What is Global Automatic Electrolytic Capacitor Winding Machine Market?

The Global Automatic Electrolytic Capacitor Winding Machine Market refers to the industry focused on the production and sale of machines designed to wind electrolytic capacitors automatically. These machines are crucial in the manufacturing process of electrolytic capacitors, which are essential components in various electronic devices. Electrolytic capacitors are used to store energy and are found in a wide range of applications, from consumer electronics to industrial machinery. The market for these winding machines is driven by the increasing demand for electronic devices and the need for efficient and precise manufacturing processes. As technology advances, the demand for more compact and efficient capacitors grows, pushing manufacturers to adopt automatic winding machines that offer higher precision and speed compared to manual methods. This market is characterized by technological innovations, with manufacturers continuously improving machine capabilities to meet the evolving needs of the electronics industry. The growth of this market is also influenced by the expansion of the electronics sector globally, particularly in regions with high technological adoption rates. Overall, the Global Automatic Electrolytic Capacitor Winding Machine Market plays a vital role in supporting the electronics manufacturing industry by providing the necessary equipment to produce high-quality capacitors efficiently.

Automatic Winding Machine, Semi-automatic Winding Machine in the Global Automatic Electrolytic Capacitor Winding Machine Market:

Automatic winding machines are sophisticated devices used in the production of electrolytic capacitors, designed to automate the winding process of the capacitor's internal components. These machines are equipped with advanced technology that allows for precise control over the winding process, ensuring consistency and quality in the final product. Automatic winding machines are typically used in large-scale manufacturing environments where high volumes of capacitors are produced. They offer several advantages over manual winding methods, including increased speed, accuracy, and the ability to handle complex winding patterns. These machines are often integrated with computer systems that allow for easy programming and monitoring of the winding process, enabling manufacturers to quickly adapt to different production requirements. On the other hand, semi-automatic winding machines combine elements of both manual and automatic processes. While they still require some level of human intervention, they offer greater flexibility and control compared to fully automatic machines. Semi-automatic machines are often used in smaller production settings or for specialized capacitor designs that require a more hands-on approach. They provide a cost-effective solution for manufacturers who need to produce a variety of capacitor types without investing in fully automated systems. In the Global Automatic Electrolytic Capacitor Winding Machine Market, both automatic and semi-automatic machines play crucial roles in meeting the diverse needs of capacitor manufacturers. The choice between these two types of machines depends on factors such as production volume, complexity of the capacitor design, and budget constraints. As the demand for electronic devices continues to grow, manufacturers are increasingly looking for ways to optimize their production processes, making the adoption of advanced winding machines a key focus area. The market for these machines is expected to expand as manufacturers seek to improve efficiency and reduce production costs while maintaining high-quality standards. Technological advancements in machine design and functionality are also driving the market, with manufacturers continuously developing new features to enhance the performance and versatility of winding machines. Overall, the Global Automatic Electrolytic Capacitor Winding Machine Market is characterized by a dynamic interplay between technological innovation and the evolving needs of the electronics industry, with both automatic and semi-automatic machines playing pivotal roles in shaping the future of capacitor manufacturing.

Mylar Film, Polypropylene Capacitor, Polystyrene Capacitor, Polycarbonate Capacitor in the Global Automatic Electrolytic Capacitor Winding Machine Market:

The Global Automatic Electrolytic Capacitor Winding Machine Market finds its application in the production of various types of capacitors, including Mylar Film, Polypropylene, Polystyrene, and Polycarbonate capacitors. Each of these capacitors has unique properties and applications, and the winding machines are tailored to meet the specific requirements of their production. Mylar Film capacitors, known for their stability and reliability, are widely used in applications requiring high precision and low loss. The automatic winding machines used in their production ensure that the thin Mylar film is wound with high accuracy, maintaining the capacitor's performance characteristics. Polypropylene capacitors, on the other hand, are valued for their excellent electrical properties and are commonly used in high-frequency applications. The winding machines for these capacitors are designed to handle the delicate polypropylene film, ensuring that it is wound tightly and uniformly to prevent any performance degradation. Polystyrene capacitors are known for their low dielectric absorption and are often used in audio and RF applications. The winding machines for these capacitors must be capable of handling the fragile polystyrene film with care, ensuring that it is wound without any damage or distortion. Finally, Polycarbonate capacitors are used in applications requiring high stability and low leakage. The winding machines for these capacitors are designed to accommodate the thicker polycarbonate film, ensuring that it is wound with precision and consistency. In each of these applications, the Global Automatic Electrolytic Capacitor Winding Machine Market plays a crucial role in ensuring that the capacitors are produced with the highest quality standards. The machines are equipped with advanced features that allow for precise control over the winding process, ensuring that the capacitors meet the specific performance requirements of their intended applications. As the demand for these capacitors continues to grow, manufacturers are increasingly relying on automatic winding machines to optimize their production processes and maintain a competitive edge in the market. The versatility and efficiency of these machines make them an indispensable tool in the production of high-quality capacitors, supporting the diverse needs of the electronics industry.

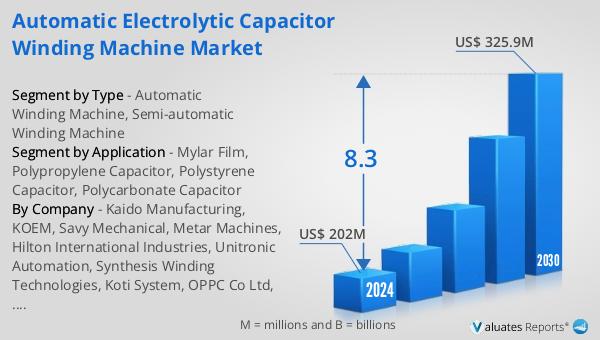

Global Automatic Electrolytic Capacitor Winding Machine Market Outlook:

The outlook for the Global Automatic Electrolytic Capacitor Winding Machine Market is promising, with projections indicating significant growth in the coming years. The market is expected to expand from a valuation of US$ 202 million in 2024 to approximately US$ 325.9 million by 2030. This growth trajectory represents a Compound Annual Growth Rate (CAGR) of 8.3% over the forecast period. Such robust growth can be attributed to several factors, including the increasing demand for electronic devices and the need for efficient manufacturing processes. As technology continues to advance, the demand for more compact and efficient capacitors is on the rise, driving manufacturers to invest in automatic winding machines that offer higher precision and speed. The market is also benefiting from technological innovations, with manufacturers continuously improving machine capabilities to meet the evolving needs of the electronics industry. Additionally, the expansion of the electronics sector globally, particularly in regions with high technological adoption rates, is further fueling the demand for these machines. The Global Automatic Electrolytic Capacitor Winding Machine Market is poised for significant growth, supported by the increasing adoption of advanced manufacturing technologies and the growing demand for high-quality capacitors. As manufacturers seek to optimize their production processes and reduce costs, the adoption of automatic winding machines is expected to become more widespread, driving further growth in the market. Overall, the market outlook is positive, with strong growth prospects and opportunities for innovation and development in the coming years.

| Report Metric | Details |

| Report Name | Automatic Electrolytic Capacitor Winding Machine Market |

| Accounted market size in 2024 | US$ 202 million |

| Forecasted market size in 2030 | US$ 325.9 million |

| CAGR | 8.3 |

| Base Year | 2024 |

| Forecasted years | 2025 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | Kaido Manufacturing, KOEM, Savy Mechanical, Metar Machines, Hilton International Industries, Unitronic Automation, Synthesis Winding Technologies, Koti System, OPPC Co Ltd, Jognic's, Heilongjiang Huaguan Science And Technology, Wuxi Lead Intelligent Equipment, Xingchengjie Precise Equipment |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |