What is Global Ball Screws for Machine Tools Market?

The Global Ball Screws for Machine Tools Market is a specialized segment within the broader machine tools industry, focusing on the production and distribution of ball screws. These components are essential for converting rotational motion into linear motion with high precision and efficiency, making them indispensable in various industrial applications. Ball screws are widely used in CNC machines, robotics, and other automated systems due to their ability to provide smooth and accurate movement. The market for ball screws is driven by the increasing demand for high-precision machining and automation in industries such as automotive, aerospace, and electronics. As manufacturing processes become more sophisticated, the need for reliable and efficient motion control components like ball screws continues to grow. This market is characterized by technological advancements, with manufacturers constantly innovating to improve the performance and durability of ball screws. Additionally, the global nature of the market means that it is influenced by economic conditions, trade policies, and technological trends across different regions. Overall, the Global Ball Screws for Machine Tools Market plays a crucial role in supporting the advancement of modern manufacturing technologies.

Internal Circulation Ballscrew, External Circulation Ballscrew in the Global Ball Screws for Machine Tools Market:

Internal Circulation Ballscrews and External Circulation Ballscrews are two primary types of ball screws used in the Global Ball Screws for Machine Tools Market, each with distinct characteristics and applications. Internal Circulation Ballscrews are designed with a recirculation system that is integrated within the nut, allowing the balls to circulate internally. This design offers several advantages, including a more compact structure, reduced noise, and improved efficiency due to the shorter circulation path. Internal Circulation Ballscrews are particularly suitable for applications where space is limited, and high precision is required, such as in compact CNC machines and precision instruments. On the other hand, External Circulation Ballscrews feature a recirculation system that is external to the nut, with the balls traveling through a return tube or channel. This design allows for larger load capacities and is often used in heavy-duty applications where robustness and durability are critical. External Circulation Ballscrews are commonly found in large industrial machinery, heavy-duty CNC machines, and applications requiring high load-bearing capabilities. Both types of ballscrews are essential in the machine tools market, offering unique benefits that cater to different industrial needs. The choice between internal and external circulation ballscrews depends on factors such as load requirements, space constraints, and the specific application. Manufacturers in the Global Ball Screws for Machine Tools Market continue to innovate and improve these products, focusing on enhancing performance, reliability, and cost-effectiveness. As industries increasingly adopt automation and precision machining, the demand for both internal and external circulation ballscrews is expected to rise, driving further advancements in this market segment.

Machinery Manufacturing, Automobile, Aerospace & Defense, Others in the Global Ball Screws for Machine Tools Market:

The usage of Global Ball Screws for Machine Tools Market spans several key areas, including Machinery Manufacturing, Automobile, Aerospace & Defense, and others, each benefiting from the precision and efficiency offered by ball screws. In Machinery Manufacturing, ball screws are integral components in CNC machines, lathes, and milling machines, providing the precise linear motion required for accurate machining operations. Their ability to convert rotational motion into linear motion with minimal friction makes them ideal for high-precision manufacturing processes, enhancing productivity and product quality. In the Automobile industry, ball screws are used in various applications, such as in the production of automotive components and assembly lines. They enable precise control of movement in robotic arms and automated systems, contributing to the efficiency and accuracy of manufacturing processes. In the Aerospace & Defense sector, the demand for high-precision components is critical, and ball screws play a vital role in applications such as aircraft assembly, missile guidance systems, and satellite positioning. Their reliability and precision are crucial in ensuring the safety and performance of aerospace and defense equipment. Beyond these industries, ball screws are also used in other areas such as medical equipment, electronics manufacturing, and renewable energy systems. In medical equipment, for example, ball screws are used in imaging devices and surgical robots, where precision and smooth operation are essential. In electronics manufacturing, they are used in the production of semiconductors and circuit boards, where accuracy and repeatability are critical. In renewable energy systems, ball screws are used in solar tracking systems and wind turbine pitch control, where precise positioning is necessary for optimal performance. Overall, the versatility and precision of ball screws make them indispensable in a wide range of industries, driving their demand in the Global Ball Screws for Machine Tools Market.

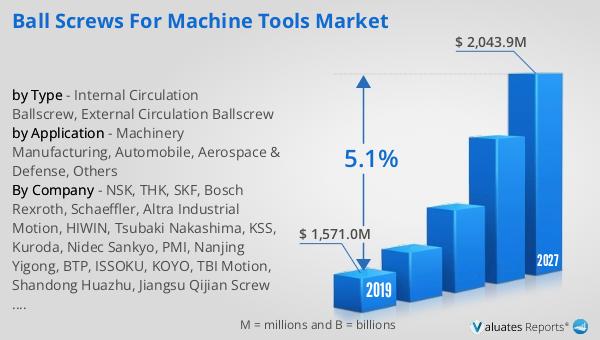

Global Ball Screws for Machine Tools Market Outlook:

The global precision ball screw market was valued at $1,571 million in 2019, and it is anticipated to grow significantly, reaching approximately $2,043.9 million by 2027. This growth trajectory represents a compound annual growth rate (CAGR) of 5.1%. The increasing demand for precision and efficiency in various industrial applications is a key driver of this market expansion. As industries continue to adopt advanced manufacturing technologies and automation, the need for reliable and high-performance motion control components like precision ball screws is expected to rise. The market's growth is also supported by technological advancements, with manufacturers focusing on developing innovative solutions to enhance the performance and durability of ball screws. Additionally, the global nature of the market means that it is influenced by economic conditions, trade policies, and technological trends across different regions. As a result, the precision ball screw market is poised for steady growth, driven by the increasing demand for high-precision machining and automation in industries such as automotive, aerospace, and electronics. This market outlook highlights the importance of precision ball screws in supporting the advancement of modern manufacturing technologies and their role in driving industrial growth.

| Report Metric | Details |

| Report Name | Ball Screws for Machine Tools Market |

| Accounted market size in 2019 | $ 1,571.0 in million |

| Forecasted market size in 2027 | $ 2,043.9 million |

| CAGR | 5.1% |

| Base Year | 2019 |

| Forecasted years | 2025 - 2027 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | NSK, THK, SKF, Bosch Rexroth, Schaeffler, Altra Industrial Motion, HIWIN, Tsubaki Nakashima, KSS, Kuroda, Nidec Sankyo, PMI, Nanjing Yigong, BTP, ISSOKU, KOYO, TBI Motion, Shandong Huazhu, Jiangsu Qijian Screw Rod, SBC, Qidong Haosen, TRCD, Hanjiang Machine Tool, OZAK, Donglai Company |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |