What is Global Additives for Printing Inks Market?

The Global Additives for Printing Inks Market is a dynamic and evolving sector that plays a crucial role in the printing industry. Additives are essential components used in printing inks to enhance their performance, quality, and functionality. These additives can include a variety of substances such as dispersants, defoamers, wetting agents, and more, each serving a specific purpose to improve the ink's properties. The market for these additives is driven by the increasing demand for high-quality printing across various industries, including packaging, publishing, and advertising. As technology advances, the need for specialized inks that can deliver vibrant colors, quick drying times, and durability has grown, leading to a rise in the demand for additives. Additionally, environmental concerns and regulations have prompted the development of eco-friendly additives, further expanding the market. The global reach of this market is significant, with manufacturers and suppliers operating in various regions to meet the diverse needs of consumers. Overall, the Global Additives for Printing Inks Market is a vital component of the printing industry, contributing to the production of high-quality printed materials that meet the ever-evolving demands of consumers and businesses alike.

Organic Type, Inorganic Type in the Global Additives for Printing Inks Market:

In the realm of the Global Additives for Printing Inks Market, additives are broadly categorized into organic and inorganic types, each offering distinct benefits and applications. Organic additives are primarily derived from carbon-based compounds and are known for their versatility and compatibility with various ink formulations. These additives often include substances like surfactants, which help in reducing surface tension and improving the wetting properties of inks. Organic additives are particularly favored for their ability to enhance the color vibrancy and gloss of printed materials, making them ideal for applications where visual appeal is paramount. Additionally, they are often biodegradable and less harmful to the environment, aligning with the growing demand for sustainable printing solutions. On the other hand, inorganic additives are typically composed of mineral-based compounds and are valued for their durability and stability. These additives can include materials like silica, which is used to improve the abrasion resistance and mechanical strength of inks. Inorganic additives are often employed in applications where the printed material needs to withstand harsh conditions, such as outdoor signage or industrial labeling. They are also known for their ability to enhance the opacity and coverage of inks, ensuring that printed images and text remain clear and legible even on dark or colored substrates. The choice between organic and inorganic additives often depends on the specific requirements of the printing application, with factors such as cost, performance, and environmental impact playing a crucial role in decision-making. As the printing industry continues to evolve, the demand for both organic and inorganic additives is expected to grow, driven by the need for high-performance inks that can meet the diverse needs of consumers and businesses. Manufacturers are continually innovating to develop new additives that offer improved performance and sustainability, ensuring that the Global Additives for Printing Inks Market remains a dynamic and competitive sector. The interplay between organic and inorganic additives highlights the complexity and diversity of the market, with each type offering unique advantages that cater to different printing needs. As such, understanding the characteristics and applications of these additives is essential for stakeholders looking to capitalize on the opportunities within this market. Whether it's enhancing the aesthetic appeal of printed materials or ensuring their durability and functionality, additives play a crucial role in the success of the printing industry, making them an indispensable component of modern printing technology.

Solvent-borne Printing Inks, Solvent-free Printing Inks in the Global Additives for Printing Inks Market:

The Global Additives for Printing Inks Market finds extensive usage in both solvent-borne and solvent-free printing inks, each serving distinct purposes and applications. Solvent-borne printing inks are traditional inks that use organic solvents as a carrier for the pigments and additives. These inks are known for their fast drying times and excellent adhesion properties, making them suitable for high-speed printing processes and a wide range of substrates, including plastics, metals, and non-porous materials. Additives used in solvent-borne inks are designed to enhance these properties, ensuring that the inks deliver consistent performance and quality. For instance, dispersants are commonly used to stabilize the pigment particles, preventing them from settling and ensuring uniform color distribution. Defoamers are also added to minimize foam formation during the printing process, which can otherwise lead to defects in the printed material. On the other hand, solvent-free printing inks, also known as water-based or UV-curable inks, are gaining popularity due to their environmental benefits and reduced volatile organic compound (VOC) emissions. These inks use water or UV-curable resins as a carrier, making them a more sustainable option for printing applications. Additives for solvent-free inks are tailored to address the unique challenges associated with these formulations. For example, wetting agents are used to improve the flow and spread of the ink on the substrate, ensuring even coverage and reducing the risk of defects. Rheology modifiers are also important additives in solvent-free inks, as they help control the viscosity and flow properties of the ink, ensuring optimal performance during the printing process. The choice of additives for solvent-free inks is often influenced by the need to balance performance with environmental considerations, as manufacturers strive to develop inks that are both effective and eco-friendly. The growing demand for sustainable printing solutions has led to increased research and development in the field of solvent-free inks, with manufacturers exploring new additives and formulations that can deliver the desired performance without compromising on environmental impact. As the printing industry continues to evolve, the role of additives in both solvent-borne and solvent-free inks is becoming increasingly important, with manufacturers seeking to develop innovative solutions that meet the diverse needs of consumers and businesses. Whether it's enhancing the performance of traditional solvent-borne inks or developing new formulations for solvent-free inks, additives play a crucial role in the success of the Global Additives for Printing Inks Market, ensuring that printed materials meet the highest standards of quality and sustainability.

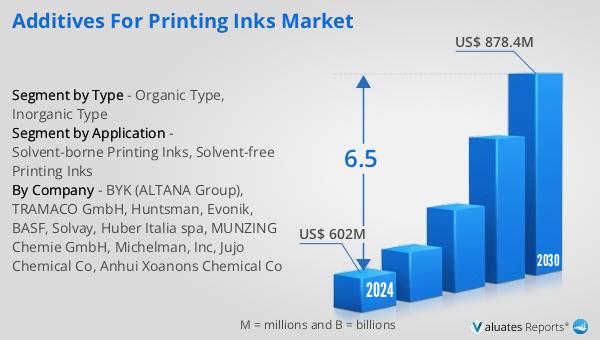

Global Additives for Printing Inks Market Outlook:

The outlook for the Global Additives for Printing Inks Market indicates a promising growth trajectory over the coming years. According to projections, the market is expected to expand from a valuation of $602 million in 2024 to approximately $878.4 million by 2030. This growth is anticipated to occur at a Compound Annual Growth Rate (CAGR) of 6.5% during the forecast period. This upward trend can be attributed to several factors, including the increasing demand for high-quality printing across various industries and the growing emphasis on sustainability and eco-friendly solutions. As businesses and consumers continue to seek out printed materials that are both visually appealing and environmentally responsible, the demand for specialized additives that can enhance the performance and sustainability of printing inks is expected to rise. Additionally, advancements in printing technology and the development of new ink formulations are likely to drive further innovation in the additives market, creating new opportunities for manufacturers and suppliers. The projected growth of the Global Additives for Printing Inks Market underscores the importance of these additives in the printing industry, highlighting their role in delivering high-quality, sustainable printing solutions that meet the evolving needs of consumers and businesses worldwide.

| Report Metric | Details |

| Report Name | Additives for Printing Inks Market |

| Accounted market size in 2024 | US$ 602 million |

| Forecasted market size in 2030 | US$ 878.4 million |

| CAGR | 6.5 |

| Base Year | 2024 |

| Forecasted years | 2025 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | BYK (ALTANA Group), TRAMACO GmbH, Huntsman, Evonik, BASF, Solvay, Huber Italia spa, MUNZING Chemie GmbH, Michelman, Inc, Jujo Chemical Co, Anhui Xoanons Chemical Co |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |