What is Global CNC Lathes Market?

The Global CNC Lathes Market refers to the worldwide industry focused on the production, distribution, and utilization of CNC (Computer Numerical Control) lathes. These machines are pivotal in the manufacturing sector, as they automate the process of cutting, sanding, knurling, drilling, or deforming materials to create precise components. CNC lathes are highly valued for their ability to produce complex parts with high precision and repeatability, which is essential in industries such as automotive, aerospace, electronics, and more. The market encompasses a wide range of CNC lathe types, including vertical and horizontal configurations, each offering unique advantages depending on the application. The growth of this market is driven by the increasing demand for high-quality, precision-engineered components, advancements in automation technology, and the need for efficient production processes. As industries continue to evolve and require more sophisticated machinery, the Global CNC Lathes Market is expected to expand, offering new opportunities for manufacturers and suppliers worldwide. This market is characterized by continuous innovation, with companies investing in research and development to enhance the capabilities and efficiency of CNC lathes, thereby meeting the ever-changing demands of modern manufacturing.

Vertical, Horizontal in the Global CNC Lathes Market:

In the Global CNC Lathes Market, vertical and horizontal CNC lathes play crucial roles, each serving specific needs based on their design and functionality. Vertical CNC lathes are characterized by their vertical spindle orientation, which allows for the workpiece to be mounted on a horizontal table. This configuration is particularly advantageous for machining large, heavy, or awkwardly shaped parts, as the gravitational force helps stabilize the workpiece during the machining process. Vertical lathes are often used in industries where large diameter components are required, such as in the production of wheels, large bearings, and aerospace components. The vertical design also facilitates easier loading and unloading of heavy parts, making it a preferred choice for certain applications. On the other hand, horizontal CNC lathes have a spindle that is horizontally oriented, which is ideal for long workpieces that require support along their length. This type of lathe is commonly used for producing cylindrical parts, such as shafts, rods, and tubes, which are prevalent in automotive and mechanical industries. Horizontal lathes offer the advantage of better chip removal due to gravity, which can enhance the machining process's efficiency and precision. Additionally, horizontal lathes are often more versatile, allowing for a wider range of operations, including turning, threading, and drilling. Both vertical and horizontal CNC lathes are integral to the Global CNC Lathes Market, with manufacturers continually innovating to improve their capabilities. The choice between vertical and horizontal lathes depends largely on the specific requirements of the task at hand, including the size, shape, and material of the workpiece, as well as the desired precision and production volume. As technology advances, both types of lathes are being equipped with enhanced features such as multi-axis capabilities, improved control systems, and automation options, further expanding their applications across various industries. The ongoing development in CNC technology ensures that both vertical and horizontal lathes remain vital tools in modern manufacturing, catering to the diverse needs of industries worldwide.

Automotive, Optical, Medical and Biotechnology, Mechanical, Electronics, Aerospace & Defense, Others in the Global CNC Lathes Market:

The Global CNC Lathes Market finds extensive applications across various industries, each benefiting from the precision and efficiency these machines offer. In the automotive sector, CNC lathes are indispensable for manufacturing engine components, transmission parts, and other critical elements that require high precision and durability. The ability to produce complex geometries with tight tolerances makes CNC lathes ideal for automotive applications, where performance and reliability are paramount. In the optical industry, CNC lathes are used to create lenses and other optical components with exceptional accuracy, ensuring optimal performance in devices such as cameras, microscopes, and telescopes. The medical and biotechnology fields also rely heavily on CNC lathes for producing surgical instruments, implants, and prosthetics, where precision and biocompatibility are crucial. These machines enable the production of intricate designs that meet stringent medical standards, contributing to advancements in healthcare technology. In the mechanical industry, CNC lathes are employed to manufacture a wide range of components, from simple fasteners to complex machinery parts, supporting the production of equipment used in construction, agriculture, and other sectors. The electronics industry benefits from CNC lathes in the production of components such as connectors, housings, and heat sinks, which require precise machining to ensure proper functionality and performance. Aerospace and defense sectors utilize CNC lathes for producing critical components such as turbine blades, structural parts, and missile components, where precision and reliability are essential for safety and performance. The versatility of CNC lathes allows them to cater to the diverse needs of these industries, providing solutions that enhance productivity and quality. Additionally, CNC lathes are used in various other sectors, including energy, marine, and consumer goods, where they contribute to the efficient production of high-quality components. The widespread adoption of CNC lathes across these industries underscores their importance in modern manufacturing, driving innovation and growth in the Global CNC Lathes Market.

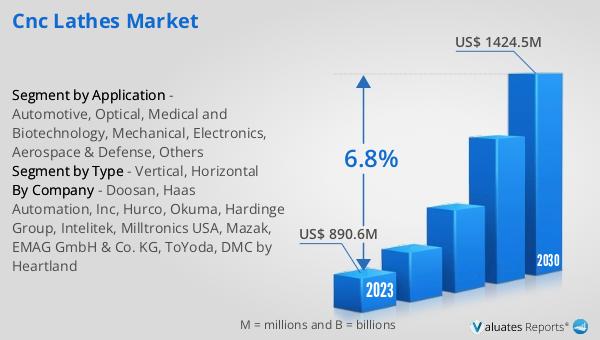

Global CNC Lathes Market Outlook:

The outlook for the Global CNC Lathes Market indicates a promising growth trajectory, with the market expected to expand from a valuation of approximately $959.9 million in 2024 to around $1,424.5 million by 2030. This growth is projected to occur at a compound annual growth rate (CAGR) of 6.8% over the forecast period. This upward trend reflects the increasing demand for CNC lathes across various industries, driven by the need for precision-engineered components and efficient manufacturing processes. The automotive, aerospace, electronics, and medical sectors, among others, are continually seeking advanced machinery to enhance their production capabilities, contributing to the market's expansion. The adoption of automation and digitalization in manufacturing processes further fuels the demand for CNC lathes, as companies strive to improve productivity and reduce operational costs. Additionally, the ongoing advancements in CNC technology, such as the integration of artificial intelligence and machine learning, are expected to enhance the functionality and efficiency of CNC lathes, making them more attractive to manufacturers. As industries continue to evolve and require more sophisticated machinery, the Global CNC Lathes Market is poised for significant growth, offering new opportunities for manufacturers and suppliers worldwide. This positive market outlook underscores the importance of CNC lathes in modern manufacturing, highlighting their role in driving innovation and efficiency across various sectors.

| Report Metric | Details |

| Report Name | CNC Lathes Market |

| Accounted market size in 2024 | US$ 959.9 million |

| Forecasted market size in 2030 | US$ 1424.5 million |

| CAGR | 6.8 |

| Base Year | 2024 |

| Forecasted years | 2025 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | Doosan, Haas Automation, Inc, Hurco, Okuma, Hardinge Group, Intelitek, Milltronics USA, Mazak, EMAG GmbH & Co. KG, ToYoda, DMC by Heartland |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |