maintaining a leading position. Europe emerges as the largest market, accounting for about 40% of the global share, followed by North America with around 30%. This regional distribution underscores the significance of oil condition monitoring services in these areas, where industrial activities are prominent and machinery reliability is crucial. As industries continue to prioritize cost-effective maintenance strategies, the demand for oil condition monitoring services is expected to grow, reinforcing their role as a vital component of modern industrial operations.

| Report Metric | Details |

| Report Name | Oil Condition Monitoring Services Market |

| Accounted market size in 2024 | US$ 702.9 million |

| Forecasted market size in 2030 | US$ 855.6 million |

| CAGR | 3.3 |

| Base Year | 2024 |

| Forecasted years | 2025 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Exxon Mobil Corporation, Intertek Group plc, SGS SA, Bureau Veritas, Veritas Petroleum Services |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |