What is Global Electrochemical Phosphine Sensor Market?

The Global Electrochemical Phosphine Sensor Market is a specialized segment within the broader sensor industry, focusing on devices that detect phosphine gas using electrochemical methods. Phosphine is a highly toxic and flammable gas, often used in various industrial applications, including fumigation and semiconductor manufacturing. The sensors are crucial for ensuring safety and compliance with environmental regulations, as they provide real-time monitoring of phosphine levels in the air. These sensors work by measuring the change in electrical current as phosphine gas interacts with a chemical solution within the sensor, allowing for accurate detection even at low concentrations. The market for these sensors is driven by increasing safety standards and the need for precise monitoring in industries that handle phosphine gas. As industries continue to prioritize safety and environmental responsibility, the demand for reliable and efficient phosphine sensors is expected to grow. The market is characterized by technological advancements, with manufacturers focusing on improving sensor sensitivity, response time, and durability. Overall, the Global Electrochemical Phosphine Sensor Market plays a vital role in safeguarding human health and the environment by providing essential tools for gas detection and monitoring.

Wall-Mounted, Pipe-Mounted in the Global Electrochemical Phosphine Sensor Market:

In the Global Electrochemical Phosphine Sensor Market, wall-mounted and pipe-mounted sensors are two prevalent types of installations, each serving distinct purposes and environments. Wall-mounted sensors are typically installed in fixed locations, such as industrial facilities, laboratories, or storage areas, where continuous monitoring of phosphine gas is essential. These sensors are designed to be easily accessible for maintenance and calibration, ensuring consistent performance over time. Wall-mounted sensors are often used in areas where phosphine gas is likely to accumulate, providing an early warning system to prevent potential hazards. They are equipped with features like digital displays, alarm systems, and connectivity options for integration with building management systems, enhancing their functionality and ease of use. On the other hand, pipe-mounted sensors are specifically designed for monitoring phosphine gas within pipelines or ductwork. These sensors are crucial in applications where phosphine gas is transported or used as part of a process, such as in chemical manufacturing or fumigation systems. Pipe-mounted sensors are engineered to withstand harsh conditions, including high pressure and temperature variations, ensuring accurate detection even in challenging environments. They are often equipped with robust housings and advanced sensing technologies to provide reliable performance in demanding applications. The choice between wall-mounted and pipe-mounted sensors depends on the specific requirements of the application, including the location of potential phosphine gas leaks, the need for continuous monitoring, and the environmental conditions. Both types of sensors play a critical role in ensuring safety and compliance with regulatory standards, helping industries manage the risks associated with phosphine gas exposure. As the demand for effective gas detection solutions continues to grow, manufacturers are focusing on developing innovative sensor technologies that offer enhanced performance, reliability, and ease of use. This includes advancements in sensor materials, signal processing algorithms, and connectivity options, enabling seamless integration with modern industrial systems. Overall, wall-mounted and pipe-mounted sensors are essential components of the Global Electrochemical Phosphine Sensor Market, providing versatile solutions for a wide range of applications and environments.

Petrochemical Industry, Semiconductor Manufacturing, Agricultural Production, Others in the Global Electrochemical Phosphine Sensor Market:

The Global Electrochemical Phosphine Sensor Market finds extensive usage across various industries, including the petrochemical industry, semiconductor manufacturing, agricultural production, and others. In the petrochemical industry, phosphine sensors are crucial for monitoring gas levels in refineries and chemical plants, where phosphine is often used as a catalyst or byproduct. These sensors help ensure the safety of workers and prevent environmental contamination by providing real-time data on phosphine concentrations. In semiconductor manufacturing, phosphine is used as a dopant in the production of semiconductors, making accurate monitoring essential to maintain product quality and safety. Electrochemical phosphine sensors are employed to detect any leaks or emissions, ensuring compliance with stringent industry standards and protecting sensitive equipment from damage. In agricultural production, phosphine is commonly used as a fumigant to control pests in stored grains and other agricultural products. Sensors are used to monitor phosphine levels during fumigation processes, ensuring effective pest control while minimizing risks to workers and the environment. Additionally, these sensors help optimize fumigation procedures by providing precise data on gas concentrations, leading to more efficient use of phosphine and reduced costs. Beyond these industries, electrochemical phosphine sensors are also used in various other applications, such as environmental monitoring, research laboratories, and emergency response situations. In environmental monitoring, sensors are deployed to track phosphine emissions from industrial sources, helping regulatory agencies enforce air quality standards and protect public health. In research laboratories, sensors are used to study the properties and behavior of phosphine gas, contributing to the development of new technologies and applications. In emergency response situations, portable phosphine sensors are used by first responders to assess gas levels and ensure the safety of affected areas. Overall, the Global Electrochemical Phosphine Sensor Market plays a vital role in enhancing safety, efficiency, and environmental responsibility across a wide range of industries and applications.

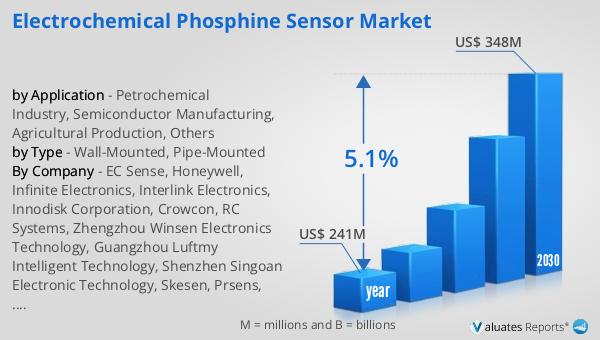

Global Electrochemical Phosphine Sensor Market Outlook:

The global market for Electrochemical Phosphine Sensors was valued at approximately $241 million in 2023, and it is anticipated to grow to a revised size of around $348 million by 2030. This growth trajectory represents a compound annual growth rate (CAGR) of 5.1% over the forecast period. The increasing demand for these sensors is driven by the need for enhanced safety measures and regulatory compliance across various industries that handle phosphine gas. As industries continue to prioritize safety and environmental responsibility, the adoption of advanced gas detection technologies is expected to rise. The market's growth is also supported by technological advancements in sensor design and functionality, which offer improved sensitivity, accuracy, and durability. Manufacturers are focusing on developing innovative solutions that cater to the specific needs of different applications, such as wall-mounted and pipe-mounted sensors for industrial and commercial use. Additionally, the growing awareness of the health and environmental risks associated with phosphine gas exposure is driving the demand for reliable and efficient monitoring solutions. As a result, the Global Electrochemical Phosphine Sensor Market is poised for steady growth, providing essential tools for gas detection and monitoring across a wide range of industries and applications.

| Report Metric | Details |

| Report Name | Electrochemical Phosphine Sensor Market |

| Accounted market size in year | US$ 241 million |

| Forecasted market size in 2030 | US$ 348 million |

| CAGR | 5.1% |

| Base Year | year |

| Forecasted years | 2025 - 2030 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | EC Sense, Honeywell, Infinite Electronics, Interlink Electronics, Innodisk Corporation, Crowcon, RC Systems, Zhengzhou Winsen Electronics Technology, Guangzhou Luftmy Intelligent Technology, Shenzhen Singoan Electronic Technology, Skesen, Prsens, Advanced Sensors Application, Sangbay |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |