What is Electromagnetic Power Failure Brake - Global Market?

Electromagnetic power failure brakes are a crucial component in various industrial applications, designed to provide reliable stopping power in the event of a power loss. These brakes operate using electromagnetic force to engage and disengage the braking mechanism, ensuring safety and precision in machinery operations. The global market for these brakes is driven by their widespread use in industries that require fail-safe braking systems, such as manufacturing, transportation, and energy sectors. The demand for electromagnetic power failure brakes is increasing due to their ability to enhance operational safety and efficiency. They are particularly valued in environments where sudden stops are necessary to prevent accidents or equipment damage. As industries continue to prioritize safety and automation, the adoption of these brakes is expected to grow, supported by technological advancements that improve their performance and reliability. The market is characterized by a diverse range of products tailored to specific industrial needs, offering solutions that cater to various load capacities and operational conditions. This adaptability makes electromagnetic power failure brakes a versatile choice for businesses looking to enhance their safety protocols and operational efficiency.

Tooth, Multiple Disc, Hysteresis, Magnetic Particle in the Electromagnetic Power Failure Brake - Global Market:

Electromagnetic power failure brakes come in various types, each designed to meet specific industrial requirements. Tooth brakes, for instance, are known for their high torque capacity and are often used in applications where precise stopping is crucial. These brakes engage by meshing teeth on the rotor and stator, providing a secure hold even in power-off conditions. Their robust design makes them ideal for heavy-duty applications, such as in the mining and construction industries, where equipment must be stopped quickly and reliably. Multiple disc brakes, on the other hand, consist of several friction discs that provide a larger surface area for braking, resulting in higher torque and smoother operation. These brakes are commonly used in machinery that requires frequent starts and stops, such as in manufacturing and assembly lines. Hysteresis brakes utilize magnetic fields to create resistance, offering smooth and consistent braking without physical contact between components. This design reduces wear and tear, making hysteresis brakes suitable for applications where maintenance downtime must be minimized. Lastly, magnetic particle brakes use magnetic particles suspended in a fluid to transmit torque. When an electromagnetic field is applied, the particles align and create resistance, providing precise control over braking force. This type of brake is often used in applications requiring variable torque, such as in tension control systems in the paper and textile industries. Each type of electromagnetic power failure brake offers unique advantages, allowing industries to select the most appropriate solution based on their specific operational needs and safety requirements.

Mining Industry, Metallurgy, Construction, Power Generation, Transportation, Others in the Electromagnetic Power Failure Brake - Global Market:

The usage of electromagnetic power failure brakes spans across various industries, each benefiting from their unique capabilities. In the mining industry, these brakes are essential for ensuring the safety of heavy machinery and equipment. They provide reliable stopping power in the event of a power failure, preventing accidents and equipment damage in hazardous environments. The ability to stop machinery quickly and safely is crucial in mining operations, where the risk of accidents is high. In the metallurgy industry, electromagnetic power failure brakes are used to control the movement of heavy materials and machinery. They ensure precise stopping and holding of equipment, which is vital for maintaining the quality and consistency of metal products. The construction industry also relies on these brakes to enhance the safety and efficiency of cranes, hoists, and other heavy equipment. Electromagnetic power failure brakes provide the necessary stopping power to prevent accidents and ensure the safe handling of materials. In the power generation sector, these brakes are used in wind turbines and other equipment to control rotational speed and prevent damage during power outages. Their ability to provide fail-safe braking is crucial for maintaining the stability and reliability of power generation systems. The transportation industry benefits from electromagnetic power failure brakes in various applications, including trains and elevators, where safety and precision are paramount. These brakes ensure smooth and reliable stopping, enhancing passenger safety and comfort. Other industries, such as manufacturing and automation, also utilize electromagnetic power failure brakes to improve operational safety and efficiency. Their versatility and reliability make them an indispensable component in a wide range of industrial applications.

Electromagnetic Power Failure Brake - Global Market Outlook:

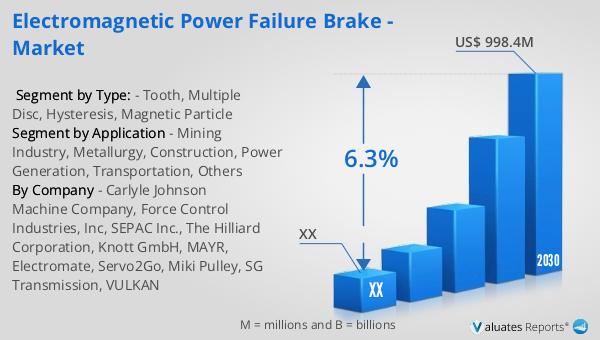

The global market for electromagnetic power failure brakes was valued at approximately $647 million in 2023. It is projected to grow significantly, reaching an estimated size of $998.4 million by 2030. This growth represents a compound annual growth rate (CAGR) of 6.3% during the forecast period from 2024 to 2030. The North American market, in particular, is expected to see substantial growth, although specific figures for this region were not provided. The increasing demand for safety and automation in various industries is driving the market expansion. As industries continue to prioritize operational safety and efficiency, the adoption of electromagnetic power failure brakes is expected to rise. Technological advancements in brake design and materials are also contributing to market growth, offering improved performance and reliability. The market is characterized by a diverse range of products, catering to different industrial needs and applications. This adaptability makes electromagnetic power failure brakes a versatile choice for businesses looking to enhance their safety protocols and operational efficiency. As the market continues to evolve, manufacturers are focusing on developing innovative solutions to meet the growing demand for fail-safe braking systems.

| Report Metric | Details |

| Report Name | Electromagnetic Power Failure Brake - Market |

| Forecasted market size in 2030 | US$ 998.4 million |

| CAGR | 6.3% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Carlyle Johnson Machine Company, Force Control Industries, Inc, SEPAC Inc., The Hilliard Corporation, Knott GmbH, MAYR, Electromate, Servo2Go, Miki Pulley, SG Transmission, VULKAN |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |