What is Global High Purity Stainless Steel Ball Valve Market?

The Global High Purity Stainless Steel Ball Valve Market is a specialized segment within the broader valve industry, focusing on valves made from high-grade stainless steel that meet stringent purity standards. These valves are essential in industries where contamination must be minimized, such as pharmaceuticals, food and beverage, and semiconductors. High purity stainless steel ball valves are designed to handle corrosive and high-pressure environments, ensuring reliability and longevity. They are characterized by their ability to maintain a clean and sterile flow path, which is crucial in applications where hygiene and precision are paramount. The market for these valves is driven by the increasing demand for high-quality, durable, and efficient flow control solutions in various industrial applications. As industries continue to evolve and require more sophisticated equipment, the demand for high purity stainless steel ball valves is expected to grow, driven by advancements in technology and the need for improved operational efficiency. These valves are not only vital for maintaining product integrity but also for ensuring compliance with industry regulations and standards. The market's growth is supported by ongoing research and development efforts aimed at enhancing valve performance and expanding their application scope.

V-Port Ball Valve, Full Port Ball Valve, Multi-port Ball Valve, Standard Port Ball Valve, Reduced Port Ball Valve, Others in the Global High Purity Stainless Steel Ball Valve Market:

In the realm of high purity stainless steel ball valves, several types cater to different industrial needs, each with unique features and applications. V-Port Ball Valves are designed with a V-shaped notch in the ball, allowing for precise flow control. This design is particularly useful in applications requiring accurate flow regulation, such as in chemical processing or water treatment. The V-Port design enables the valve to handle varying flow rates and pressures, making it versatile and efficient. Full Port Ball Valves, on the other hand, have a larger opening, equal to the pipe diameter, which minimizes pressure drop and allows for maximum flow. This makes them ideal for applications where maintaining high flow rates is critical, such as in oil and gas pipelines. Multi-port Ball Valves feature multiple ports, allowing for the diversion of flow in different directions. This capability is beneficial in complex piping systems where flow needs to be redirected without installing multiple valves. Standard Port Ball Valves have a smaller opening compared to full port valves, resulting in a slight pressure drop. They are suitable for applications where space is limited, and the pressure drop is not a significant concern. Reduced Port Ball Valves, also known as reduced bore valves, have an even smaller opening, which restricts flow to a greater extent. These are used in applications where flow reduction is necessary, such as in certain chemical processes. Other types of ball valves in the high purity stainless steel category include specialized designs tailored for specific industries, such as those with enhanced corrosion resistance or those designed for high-temperature applications. Each type of valve offers distinct advantages and is selected based on the specific requirements of the application, ensuring optimal performance and efficiency. The choice of valve type is influenced by factors such as the nature of the fluid being handled, the operating environment, and the desired level of flow control. As industries continue to demand more sophisticated and reliable flow control solutions, the development and refinement of these valve types remain a key focus for manufacturers.

Pharmaceutical, Chemical, Oil and Gas, Water Treatment, Semiconductor Industry, HVAC, Food & Beverage, Others in the Global High Purity Stainless Steel Ball Valve Market:

High purity stainless steel ball valves play a crucial role in various industries, each with specific requirements and challenges. In the pharmaceutical industry, these valves are essential for maintaining the sterility and purity of products. They are used in processes such as drug manufacturing and formulation, where contamination must be avoided at all costs. The chemical industry relies on these valves for handling corrosive and hazardous substances, ensuring safe and efficient processing. In the oil and gas sector, high purity stainless steel ball valves are used in pipelines and refineries to control the flow of crude oil and natural gas, where durability and reliability are paramount. Water treatment facilities utilize these valves to manage the flow of water and chemicals, ensuring clean and safe water supply. The semiconductor industry demands high purity valves to prevent contamination during the manufacturing of sensitive electronic components. In HVAC systems, these valves help regulate the flow of heating and cooling fluids, contributing to energy efficiency and system performance. The food and beverage industry uses high purity stainless steel ball valves to maintain hygiene and prevent contamination during the processing and packaging of products. Other industries, such as biotechnology and aerospace, also benefit from the use of these valves, where precision and reliability are critical. The versatility and robustness of high purity stainless steel ball valves make them indispensable across these diverse applications, supporting operational efficiency and compliance with industry standards. As industries continue to evolve and face new challenges, the demand for high-quality, reliable flow control solutions like high purity stainless steel ball valves is expected to grow, driven by the need for improved performance and safety.

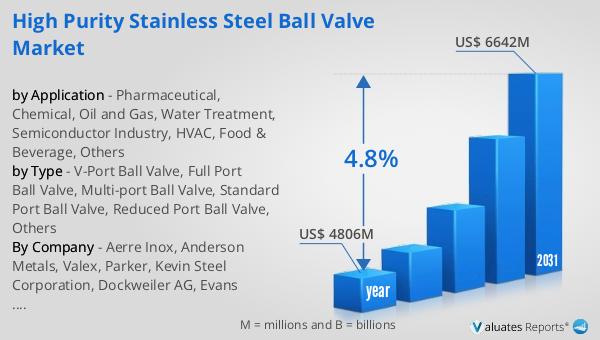

Global High Purity Stainless Steel Ball Valve Market Outlook:

The global market for High Purity Stainless Steel Ball Valves was valued at $4,806 million in 2024 and is anticipated to expand to a revised size of $6,642 million by 2031, reflecting a compound annual growth rate (CAGR) of 4.8% during the forecast period. This growth trajectory underscores the increasing demand for high-quality, durable, and efficient flow control solutions across various industries. The market's expansion is driven by the need for valves that can withstand harsh environments and maintain high levels of purity and reliability. As industries such as pharmaceuticals, oil and gas, and semiconductors continue to grow and evolve, the demand for high purity stainless steel ball valves is expected to rise. These valves are essential for ensuring operational efficiency, product integrity, and compliance with stringent industry standards. The projected growth of the market highlights the importance of ongoing research and development efforts aimed at enhancing valve performance and expanding their application scope. As manufacturers continue to innovate and develop new technologies, the market for high purity stainless steel ball valves is poised for significant growth, driven by the need for advanced flow control solutions in an increasingly complex industrial landscape.

| Report Metric | Details |

| Report Name | High Purity Stainless Steel Ball Valve Market |

| Accounted market size in year | US$ 4806 million |

| Forecasted market size in 2031 | US$ 6642 million |

| CAGR | 4.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Aerre Inox, Anderson Metals, Valex, Parker, Kevin Steel Corporation, Dockweiler AG, Evans Components, CSE Chiang Sung Enterprise, GEMU Group, Fujikin, Modentic, Zhejiang Aomi Fluid Equipment Co., Ltd., Cipriani Harrison Valves, Valtorc, Mako Products, QSM Tru-Flo, Golden Highope Industrial INC., Zetco, Terofox, VIP Valves |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |