What is Global Brass Electrode Wire Market?

The Global Brass Electrode Wire Market is a specialized segment within the broader electrode wire industry, focusing on the production and distribution of brass electrode wires. These wires are primarily used in electrical discharge machining (EDM), a process that relies on electrical discharges to shape materials. Brass electrode wires are favored for their excellent conductivity, corrosion resistance, and mechanical strength, making them ideal for precision machining tasks. The market encompasses a wide range of applications, including automotive, aerospace, electronics, and medical device manufacturing. As industries continue to demand high-precision components, the need for reliable and efficient electrode wires has grown, driving the expansion of this market. The global reach of the market is supported by advancements in manufacturing technologies and the increasing adoption of EDM processes across various sectors. This growth is further fueled by the rising demand for miniaturized components and complex geometries, which require the precision and efficiency that brass electrode wires provide. As a result, the Global Brass Electrode Wire Market is poised for significant growth, driven by technological innovations and the expanding needs of modern manufacturing industries.

in the Global Brass Electrode Wire Market:

In the Global Brass Electrode Wire Market, various types of brass electrode wires are utilized by different customers, each catering to specific needs and applications. One of the most common types is the plain brass electrode wire, which is widely used due to its excellent electrical conductivity and cost-effectiveness. This type is often employed in general-purpose EDM applications where precision and efficiency are required. Another popular variant is the coated brass electrode wire, which features a thin layer of zinc or other materials to enhance its performance. The coating improves the wire's wear resistance and stability during the EDM process, making it suitable for more demanding applications. Customers in industries such as aerospace and automotive often prefer coated wires for their ability to produce high-quality finishes and intricate details. Additionally, there are high-performance brass electrode wires designed for specific applications that require exceptional precision and surface finish. These wires are typically used in the production of complex components with tight tolerances, such as those found in the medical device and electronics industries. The choice of wire type depends on several factors, including the material being machined, the desired surface finish, and the complexity of the component. For instance, in the aerospace industry, where components often have complex geometries and require high precision, coated or high-performance brass electrode wires are preferred. These wires provide the necessary accuracy and surface finish, ensuring that the components meet stringent industry standards. Similarly, in the automotive sector, where efficiency and cost-effectiveness are crucial, plain brass electrode wires are often used for general machining tasks. However, for more intricate parts, such as engine components or transmission parts, coated wires may be employed to achieve the required precision and durability. In the electronics industry, where miniaturization and precision are paramount, high-performance brass electrode wires are commonly used. These wires enable the production of small, intricate components with high accuracy, ensuring that they function correctly in electronic devices. The medical device industry also relies on high-performance wires for the production of components such as surgical instruments and implants, where precision and biocompatibility are critical. Overall, the Global Brass Electrode Wire Market offers a diverse range of wire types to meet the varying needs of different industries. Customers can choose from plain, coated, or high-performance wires based on their specific requirements, ensuring that they achieve the desired results in their machining processes. As the demand for precision and efficiency continues to grow across various sectors, the market for brass electrode wires is expected to expand, driven by the increasing adoption of EDM technology and the need for high-quality components.

Mechanical Equipment, Mould, Other in the Global Brass Electrode Wire Market:

The usage of Global Brass Electrode Wire Market extends across several key areas, including mechanical equipment, mould making, and other specialized applications. In the realm of mechanical equipment, brass electrode wires are integral to the manufacturing process, particularly in the production of high-precision components. These wires are used in EDM machines to cut and shape metal parts with exceptional accuracy, ensuring that the components meet the stringent specifications required in industries such as aerospace, automotive, and heavy machinery. The ability of brass electrode wires to produce intricate details and smooth finishes makes them indispensable in the production of gears, shafts, and other critical mechanical components. In mould making, brass electrode wires play a crucial role in the creation of moulds used for casting and injection moulding processes. The precision and efficiency of EDM with brass wires allow for the production of complex mould geometries with high accuracy, ensuring that the final products meet the desired specifications. This is particularly important in industries such as plastics, where the quality of the mould directly impacts the quality of the final product. Brass electrode wires enable manufacturers to produce moulds with intricate details and smooth surfaces, reducing the need for additional finishing processes and improving overall production efficiency. Beyond mechanical equipment and mould making, brass electrode wires find applications in various other areas, including the production of electronic components, medical devices, and precision instruments. In the electronics industry, the demand for miniaturized components with high precision has led to the widespread use of brass electrode wires in the production of circuit boards, connectors, and other electronic parts. The ability of these wires to produce small, intricate components with high accuracy ensures that electronic devices function correctly and reliably. In the medical device industry, brass electrode wires are used in the production of surgical instruments, implants, and other critical components. The precision and biocompatibility of these wires make them ideal for producing components that meet the stringent requirements of the medical field. Additionally, brass electrode wires are used in the production of precision instruments, such as measuring devices and sensors, where accuracy and reliability are paramount. Overall, the Global Brass Electrode Wire Market serves a wide range of industries, providing the precision and efficiency needed to produce high-quality components. As the demand for precision and miniaturization continues to grow, the market for brass electrode wires is expected to expand, driven by the increasing adoption of EDM technology and the need for high-quality components across various sectors.

Global Brass Electrode Wire Market Outlook:

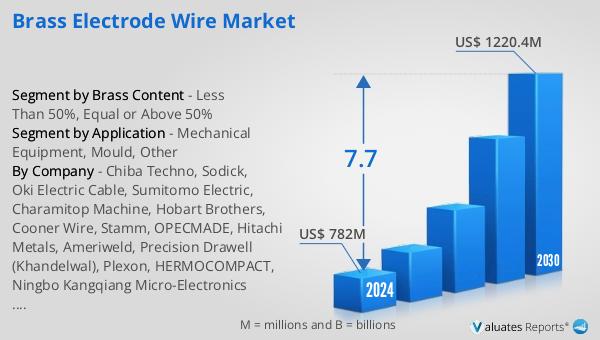

The outlook for the Global Brass Electrode Wire Market indicates a promising growth trajectory. The market is anticipated to expand from a valuation of US$ 782 million in 2024 to an impressive US$ 1220.4 million by 2030. This growth is expected to occur at a Compound Annual Growth Rate (CAGR) of 7.7% over the forecast period. This upward trend is driven by several factors, including the increasing demand for precision machining and the widespread adoption of EDM technology across various industries. As manufacturers continue to seek high-quality components with intricate details and smooth finishes, the demand for brass electrode wires is set to rise. The market's growth is also supported by advancements in manufacturing technologies, which have enhanced the performance and efficiency of brass electrode wires. These innovations have made it possible to produce wires with improved conductivity, wear resistance, and stability, meeting the evolving needs of modern manufacturing processes. Additionally, the expanding applications of brass electrode wires in industries such as aerospace, automotive, electronics, and medical devices further contribute to the market's growth. As these industries continue to evolve and demand more complex and precise components, the need for reliable and efficient electrode wires will only increase. Overall, the Global Brass Electrode Wire Market is poised for significant growth, driven by technological advancements and the expanding needs of various industries.

| Report Metric | Details |

| Report Name | Brass Electrode Wire Market |

| Accounted market size in 2024 | US$ 782 in million |

| Forecasted market size in 2030 | US$ 1220.4 million |

| CAGR | 7.7 |

| Base Year | 2024 |

| Forecasted years | 2025 - 2030 |

| Segment by Brass Content |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | Chiba Techno, Sodick, Oki Electric Cable, Sumitomo Electric, Charamitop Machine, Hobart Brothers, Cooner Wire, Stamm, OPECMADE, Hitachi Metals, Ameriweld, Precision Drawell (Khandelwal), Plexon, HERMOCOMPACT, Ningbo Kangqiang Micro-Electronics Technology, Ningbo Bode Hightech, Kunshan Hengshitong Metal Products |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |