What is Global FC Underfills Market?

The Global FC Underfills Market is a specialized segment within the electronics industry that focuses on the use of underfill materials in flip-chip (FC) technology. Underfills are crucial in enhancing the reliability and performance of electronic packages by filling the gap between the chip and the substrate, thereby providing mechanical support and protecting against environmental stress. This market is driven by the increasing demand for miniaturized and high-performance electronic devices, which require advanced packaging solutions. The growth of the semiconductor industry, coupled with advancements in electronic devices, has led to a surge in the adoption of FC underfills. These materials are essential in ensuring the longevity and durability of electronic components, especially in applications where thermal and mechanical stresses are prevalent. As technology continues to evolve, the need for efficient and reliable underfill solutions becomes more pronounced, making the Global FC Underfills Market a critical area of focus for manufacturers and researchers alike. The market is characterized by continuous innovation and development, as companies strive to meet the ever-changing demands of the electronics industry.

FC BGA, FC PGA, FC LGA, FC CSP, Others in the Global FC Underfills Market:

FC BGA (Ball Grid Array), FC PGA (Pin Grid Array), FC LGA (Land Grid Array), and FC CSP (Chip Scale Package) are different types of packaging technologies used in the Global FC Underfills Market. FC BGA is a type of surface-mount packaging that uses an array of solder balls to connect the chip to the substrate. This packaging is known for its high density and excellent thermal performance, making it suitable for high-performance applications. FC PGA, on the other hand, uses an array of pins to establish connections, offering flexibility in terms of socket compatibility and ease of replacement. This type of packaging is often used in processors and other high-end applications where performance and reliability are critical. FC LGA is similar to FC PGA but uses flat contacts instead of pins, providing a more robust connection and reducing the risk of damage during installation. This packaging is commonly used in applications where space is a constraint, and a reliable connection is essential. FC CSP is a miniaturized packaging solution that offers a smaller footprint and lower profile, making it ideal for portable and compact devices. This packaging is often used in consumer electronics, where size and weight are critical factors. Each of these packaging technologies has its unique advantages and is chosen based on the specific requirements of the application. The choice of packaging technology also influences the type of underfill material used, as different packages have different thermal and mechanical requirements. In the Global FC Underfills Market, manufacturers are continually developing new materials and technologies to meet the evolving needs of these packaging solutions. The market is characterized by a high level of competition, with companies striving to offer the most advanced and reliable underfill solutions. As electronic devices become more complex and demanding, the need for efficient and effective underfill materials becomes increasingly important. This has led to a surge in research and development activities, as companies seek to gain a competitive edge in the market. The Global FC Underfills Market is expected to continue growing as the demand for advanced packaging solutions increases, driven by the rapid advancements in technology and the increasing complexity of electronic devices.

Automotive, Telecommunication, Consumer Electronics, Other in the Global FC Underfills Market:

The usage of Global FC Underfills Market spans across various industries, including automotive, telecommunication, consumer electronics, and others. In the automotive industry, underfills are used in electronic control units (ECUs), sensors, and other critical components that require high reliability and durability. The harsh operating conditions in automotive applications, such as extreme temperatures and vibrations, necessitate the use of robust underfill materials to ensure the longevity and performance of electronic components. In the telecommunication sector, underfills are used in network infrastructure equipment, mobile devices, and other communication devices that require high-speed data processing and reliable performance. The increasing demand for high-speed internet and advanced communication technologies has led to a surge in the adoption of FC underfills in this industry. In consumer electronics, underfills are used in a wide range of devices, including smartphones, tablets, laptops, and wearable devices. The trend towards miniaturization and the need for high-performance devices have driven the demand for advanced underfill solutions in this sector. Underfills play a crucial role in enhancing the performance and reliability of consumer electronic devices, ensuring that they can withstand the rigors of daily use. Other industries, such as aerospace, medical devices, and industrial electronics, also utilize underfills to enhance the performance and reliability of their electronic components. In aerospace applications, underfills are used in avionics and other critical systems that require high reliability and performance. In medical devices, underfills are used in diagnostic equipment and other devices that require precision and reliability. In industrial electronics, underfills are used in control systems and other applications that require robust performance in harsh environments. The Global FC Underfills Market is characterized by a wide range of applications, each with its unique requirements and challenges. Manufacturers are continually developing new materials and technologies to meet the evolving needs of these industries, ensuring that their products can withstand the demands of modern electronic applications. The market is expected to continue growing as the demand for advanced electronic devices increases, driven by the rapid advancements in technology and the increasing complexity of electronic systems.

Global FC Underfills Market Outlook:

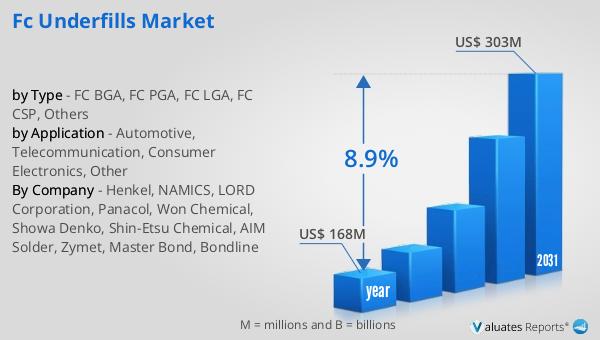

The global market for FC Underfills was valued at $168 million in 2024 and is anticipated to expand to a revised size of $303 million by 2031, reflecting a compound annual growth rate (CAGR) of 8.9% over the forecast period. This growth trajectory underscores the increasing demand for FC underfills across various industries, driven by the need for advanced packaging solutions that enhance the performance and reliability of electronic components. The market's expansion is fueled by the rapid advancements in technology and the growing complexity of electronic devices, which necessitate the use of robust and efficient underfill materials. As electronic devices become more sophisticated and demanding, the need for reliable underfill solutions becomes increasingly critical, driving the growth of the Global FC Underfills Market. The market is characterized by continuous innovation and development, as manufacturers strive to meet the ever-changing demands of the electronics industry. This growth is also supported by the increasing adoption of FC underfills in emerging markets, where the demand for advanced electronic devices is on the rise. The Global FC Underfills Market is expected to continue its upward trajectory, driven by the increasing demand for high-performance electronic devices and the need for reliable packaging solutions.

| Report Metric | Details |

| Report Name | FC Underfills Market |

| Accounted market size in year | US$ 168 million |

| Forecasted market size in 2031 | US$ 303 million |

| CAGR | 8.9% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Henkel, NAMICS, LORD Corporation, Panacol, Won Chemical, Showa Denko, Shin-Etsu Chemical, AIM Solder, Zymet, Master Bond, Bondline |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |