What is Global Magnetic Fluid Feedthroughs Market?

The Global Magnetic Fluid Feedthroughs Market is a specialized segment within the broader industrial and technological landscape, focusing on the development and application of magnetic fluid feedthroughs. These devices are crucial for maintaining a vacuum seal while allowing the transfer of mechanical motion or electrical signals across a barrier. The market is driven by the increasing demand for high-precision and reliable sealing solutions in various industries, including semiconductor manufacturing, industrial machinery, and energy production. Magnetic fluid feedthroughs utilize a ferrofluid—a liquid that becomes strongly magnetized in the presence of a magnetic field—to create a seal that is both flexible and robust. This technology is particularly valued for its ability to operate in extreme conditions, such as high vacuum or high-pressure environments, making it indispensable in cutting-edge applications. As industries continue to push the boundaries of technology, the demand for advanced sealing solutions like magnetic fluid feedthroughs is expected to grow, driven by the need for efficiency, reliability, and performance in critical operations. The market's growth is also supported by ongoing research and development efforts aimed at enhancing the capabilities and applications of these devices.

Magnetic Rotary Feedthrough, Magnetic Linear Feedthrough, Magnetic Linear-Rotary Feedthrough in the Global Magnetic Fluid Feedthroughs Market:

Magnetic Rotary Feedthroughs, Magnetic Linear Feedthroughs, and Magnetic Linear-Rotary Feedthroughs are integral components of the Global Magnetic Fluid Feedthroughs Market, each serving distinct functions and applications. Magnetic Rotary Feedthroughs are designed to transmit rotational motion across a vacuum or pressure boundary. They are commonly used in applications where precise rotational movement is required, such as in semiconductor manufacturing equipment and scientific instruments. These feedthroughs leverage the properties of ferrofluids to maintain a vacuum seal while allowing for smooth and continuous rotation, ensuring high performance and reliability in demanding environments. On the other hand, Magnetic Linear Feedthroughs are engineered to facilitate linear motion across a sealed boundary. They are essential in applications where linear displacement is necessary, such as in industrial automation and robotics. By utilizing magnetic fluids, these feedthroughs provide a seamless and frictionless motion, enhancing the efficiency and longevity of the equipment they are integrated into. Magnetic Linear-Rotary Feedthroughs combine the capabilities of both rotary and linear feedthroughs, offering a versatile solution for applications that require both types of motion. These hybrid feedthroughs are particularly valuable in complex machinery and equipment where multi-axis movement is essential. The integration of magnetic fluid technology in these feedthroughs ensures that they can operate effectively in harsh environments, providing a reliable and durable solution for various industrial and technological applications. As the demand for precision and efficiency continues to rise across industries, the role of these magnetic feedthroughs becomes increasingly critical, driving innovation and growth within the Global Magnetic Fluid Feedthroughs Market.

Semiconductor Processing Equipment, Industrial Equipment, Power Generation Measurement and Control, Photovoltaics, Display & LED, Others in the Global Magnetic Fluid Feedthroughs Market:

The Global Magnetic Fluid Feedthroughs Market finds extensive application across several key areas, including Semiconductor Processing Equipment, Industrial Equipment, Power Generation Measurement and Control, Photovoltaics, Display & LED, and other sectors. In the realm of Semiconductor Processing Equipment, magnetic fluid feedthroughs are essential for maintaining the integrity of vacuum environments while allowing for the precise movement and control of components. This is crucial in the fabrication of semiconductors, where even the slightest contamination can lead to defects in the final product. In Industrial Equipment, these feedthroughs are used to enhance the performance and reliability of machinery by providing robust sealing solutions that can withstand harsh operating conditions. This is particularly important in industries such as automotive manufacturing and aerospace, where equipment is subjected to extreme pressures and temperatures. In Power Generation Measurement and Control, magnetic fluid feedthroughs play a vital role in ensuring the accurate monitoring and regulation of power systems. They enable the seamless transmission of signals and mechanical motion across sealed boundaries, which is critical for maintaining the efficiency and safety of power generation facilities. In the Photovoltaics sector, these feedthroughs are used to improve the manufacturing processes of solar panels by providing reliable sealing solutions that can withstand the high temperatures and pressures involved in production. Similarly, in the Display & LED industry, magnetic fluid feedthroughs are utilized to enhance the precision and efficiency of manufacturing processes, ensuring the production of high-quality displays and lighting solutions. Beyond these specific applications, magnetic fluid feedthroughs are also used in a variety of other sectors, including medical equipment, scientific research, and telecommunications, where their ability to provide reliable and efficient sealing solutions is highly valued. As industries continue to evolve and demand more advanced technologies, the Global Magnetic Fluid Feedthroughs Market is poised to play a crucial role in supporting innovation and growth across these diverse fields.

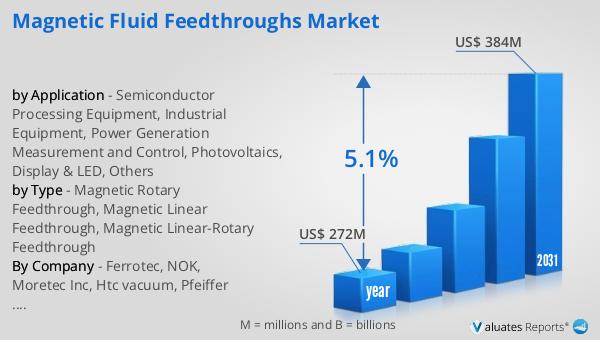

Global Magnetic Fluid Feedthroughs Market Outlook:

The global market for Magnetic Fluid Feedthroughs was valued at $272 million in 2024 and is anticipated to expand to $384 million by 2031, reflecting a compound annual growth rate (CAGR) of 5.1% over the forecast period. This growth is indicative of the increasing demand for advanced sealing solutions across various industries. In parallel, the global semiconductor market was valued at $526.8 billion in 2023 and is projected to reach $780.7 billion by 2030. This growth trajectory underscores the critical role of semiconductor technology in driving innovation and economic development worldwide. Furthermore, the semiconductor manufacturing (wafer fabrication) market is expected to grow from $251.7 billion in 2023 to $506.5 billion by 2030, with a remarkable CAGR of 40.49% during the forecast period. This rapid expansion highlights the escalating demand for semiconductors, driven by advancements in technology and the increasing integration of electronic components in various applications. The growth of these markets is closely intertwined, as the demand for magnetic fluid feedthroughs is largely driven by the needs of the semiconductor industry, among others. As these industries continue to evolve and expand, the Global Magnetic Fluid Feedthroughs Market is expected to play a pivotal role in supporting their growth and development.

| Report Metric | Details |

| Report Name | Magnetic Fluid Feedthroughs Market |

| Accounted market size in year | US$ 272 million |

| Forecasted market size in 2031 | US$ 384 million |

| CAGR | 5.1% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Ferrotec, NOK, Moretec Inc, Htc vacuum, Pfeiffer Vacuum, KSM, Eagle Industry, Fermi Instruments, VacSol GmbH, Kurt J. Lesker Company, IRIE KOKEN CO.,LTD, MDC Precision, Allectra, National Electrostatics Corp., Thermionics Laboratory, Applied Nano Technology Science, Inc. (ANTS), Rigaku Holdings, Inficon, CeramTec, FerroLabs, Inc., MPF Products, Inc., Magron, ANZ Corporation, Vic Ferrofluidics Co., Ltd, Hefei Anze Welding Ripple Tube, Hangzhou Vigor Magnetic&Electronic Technology, Zigong Zhaoqiang Sealing Products Industrial, Beijing Shenran Magnetism Fluid Technology, Zhejiang Jingsheng Mechanical and Electrical |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |