What is Global Industrial Robotic Motor Market?

The Global Industrial Robotic Motor Market refers to the sector that deals with the production and distribution of motors specifically designed for industrial robots. These motors are crucial components that enable robots to perform precise and complex tasks in various industrial applications. The market encompasses a wide range of motor types, including servo motors, DC motors, and stepper motors, each offering unique advantages for different robotic applications. As industries increasingly adopt automation to enhance efficiency and productivity, the demand for industrial robotic motors is on the rise. These motors are integral to the functioning of robots used in manufacturing, assembly, packaging, and other industrial processes. The market is characterized by continuous advancements in motor technology, aimed at improving performance, energy efficiency, and reliability. With the growing emphasis on smart manufacturing and Industry 4.0, the Global Industrial Robotic Motor Market is poised for significant growth, driven by the need for more sophisticated and adaptable robotic solutions. This market plays a vital role in supporting the automation revolution, enabling industries to achieve higher levels of precision, speed, and flexibility in their operations.

Servo Motor, DC Motor, Stepper Motor in the Global Industrial Robotic Motor Market:

Servo motors, DC motors, and stepper motors are pivotal components in the Global Industrial Robotic Motor Market, each serving distinct roles in the operation of industrial robots. Servo motors are renowned for their precision and control, making them ideal for applications requiring high accuracy and dynamic response. These motors are equipped with feedback systems that allow for precise control of position, speed, and torque, making them indispensable in robotics where exact movements are crucial. Servo motors are commonly used in articulated robots, which require intricate and fluid motion to perform tasks such as welding, painting, and assembly. Their ability to provide smooth and controlled motion makes them a preferred choice in industries where precision is paramount. DC motors, on the other hand, are valued for their simplicity and cost-effectiveness. They operate on direct current and are known for their high starting torque and ease of speed control. DC motors are often used in applications where speed variation and control are essential, such as in conveyor systems and simple robotic arms. Their straightforward design and operation make them suitable for tasks that do not require the high precision offered by servo motors. In the context of industrial robotics, DC motors are often found in Cartesian or gantry robots, where linear motion and straightforward tasks are the primary requirements. Stepper motors are another critical component in the industrial robotic motor landscape. These motors are designed to move in discrete steps, allowing for precise control of angular position without the need for feedback systems. This makes stepper motors ideal for applications where precise positioning is required, but the complexity and cost of servo motors are not justified. Stepper motors are commonly used in SCARA robots, which are employed in pick-and-place tasks, assembly operations, and other applications where repetitive and precise movements are necessary. The ability of stepper motors to maintain position without feedback makes them a cost-effective solution for many industrial applications. In summary, the Global Industrial Robotic Motor Market is driven by the diverse needs of industrial automation, with servo motors, DC motors, and stepper motors each playing a crucial role. Servo motors offer unparalleled precision and control, making them suitable for complex and dynamic tasks. DC motors provide a cost-effective solution for applications requiring speed control and high torque. Stepper motors offer precise positioning capabilities without the need for feedback, making them ideal for repetitive and straightforward tasks. As industries continue to embrace automation, the demand for these motors is expected to grow, driven by the need for efficient, reliable, and adaptable robotic solutions.

SCARA Robot, Delta Robot, Cartesian/Gantry Robot, Articulated Robot, Other in the Global Industrial Robotic Motor Market:

The Global Industrial Robotic Motor Market finds its application in various types of robots, each designed for specific tasks and industries. SCARA robots, known for their Selective Compliance Assembly Robot Arm design, are widely used in assembly and pick-and-place operations. These robots benefit from the precision and speed offered by servo motors, which enable them to perform tasks with high accuracy and efficiency. SCARA robots are commonly employed in the electronics industry for assembling small components, where their ability to move quickly and accurately is crucial. Delta robots, characterized by their parallel arm design, are another significant application area for industrial robotic motors. These robots are known for their high-speed capabilities and are often used in packaging and sorting applications. The rapid and precise movements required by delta robots are typically powered by servo motors, which provide the necessary control and speed. The food and beverage industry frequently utilizes delta robots for tasks such as sorting and packaging, where speed and hygiene are critical considerations. Cartesian or gantry robots, which operate on three linear axes, are used in applications requiring straightforward linear motion. These robots often employ DC motors due to their simplicity and ease of control. Cartesian robots are commonly found in applications such as CNC machining, 3D printing, and material handling, where precise linear motion is essential. The straightforward design of DC motors makes them well-suited for the linear and repetitive tasks performed by Cartesian robots. Articulated robots, with their multi-jointed arm design, are among the most versatile types of industrial robots. These robots are used in a wide range of applications, from welding and painting to assembly and material handling. The complex and fluid movements required by articulated robots are typically powered by servo motors, which provide the precision and control necessary for these tasks. The automotive industry is a major user of articulated robots, employing them for tasks such as welding and assembly, where precision and flexibility are paramount. In addition to these specific robot types, the Global Industrial Robotic Motor Market also serves other robotic applications, including collaborative robots (cobots) and mobile robots. Cobots, designed to work alongside humans, often use a combination of motor types to achieve the necessary balance of precision, speed, and safety. Mobile robots, used in logistics and warehousing, rely on motors to provide the mobility and control required for navigating complex environments. The diverse applications of industrial robotic motors highlight their critical role in enabling automation across various industries, driving efficiency, productivity, and innovation.

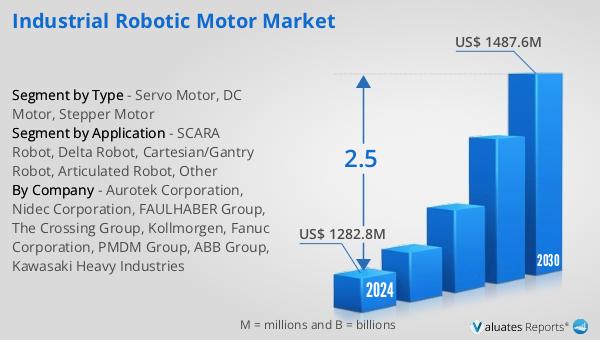

Global Industrial Robotic Motor Market Outlook:

The outlook for the Global Industrial Robotic Motor Market indicates a steady growth trajectory over the coming years. The market is anticipated to expand from a valuation of US$ 1282.8 million in 2024 to US$ 1487.6 million by 2030. This growth is expected to occur at a Compound Annual Growth Rate (CAGR) of 2.5% during the forecast period. This projected growth reflects the increasing adoption of automation technologies across various industries, driven by the need for enhanced efficiency, precision, and productivity. As industries continue to embrace automation, the demand for industrial robotic motors is likely to rise, supported by advancements in motor technology and the growing emphasis on smart manufacturing and Industry 4.0. The market's expansion is also attributed to the rising demand for more sophisticated and adaptable robotic solutions, capable of meeting the evolving needs of modern manufacturing and industrial processes. The Global Industrial Robotic Motor Market plays a crucial role in supporting the automation revolution, enabling industries to achieve higher levels of precision, speed, and flexibility in their operations. As the market continues to grow, it is expected to drive innovation and development in motor technology, further enhancing the capabilities and applications of industrial robots.

| Report Metric | Details |

| Report Name | Industrial Robotic Motor Market |

| Accounted market size in 2024 | US$ 1282.8 million |

| Forecasted market size in 2030 | US$ 1487.6 million |

| CAGR | 2.5 |

| Base Year | 2024 |

| Forecasted years | 2025 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | Aurotek Corporation, Nidec Corporation, FAULHABER Group, The Crossing Group, Kollmorgen, Fanuc Corporation, PMDM Group, ABB Group, Kawasaki Heavy Industries |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |