What is Global Mercaptoethanol Market?

The global mercaptoethanol market is a specialized segment within the broader chemical industry, focusing on the production and distribution of mercaptoethanol, a chemical compound known for its distinctive sulfur-like odor. This compound is primarily used as a reducing agent in various industrial applications due to its ability to break disulfide bonds. Mercaptoethanol is a colorless liquid that is highly soluble in water, making it versatile for different uses. It is often utilized in the manufacturing of pharmaceuticals, agrochemicals, and as a stabilizer in the production of polymers and rubber. The demand for mercaptoethanol is driven by its critical role in these industries, where it helps in maintaining the stability and functionality of products. Additionally, its application in water treatment processes highlights its importance in environmental management. The market for mercaptoethanol is influenced by factors such as technological advancements, regulatory frameworks, and the overall growth of end-use industries. As industries continue to expand and innovate, the demand for mercaptoethanol is expected to rise, reflecting its essential role in modern industrial processes. The market dynamics are shaped by the balance between supply and demand, production capacities, and the development of alternative compounds that could potentially replace mercaptoethanol in certain applications.

Above 99%, Below 99% in the Global Mercaptoethanol Market:

In the global mercaptoethanol market, the purity of the product is a significant factor that influences its application and value. Mercaptoethanol is typically available in two main purity grades: above 99% and below 99%. The above 99% purity grade is often preferred for applications that require high precision and minimal impurities, such as in pharmaceuticals and biotechnology. This high-purity mercaptoethanol is crucial in these fields because it ensures the integrity and effectiveness of the processes and products. For instance, in the pharmaceutical industry, high-purity mercaptoethanol is used in the synthesis of active pharmaceutical ingredients (APIs) and in the formulation of drugs where any impurities could affect the safety and efficacy of the final product. Similarly, in biotechnology, it is used in the preparation of buffers and reagents where purity is paramount to avoid any interference with biological reactions. On the other hand, mercaptoethanol with a purity below 99% is generally used in applications where the presence of minor impurities does not significantly impact the performance of the product. This includes certain industrial applications such as in the production of polymers and rubber, where mercaptoethanol acts as a stabilizer or a processing aid. In these applications, the focus is more on the functional properties of mercaptoethanol rather than its purity. The lower purity grade is also more cost-effective, making it an attractive option for industries where cost considerations are critical. The choice between above 99% and below 99% purity mercaptoethanol depends largely on the specific requirements of the application and the cost constraints of the industry. For instance, in agrochemicals, where mercaptoethanol is used as an intermediate in the synthesis of pesticides and herbicides, the purity requirements may vary depending on the specific chemical processes involved. In some cases, a lower purity grade may suffice, while in others, a higher purity grade may be necessary to ensure the desired chemical reactions occur efficiently. Moreover, the availability and cost of raw materials, as well as the production processes involved, also play a role in determining the purity grade of mercaptoethanol that is used. Manufacturers must balance the need for high purity with the economic feasibility of producing or sourcing such a product. This balance is crucial in maintaining competitiveness in the market while meeting the quality standards required by different industries. In summary, the distinction between above 99% and below 99% purity mercaptoethanol is a critical consideration in the global mercaptoethanol market. It affects not only the applications and industries that utilize this compound but also the pricing and market dynamics. As industries continue to evolve and new applications for mercaptoethanol are discovered, the demand for different purity grades may shift, reflecting changes in technological requirements and economic conditions. Understanding these nuances is essential for stakeholders in the mercaptoethanol market to make informed decisions and capitalize on emerging opportunities.

Consumer & Industrial Applications, Agrochemicals, Polymers and Rubber Applications, Water Treatment Applications, Other in the Global Mercaptoethanol Market:

Mercaptoethanol finds diverse applications across various sectors, each leveraging its unique chemical properties to enhance product performance and process efficiency. In consumer and industrial applications, mercaptoethanol is primarily used as a stabilizer and reducing agent. Its ability to break disulfide bonds makes it invaluable in the production of cosmetics and personal care products, where it helps in maintaining the stability and shelf-life of formulations. Additionally, in industrial settings, it is used in the manufacturing of adhesives and sealants, contributing to the durability and effectiveness of these products. In the agrochemical sector, mercaptoethanol plays a crucial role as an intermediate in the synthesis of pesticides and herbicides. Its chemical properties facilitate the production of active ingredients that are essential for effective pest and weed control. This application is particularly important in agriculture, where the demand for efficient and sustainable crop protection solutions is on the rise. Mercaptoethanol's role in this sector underscores its importance in supporting global food security and agricultural productivity. The polymers and rubber industry also benefits significantly from the use of mercaptoethanol. In these applications, it acts as a chain transfer agent, helping to control the molecular weight of polymers during the polymerization process. This is critical in producing materials with specific mechanical and physical properties, such as flexibility, strength, and resistance to environmental factors. In rubber manufacturing, mercaptoethanol is used to improve the processing and performance characteristics of rubber products, making them suitable for a wide range of applications, from automotive components to consumer goods. Water treatment is another area where mercaptoethanol is utilized, primarily for its reducing properties. It is used to remove heavy metals and other contaminants from water, contributing to the production of clean and safe water for industrial and municipal use. This application highlights mercaptoethanol's role in environmental management and its contribution to sustainable practices in water treatment. Beyond these specific applications, mercaptoethanol is also used in various other sectors, including electronics, textiles, and pharmaceuticals. In electronics, it is used in the production of semiconductors and other electronic components, where its reducing properties are essential for certain manufacturing processes. In textiles, mercaptoethanol is used in dyeing and finishing processes to enhance the quality and durability of fabrics. In pharmaceuticals, it is used in the synthesis of certain drugs and as a stabilizer in formulations, ensuring the safety and efficacy of pharmaceutical products. Overall, the versatility of mercaptoethanol makes it a valuable component in numerous industries, each benefiting from its unique chemical properties. As industries continue to innovate and seek more efficient and sustainable solutions, the demand for mercaptoethanol is likely to grow, reflecting its critical role in modern industrial processes.

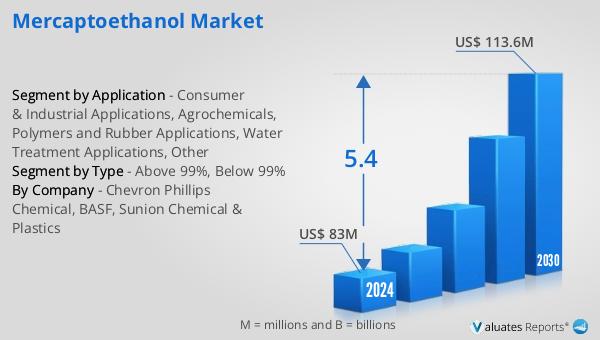

Global Mercaptoethanol Market Outlook:

The outlook for the global mercaptoethanol market indicates a promising growth trajectory over the coming years. Starting from a valuation of approximately $83 million in 2024, the market is expected to expand to around $113.6 million by 2030. This growth is projected to occur at a compound annual growth rate (CAGR) of 5.4% throughout the forecast period. This upward trend can be attributed to several factors, including the increasing demand for mercaptoethanol in various industrial applications, such as pharmaceuticals, agrochemicals, and water treatment. The compound's unique properties, such as its ability to act as a reducing agent and stabilizer, make it indispensable in these sectors, driving its demand. Moreover, the growth of end-use industries, particularly in emerging markets, is likely to contribute to the expansion of the mercaptoethanol market. As these industries continue to develop and innovate, the need for high-quality and efficient chemical compounds like mercaptoethanol will increase, further fueling market growth. Additionally, advancements in production technologies and the development of new applications for mercaptoethanol are expected to create new opportunities for market players. However, the market may also face challenges, such as regulatory constraints and the availability of alternative compounds that could potentially replace mercaptoethanol in certain applications. Despite these challenges, the overall outlook for the mercaptoethanol market remains positive, with steady growth anticipated over the forecast period. This growth reflects the compound's essential role in various industrial processes and its continued relevance in a rapidly evolving global market.

| Report Metric | Details |

| Report Name | Mercaptoethanol Market |

| Accounted market size in 2024 | US$ 83 million |

| Forecasted market size in 2030 | US$ 113.6 million |

| CAGR | 5.4 |

| Base Year | 2024 |

| Forecasted years | 2025 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | Chevron Phillips Chemical, BASF, Sunion Chemical & Plastics |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |