What is Global Multi-Spindle Drilling Machines Market?

The Global Multi-Spindle Drilling Machines Market refers to the worldwide industry focused on the production, distribution, and utilization of multi-spindle drilling machines. These machines are specialized equipment used in various manufacturing processes to drill multiple holes simultaneously, significantly enhancing productivity and efficiency. Multi-spindle drilling machines are essential in industries where precision and speed are crucial, such as automotive, aerospace, and electronics. The market encompasses a wide range of machine types, including vertical and horizontal configurations, each designed to meet specific operational needs. The growth of this market is driven by the increasing demand for high-speed production and the need for cost-effective manufacturing solutions. As industries continue to evolve and seek ways to optimize their operations, the adoption of multi-spindle drilling machines is expected to rise, contributing to the market's expansion. The market is characterized by technological advancements, with manufacturers continuously innovating to offer machines with enhanced capabilities, such as improved accuracy, reduced setup times, and greater flexibility. Overall, the Global Multi-Spindle Drilling Machines Market plays a vital role in modern manufacturing, providing essential tools that help industries meet the demands of a competitive global economy.

Vertical Multispindle Drilling Machines, Horizontal Multispindle Drilling Machines in the Global Multi-Spindle Drilling Machines Market:

Vertical and horizontal multi-spindle drilling machines are two primary types of equipment within the Global Multi-Spindle Drilling Machines Market, each offering unique advantages and applications. Vertical multi-spindle drilling machines are designed with spindles arranged vertically, making them ideal for operations that require drilling from above. These machines are particularly useful in applications where the workpiece is flat or needs to be drilled from the top, such as in the production of automotive components, electronic circuit boards, and metal plates. The vertical configuration allows for easy access to the workpiece and facilitates the drilling of multiple holes with high precision and speed. Additionally, vertical multi-spindle drilling machines are often equipped with advanced features such as automatic tool changers and CNC controls, enabling them to perform complex drilling tasks with minimal human intervention. On the other hand, horizontal multi-spindle drilling machines have spindles arranged horizontally, making them suitable for drilling operations that require access from the side. These machines are commonly used in industries where the workpiece is cylindrical or requires drilling along its length, such as in the manufacturing of pipes, shafts, and other elongated components. The horizontal configuration allows for efficient drilling of multiple holes along the length of the workpiece, reducing production time and increasing throughput. Horizontal multi-spindle drilling machines are often equipped with features such as adjustable spindle spacing and programmable controls, allowing for greater flexibility and customization in drilling operations. Both vertical and horizontal multi-spindle drilling machines are integral to the Global Multi-Spindle Drilling Machines Market, offering manufacturers the ability to choose the most suitable equipment for their specific needs. The choice between vertical and horizontal configurations depends on factors such as the shape and size of the workpiece, the required drilling pattern, and the desired level of automation. As industries continue to seek ways to improve efficiency and reduce costs, the demand for both types of multi-spindle drilling machines is expected to grow, driving innovation and development within the market. Manufacturers are continually exploring new technologies and materials to enhance the performance and capabilities of these machines, ensuring they remain a vital component of modern manufacturing processes. Overall, vertical and horizontal multi-spindle drilling machines play a crucial role in the Global Multi-Spindle Drilling Machines Market, providing essential tools that enable industries to meet the demands of a rapidly changing global economy.

Automotive, Shipbuilding Industry, Equipment Manufacturing, Other in the Global Multi-Spindle Drilling Machines Market:

The Global Multi-Spindle Drilling Machines Market finds extensive usage across various industries, including automotive, shipbuilding, equipment manufacturing, and others, each benefiting from the efficiency and precision these machines offer. In the automotive industry, multi-spindle drilling machines are indispensable for the mass production of vehicle components. They are used to drill multiple holes in engine blocks, transmission cases, and other critical parts, ensuring high precision and consistency. The ability to drill multiple holes simultaneously significantly reduces production time and costs, allowing automotive manufacturers to meet the high demand for vehicles while maintaining quality standards. In the shipbuilding industry, multi-spindle drilling machines are used to drill holes in large metal sheets and plates that form the hull and other structural components of ships. The machines' ability to handle large workpieces and perform complex drilling operations with high accuracy is crucial in ensuring the structural integrity and safety of ships. Equipment manufacturing also relies heavily on multi-spindle drilling machines for the production of machinery and equipment components. These machines are used to drill holes in metal, plastic, and composite materials, enabling the efficient assembly of various equipment types, from industrial machinery to consumer electronics. The versatility and precision of multi-spindle drilling machines make them ideal for producing components with complex geometries and tight tolerances. Beyond these industries, multi-spindle drilling machines are also used in sectors such as aerospace, electronics, and construction, where precision and efficiency are paramount. In aerospace, for example, these machines are used to drill holes in aircraft components, ensuring they meet stringent safety and performance standards. In electronics, multi-spindle drilling machines are used to produce circuit boards and other components that require precise hole patterns. The construction industry also benefits from the use of multi-spindle drilling machines in the production of building materials and components. Overall, the Global Multi-Spindle Drilling Machines Market plays a vital role in supporting the manufacturing needs of various industries, providing essential tools that enhance productivity, reduce costs, and improve product quality. As industries continue to evolve and face new challenges, the demand for multi-spindle drilling machines is expected to grow, driving innovation and development within the market.

Global Multi-Spindle Drilling Machines Market Outlook:

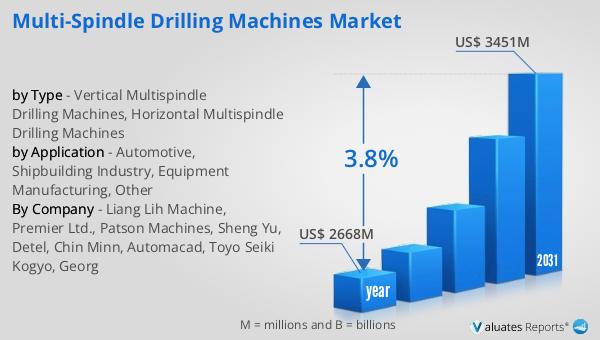

The global market for multi-spindle drilling machines was valued at $2,668 million in 2024 and is anticipated to expand to a revised size of $3,451 million by 2031, reflecting a compound annual growth rate (CAGR) of 3.8% over the forecast period. This growth trajectory underscores the increasing demand for efficient and high-speed drilling solutions across various industries. The market's expansion is driven by the need for cost-effective manufacturing processes and the continuous advancements in drilling technology. As industries strive to enhance productivity and reduce operational costs, the adoption of multi-spindle drilling machines is expected to rise, contributing to the market's growth. The projected increase in market size highlights the importance of these machines in modern manufacturing, where precision and speed are critical. Manufacturers are investing in research and development to introduce innovative features and capabilities, ensuring that multi-spindle drilling machines remain at the forefront of industrial automation. The market's growth also reflects the broader trend towards automation and digitalization in manufacturing, as companies seek to optimize their operations and remain competitive in a rapidly changing global economy. Overall, the global multi-spindle drilling machines market is poised for significant growth, driven by the increasing demand for efficient and cost-effective drilling solutions.

| Report Metric | Details |

| Report Name | Multi-Spindle Drilling Machines Market |

| Accounted market size in year | US$ 2668 million |

| Forecasted market size in 2031 | US$ 3451 million |

| CAGR | 3.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Liang Lih Machine, Premier Ltd., Patson Machines, Sheng Yu, Detel, Chin Minn, Automacad, Toyo Seiki Kogyo, Georg |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |