What is Global Cable Recycling Separator Machines Market?

The Global Cable Recycling Separator Machines Market is a specialized segment within the recycling industry that focuses on the recovery and separation of valuable materials from discarded cables. These machines are designed to efficiently process various types of cables, including copper, aluminum, and fiber optic cables, to extract metals and other reusable components. The market is driven by the increasing demand for sustainable practices and the need to reduce electronic waste. As industries and consumers become more environmentally conscious, the recycling of cables has gained significant importance. These machines not only help in reducing the environmental impact of cable waste but also contribute to the circular economy by providing raw materials for new products. The market encompasses a range of technologies and equipment, from simple manual separators to advanced automated systems, catering to different scales of operation. With the growing emphasis on resource conservation and waste management, the Global Cable Recycling Separator Machines Market is poised for continued growth, offering innovative solutions for efficient cable recycling.

More Than 300 T/h, 200 T/h - 299 T/h, Less Than 200 T/h in the Global Cable Recycling Separator Machines Market:

In the Global Cable Recycling Separator Machines Market, the capacity of machines is often categorized based on their throughput, which refers to the amount of material they can process per hour. This categorization helps in understanding the scale and efficiency of different machines available in the market. Machines with a capacity of More Than 300 T/h are designed for large-scale operations, typically used by major recycling facilities that handle vast quantities of cable waste. These high-capacity machines are equipped with advanced technologies to ensure efficient separation and recovery of materials, making them ideal for industries with substantial recycling needs. They are often automated and require minimal human intervention, which enhances their operational efficiency and reduces labor costs. On the other hand, machines with a capacity of 200 T/h - 299 T/h serve medium-sized operations. These machines strike a balance between capacity and cost, making them suitable for businesses that need to process a significant amount of cable waste but do not require the extensive capabilities of the largest machines. They offer a good mix of efficiency and affordability, catering to a wide range of industries. Lastly, machines with a capacity of Less Than 200 T/h are designed for smaller operations or niche markets. These machines are often more compact and cost-effective, making them accessible to smaller businesses or startups in the recycling industry. They are ideal for companies that are just beginning to explore cable recycling or those that operate in regions with limited cable waste. Despite their smaller size, these machines are capable of delivering efficient separation and recovery of materials, ensuring that even small-scale operations can contribute to sustainable recycling practices. Each category of machine plays a crucial role in the Global Cable Recycling Separator Machines Market, providing solutions tailored to the specific needs and capacities of different businesses. As the demand for cable recycling continues to grow, these machines will remain essential tools in the effort to reduce electronic waste and promote resource conservation.

Automotive, Industrial Machinery, Shipbuilding, Building and Construction, Electrical and Electronics, Consumer Appliances, Others in the Global Cable Recycling Separator Machines Market:

The Global Cable Recycling Separator Machines Market finds its applications across various industries, each with unique requirements and benefits from cable recycling. In the automotive industry, these machines are crucial for recycling the extensive wiring systems used in vehicles. As cars become more technologically advanced, the amount of wiring increases, leading to a higher volume of cable waste. Recycling these cables not only helps in recovering valuable metals like copper and aluminum but also reduces the environmental impact of automotive waste. In the industrial machinery sector, cable recycling machines are used to process the wiring and cables from old or obsolete machinery. This helps in reclaiming valuable materials and reducing the need for new raw materials, contributing to cost savings and sustainability. The shipbuilding industry also benefits from cable recycling, as ships contain extensive wiring systems that need to be replaced or disposed of during maintenance or decommissioning. Recycling these cables helps in managing waste effectively and recovering valuable resources. In the building and construction industry, cable recycling machines are used to process the wiring from demolished buildings or renovation projects. This not only helps in reducing construction waste but also provides materials for new projects. The electrical and electronics industry is another major user of cable recycling machines, as it generates a significant amount of cable waste from manufacturing processes and end-of-life products. Recycling these cables helps in recovering precious metals and reducing the environmental impact of electronic waste. Consumer appliances, such as refrigerators, washing machines, and televisions, also contain a considerable amount of wiring that can be recycled. Cable recycling machines help in processing these appliances, ensuring that valuable materials are recovered and waste is minimized. Other industries, such as telecommunications and renewable energy, also utilize cable recycling machines to manage their cable waste efficiently. Overall, the Global Cable Recycling Separator Machines Market plays a vital role in promoting sustainability and resource conservation across various sectors, helping industries manage their waste effectively and contribute to a circular economy.

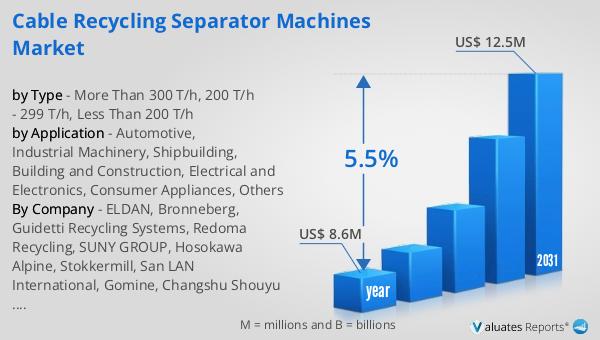

Global Cable Recycling Separator Machines Market Outlook:

The global market for Cable Recycling Separator Machines was valued at $8.6 million in 2024 and is expected to grow significantly over the coming years. By 2031, it is projected to reach a revised size of $12.5 million, reflecting a compound annual growth rate (CAGR) of 5.5% during the forecast period. This growth can be attributed to several factors, including the increasing awareness of environmental issues and the need for sustainable waste management solutions. As industries and consumers become more conscious of their environmental impact, the demand for efficient recycling technologies, such as cable recycling separator machines, is expected to rise. These machines offer a practical solution for managing cable waste, recovering valuable materials, and reducing the environmental footprint of various industries. The projected growth in the market also highlights the increasing adoption of these machines across different sectors, as businesses recognize the economic and environmental benefits of cable recycling. With advancements in technology and the development of more efficient and cost-effective machines, the Global Cable Recycling Separator Machines Market is poised for continued expansion, offering innovative solutions for sustainable waste management.

| Report Metric | Details |

| Report Name | Cable Recycling Separator Machines Market |

| Accounted market size in year | US$ 8.6 million |

| Forecasted market size in 2031 | US$ 12.5 million |

| CAGR | 5.5% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | ELDAN, Bronneberg, Guidetti Recycling Systems, Redoma Recycling, SUNY GROUP, Hosokawa Alpine, Stokkermill, San LAN International, Gomine, Changshu Shouyu Machinery, Jiangsu Jingliang New Energy, Zhangjiagang Tairong Machinery |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |