What is Global Beryllium-Copper Alloys Market?

The global Beryllium-Copper Alloys market is a specialized segment within the broader metal alloys industry, characterized by its unique properties and diverse applications. Beryllium-copper alloys are known for their exceptional strength, conductivity, and resistance to corrosion, making them highly valuable in various industrial applications. These alloys are composed primarily of copper, with a small percentage of beryllium, which significantly enhances their mechanical and thermal properties. The market for these alloys is driven by their demand in sectors such as electronics, aerospace, automotive, and oil and gas, where their superior performance is crucial. The global market is witnessing steady growth due to the increasing need for materials that can withstand extreme conditions while maintaining high performance. Additionally, advancements in manufacturing technologies and the development of new applications are further propelling the market forward. As industries continue to seek materials that offer a combination of strength, durability, and conductivity, the demand for beryllium-copper alloys is expected to rise, making it a key area of focus for manufacturers and researchers alike.

Rod, Bar, Wire, Tube, Others in the Global Beryllium-Copper Alloys Market:

In the global Beryllium-Copper Alloys market, products are categorized into various forms such as rods, bars, wires, tubes, and others, each serving distinct purposes across different industries. Rods, for instance, are cylindrical pieces of beryllium-copper alloy that are often used in applications requiring high strength and conductivity. They are commonly utilized in the manufacturing of components for electrical connectors, switches, and various mechanical parts. Bars, on the other hand, are similar to rods but are typically larger and used in applications where more substantial material is needed, such as in the construction of heavy-duty machinery and equipment. Wires made from beryllium-copper alloys are prized for their excellent conductivity and flexibility, making them ideal for use in electrical wiring, telecommunications, and electronic devices. These wires are often used in environments where reliability and performance are critical, such as in aerospace and defense applications. Tubes, which are hollow cylindrical forms of the alloy, are used in applications that require the passage of fluids or gases, such as in heat exchangers and hydraulic systems. The unique properties of beryllium-copper alloy tubes, including their resistance to corrosion and high thermal conductivity, make them suitable for use in harsh environments. Other forms of beryllium-copper alloys include sheets, plates, and forgings, which are used in a variety of applications ranging from aerospace components to industrial tooling. Each form of beryllium-copper alloy is designed to meet specific requirements, and the choice of form depends on the intended application and the performance characteristics needed. The versatility of these alloys, combined with their superior properties, makes them indispensable in many industries, driving the demand for these products in the global market.

Plastic Molds & Tooling, Electronic Springs & Connectors, Oil & Gas Equipment Components in the Global Beryllium-Copper Alloys Market:

The usage of beryllium-copper alloys in various industries highlights their versatility and importance. In the realm of plastic molds and tooling, these alloys are highly valued for their ability to withstand high temperatures and pressures, which are common in the molding process. The excellent thermal conductivity of beryllium-copper alloys ensures rapid and uniform heat distribution, reducing cycle times and improving the quality of molded products. This makes them an ideal choice for manufacturers looking to enhance productivity and product quality. In the electronics industry, beryllium-copper alloys are extensively used in the production of springs and connectors. Their high electrical conductivity and strength make them perfect for applications where reliable electrical connections are crucial. These alloys are often used in connectors for computers, smartphones, and other electronic devices, where they provide consistent performance and durability. Additionally, the corrosion resistance of beryllium-copper alloys ensures that electronic components remain reliable over time, even in challenging environments. In the oil and gas sector, beryllium-copper alloys are used in the manufacture of equipment components that must endure harsh conditions. Their resistance to corrosion and wear makes them suitable for use in drilling tools, valves, and other critical components that operate in extreme environments. The ability of these alloys to maintain their mechanical properties under high stress and temperature conditions is essential for ensuring the reliability and safety of oil and gas operations. Overall, the unique properties of beryllium-copper alloys make them indispensable in these industries, where performance, reliability, and durability are paramount.

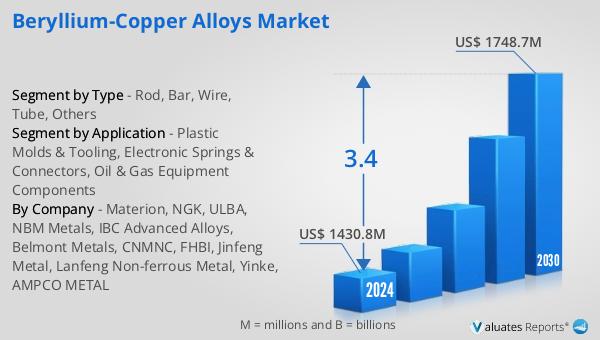

Global Beryllium-Copper Alloys Market Outlook:

The outlook for the global Beryllium-Copper Alloys market indicates a steady growth trajectory, with projections suggesting an increase from $1,430.8 million in 2024 to $1,748.7 million by 2030. This growth is expected to occur at a compound annual growth rate (CAGR) of 3.4% during the forecast period. The market is dominated by key players such as Materion, NGK, Kazatomprom, CUMNC, Aviva Metals, and Belmont Metals, which collectively account for approximately 75% of the market share. North America emerges as the largest market for beryllium-copper alloys, holding a significant share of about 57%. This dominance can be attributed to the region's advanced industrial base, technological advancements, and the presence of major manufacturers. The demand for beryllium-copper alloys in North America is driven by their extensive use in industries such as electronics, aerospace, and automotive, where their superior properties are highly valued. As the market continues to grow, manufacturers are likely to focus on expanding their product offerings and enhancing their production capabilities to meet the increasing demand. The global Beryllium-Copper Alloys market presents significant opportunities for growth, driven by the need for high-performance materials across various industries.

| Report Metric | Details |

| Report Name | Beryllium-Copper Alloys Market |

| Accounted market size in 2024 | US$ 1430.8 in million |

| Forecasted market size in 2030 | US$ 1748.7 million |

| CAGR | 3.4 |

| Base Year | 2024 |

| Forecasted years | 2025 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | Materion, NGK, ULBA, NBM Metals, IBC Advanced Alloys, Belmont Metals, CNMNC, FHBI, Jinfeng Metal, Lanfeng Non-ferrous Metal, Yinke, AMPCO METAL |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |