What is Global Maritime Fender Market?

The Global Maritime Fender Market is an essential component of the maritime industry, providing critical protection to vessels and port infrastructure. Maritime fenders are devices used to absorb the kinetic energy of a vessel berthing against a jetty, quay wall, or another vessel, thereby preventing damage to both the vessel and the docking structure. These fenders are crucial for ensuring the safety and efficiency of maritime operations, particularly in busy ports and harbors where vessels of various sizes and types frequently dock. The market for maritime fenders is driven by the increasing global trade and the expansion of port infrastructure to accommodate larger vessels. Additionally, the growing emphasis on maritime safety and environmental protection has led to the development of more advanced and durable fender systems. The market encompasses a wide range of fender types, including solid rubber fenders, pneumatic fenders, and foam fenders, each designed to meet specific operational requirements. As the maritime industry continues to evolve, the demand for reliable and efficient fender systems is expected to grow, making the Global Maritime Fender Market a vital segment of the broader maritime industry.

Solid Rubber Fenders, Pneumatic Fenders, Foam Fenders in the Global Maritime Fender Market:

Solid rubber fenders, pneumatic fenders, and foam fenders are the primary types of fenders used in the Global Maritime Fender Market, each offering unique benefits and applications. Solid rubber fenders are made from high-quality rubber materials and are known for their durability and resistance to harsh marine environments. These fenders are typically used in ports and harbors where they provide robust protection against the impact of docking vessels. They come in various shapes and sizes, including cylindrical, cone, and cell fenders, allowing them to be tailored to specific docking requirements. Solid rubber fenders are particularly favored for their low maintenance needs and long service life, making them a cost-effective solution for many maritime applications. Pneumatic fenders, on the other hand, are inflatable fenders that provide a high degree of flexibility and energy absorption. They are commonly used for ship-to-ship transfers and in situations where vessels need to dock at varying heights due to tidal changes. The air-filled design of pneumatic fenders allows them to adapt to different docking conditions, providing consistent protection across a wide range of scenarios. These fenders are also easy to deploy and retrieve, making them a popular choice for temporary or emergency docking situations. Foam fenders are another type of fender used in the maritime industry, known for their lightweight and high energy absorption capabilities. Made from closed-cell foam, these fenders are designed to withstand repeated impacts without losing their shape or effectiveness. Foam fenders are often used in areas where space is limited, as their compact design allows for easy installation and storage. They are also resistant to environmental factors such as UV radiation and saltwater, ensuring long-lasting performance in challenging marine conditions. Each of these fender types plays a crucial role in the Global Maritime Fender Market, providing essential protection for vessels and port infrastructure. As the maritime industry continues to grow and evolve, the demand for advanced fender systems that offer enhanced performance and reliability is expected to increase, driving innovation and development within this market segment.

Large Tankers, Shipping Ships, Yacht, Offshore Vessels, Others in the Global Maritime Fender Market:

The Global Maritime Fender Market plays a vital role in various maritime applications, including large tankers, shipping ships, yachts, offshore vessels, and other specialized vessels. Large tankers, which transport vast quantities of oil, gas, and other bulk liquids, rely heavily on robust fender systems to ensure safe docking and undocking operations. The sheer size and weight of these vessels mean that any impact during berthing can result in significant damage, making high-performance fenders essential for protecting both the tanker and the docking infrastructure. Shipping ships, which include container ships and cargo vessels, also benefit from advanced fender systems. These vessels often operate on tight schedules and require efficient docking procedures to minimize turnaround times. Reliable fender systems help facilitate smooth berthing operations, reducing the risk of delays and ensuring the safe handling of goods. Yachts, although smaller in size compared to commercial vessels, also require effective fender systems to protect their hulls from damage during docking. The aesthetic and structural integrity of yachts is of utmost importance to their owners, making high-quality fenders a crucial investment for yacht operators. Offshore vessels, which operate in challenging environments such as oil rigs and wind farms, depend on durable fender systems to withstand harsh conditions and ensure safe operations. These vessels often face rough seas and strong winds, making reliable fender systems essential for maintaining stability and preventing damage. Other specialized vessels, such as ferries and cruise ships, also utilize maritime fenders to enhance safety and efficiency during docking operations. The diverse range of applications for maritime fenders highlights their importance in the maritime industry, providing essential protection and facilitating smooth operations across various vessel types. As the demand for maritime transportation continues to grow, the need for advanced fender systems that offer enhanced performance and reliability is expected to increase, driving further innovation and development within the Global Maritime Fender Market.

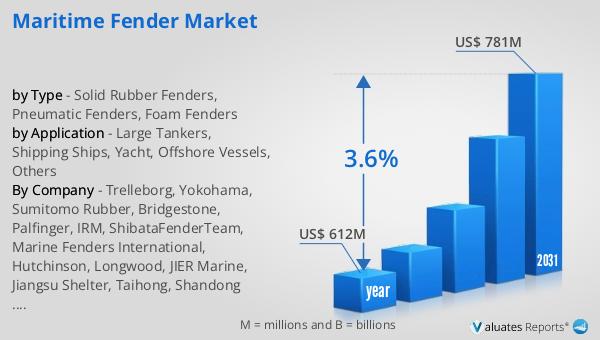

Global Maritime Fender Market Outlook:

The global market for maritime fenders was valued at $612 million in 2024 and is anticipated to grow to a revised size of $781 million by 2031, reflecting a compound annual growth rate (CAGR) of 3.6% over the forecast period. This growth is indicative of the increasing demand for maritime fenders driven by the expansion of global trade and the need for enhanced maritime safety. As ports and harbors around the world continue to upgrade their infrastructure to accommodate larger vessels, the demand for reliable and efficient fender systems is expected to rise. The market's growth is also supported by advancements in fender technology, which have led to the development of more durable and effective fender solutions. These innovations are crucial for meeting the evolving needs of the maritime industry, particularly in light of the growing emphasis on environmental protection and sustainability. The projected growth of the Global Maritime Fender Market underscores the importance of fender systems in ensuring the safety and efficiency of maritime operations. As the industry continues to evolve, the demand for advanced fender solutions that offer enhanced performance and reliability is expected to drive further growth and development within this market segment.

| Report Metric | Details |

| Report Name | Maritime Fender Market |

| Accounted market size in year | US$ 612 million |

| Forecasted market size in 2031 | US$ 781 million |

| CAGR | 3.6% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Trelleborg, Yokohama, Sumitomo Rubber, Bridgestone, Palfinger, IRM, ShibataFenderTeam, Marine Fenders International, Hutchinson, Longwood, JIER Marine, Jiangsu Shelter, Taihong, Shandong Nanhai Airbag Engineering, Qingdao Tiandun, Evergreen, Zhaoyuan Talent Plastic, Jiangyin Hengsheng, Tonly |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |