What is Global Industrial Automatic Control System Device Market?

The Global Industrial Automatic Control System Device Market is a rapidly evolving sector that plays a crucial role in enhancing the efficiency and productivity of various industries worldwide. These systems are designed to automate and control industrial processes, reducing the need for human intervention and minimizing errors. They encompass a wide range of devices and technologies, including sensors, controllers, and software, which work together to monitor and manage industrial operations. The market is driven by the increasing demand for automation in industries such as manufacturing, energy, and transportation, where precision and reliability are paramount. As industries strive to improve operational efficiency and reduce costs, the adoption of automatic control systems is becoming increasingly prevalent. These systems not only enhance productivity but also contribute to improved safety and environmental sustainability by optimizing resource usage and minimizing waste. The market is characterized by continuous technological advancements, with companies investing heavily in research and development to introduce innovative solutions that cater to the evolving needs of various industries. As a result, the Global Industrial Automatic Control System Device Market is poised for significant growth in the coming years, offering numerous opportunities for businesses and investors alike.

Control System Device, Drive System Device, Execution System Device, Feedback System Device in the Global Industrial Automatic Control System Device Market:

Control System Devices are the backbone of the Global Industrial Automatic Control System Device Market, serving as the central hub for managing and directing industrial processes. These devices include programmable logic controllers (PLCs), distributed control systems (DCS), and supervisory control and data acquisition (SCADA) systems. PLCs are used for automating specific processes, such as assembly lines or robotic devices, by executing pre-programmed instructions. DCS, on the other hand, are employed in large-scale operations, providing centralized control over complex processes by distributing control functions across various subsystems. SCADA systems are essential for real-time monitoring and control of industrial processes, enabling operators to make informed decisions based on data collected from sensors and other devices. Drive System Devices are integral components that convert electrical energy into mechanical energy, facilitating the movement and operation of machinery. These devices include motors, actuators, and variable frequency drives (VFDs), which are used to control the speed and torque of machines, ensuring optimal performance and energy efficiency. Execution System Devices are responsible for carrying out specific tasks within an industrial process, such as cutting, welding, or painting. These devices are often integrated with control systems to ensure precise and accurate execution of tasks, minimizing errors and improving overall productivity. Feedback System Devices play a critical role in maintaining the stability and accuracy of industrial processes by providing real-time data on the performance of machines and systems. These devices include sensors, transducers, and feedback controllers, which continuously monitor variables such as temperature, pressure, and speed, and adjust the control systems accordingly to maintain optimal conditions. Together, these devices form a comprehensive ecosystem that enables industries to automate and optimize their operations, leading to increased efficiency, reduced costs, and improved product quality.

Electronics Manufacturing Industry, Textile Equipment Industry, Chemical Industry, Others in the Global Industrial Automatic Control System Device Market:

The Global Industrial Automatic Control System Device Market finds extensive applications across various industries, including electronics manufacturing, textile equipment, chemical, and others. In the electronics manufacturing industry, these systems are used to automate assembly lines, ensuring precision and consistency in the production of electronic components and devices. By automating repetitive tasks, such as soldering and component placement, these systems reduce the risk of human error and enhance production speed, leading to increased output and reduced costs. In the textile equipment industry, automatic control systems are employed to manage and optimize processes such as spinning, weaving, and dyeing. These systems ensure uniformity and quality in textile production by precisely controlling variables such as tension, speed, and temperature. In the chemical industry, automatic control systems are crucial for maintaining the safety and efficiency of chemical processes. They monitor and control variables such as pressure, temperature, and flow rates, ensuring that chemical reactions occur under optimal conditions and minimizing the risk of accidents. Additionally, these systems enable real-time monitoring and data analysis, allowing operators to make informed decisions and quickly respond to any deviations from the desired process parameters. Beyond these industries, automatic control systems are also used in sectors such as food and beverage, pharmaceuticals, and automotive, where they contribute to improved product quality, operational efficiency, and regulatory compliance. By automating complex and repetitive tasks, these systems free up human resources for more strategic and value-added activities, ultimately driving innovation and growth across various industries.

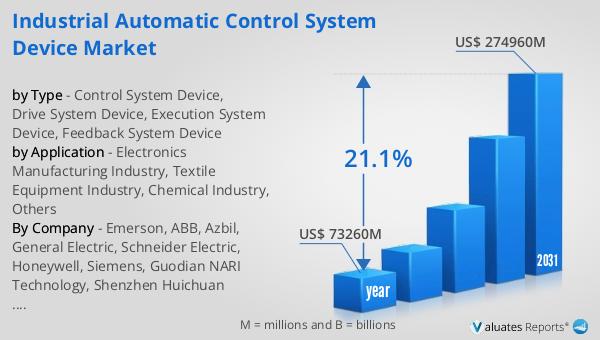

Global Industrial Automatic Control System Device Market Outlook:

The outlook for the Global Industrial Automatic Control System Device Market is promising, with significant growth anticipated over the coming years. In 2024, the market was valued at approximately US$ 73,260 million, reflecting the increasing demand for automation solutions across various industries. By 2031, the market is expected to expand to a revised size of US$ 274,960 million, driven by a compound annual growth rate (CAGR) of 21.1% during the forecast period. This robust growth can be attributed to several factors, including the rising need for operational efficiency, cost reduction, and enhanced safety in industrial processes. As industries continue to embrace digital transformation and automation, the demand for advanced control system devices is expected to surge. Companies are investing heavily in research and development to introduce innovative solutions that cater to the evolving needs of their customers, further fueling market growth. Additionally, the increasing adoption of Industry 4.0 technologies, such as the Internet of Things (IoT) and artificial intelligence (AI), is expected to drive the demand for sophisticated control systems that can seamlessly integrate with these technologies. As a result, the Global Industrial Automatic Control System Device Market is poised for substantial growth, offering numerous opportunities for businesses and investors to capitalize on this expanding market.

| Report Metric | Details |

| Report Name | Industrial Automatic Control System Device Market |

| Accounted market size in year | US$ 73260 million |

| Forecasted market size in 2031 | US$ 274960 million |

| CAGR | 21.1% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Emerson, ABB, Azbil, General Electric, Schneider Electric, Honeywell, Siemens, Guodian NARI Technology, Shenzhen Huichuan Technology, Guodian Nanjing Automation, Chongqing Chuanyi Automation, Shanghai Xinshida Electric, Shenzhen INVT Electric, Guangzhou Zhiguang Electric, Shenzhen Hopewind Electric, Beijing Dahao Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |