What is Coating Thickness Measurement System - Global Market?

Coating Thickness Measurement Systems are essential tools in various industries to ensure the quality and longevity of products by accurately measuring the thickness of coatings applied to surfaces. These systems are crucial in maintaining product standards, preventing material wastage, and ensuring compliance with industry regulations. The global market for these systems is expanding due to increasing demand across sectors such as automotive, aerospace, and electronics, where precise coating measurements are vital. The systems employ different technologies, including magnetic, eddy current, and ultrasonic methods, to measure coatings on various substrates like metals, plastics, and ceramics. As industries continue to innovate and develop new materials and coatings, the need for advanced and reliable coating thickness measurement systems is expected to grow. This growth is driven by the need for improved product performance, durability, and aesthetic appeal, which are directly influenced by the quality and consistency of coatings. The market's expansion is also supported by technological advancements that enhance the accuracy, ease of use, and versatility of these measurement systems, making them indispensable tools in quality control processes across diverse industries.

Ultrasonic Coating Thickness Measurement System, Magnetic Coating Thickness Measurement System, Digital Display Coating Thickness Measurement System, Others in the Coating Thickness Measurement System - Global Market:

Ultrasonic Coating Thickness Measurement Systems are widely used for non-destructive testing of coatings on non-metal substrates. These systems utilize high-frequency sound waves to penetrate coatings and measure their thickness without causing any damage to the material. This method is particularly beneficial for measuring coatings on plastics, composites, and other non-metallic surfaces where traditional methods may not be applicable. Ultrasonic systems are valued for their precision and ability to measure multiple layers of coatings, making them ideal for complex applications in industries such as aerospace and automotive. Magnetic Coating Thickness Measurement Systems, on the other hand, are primarily used for measuring coatings on ferrous metals. These systems work by detecting changes in magnetic fields caused by the presence of a coating, providing accurate measurements of coating thickness. They are commonly used in industries like automotive and construction, where metal substrates are prevalent. Digital Display Coating Thickness Measurement Systems offer the advantage of easy-to-read digital outputs, enhancing user convenience and reducing the likelihood of human error. These systems often incorporate advanced features such as data storage, statistical analysis, and connectivity options, making them suitable for modern industrial environments. Other types of coating thickness measurement systems include eddy current systems, which are used for non-ferrous metal substrates, and X-ray fluorescence systems, which provide highly accurate measurements for a wide range of materials. Each type of system has its unique advantages and applications, catering to the diverse needs of industries that rely on precise coating measurements to ensure product quality and performance. As the global market for coating thickness measurement systems continues to grow, driven by technological advancements and increasing demand for high-quality products, these systems are becoming more sophisticated and versatile, offering enhanced capabilities to meet the evolving needs of various industries.

Industrial and Automotive, Chemical Industry, Electronic and Metals, Aerospace and Marine, Other in the Coating Thickness Measurement System - Global Market:

Coating Thickness Measurement Systems play a crucial role in various industries by ensuring the quality and durability of products. In the industrial and automotive sectors, these systems are used to measure the thickness of paint and other coatings on vehicles and machinery. Accurate coating measurements are essential for maintaining the aesthetic appeal and corrosion resistance of automotive parts, as well as ensuring the longevity and performance of industrial equipment. In the chemical industry, coating thickness measurement systems are used to monitor the application of protective coatings on storage tanks, pipelines, and other infrastructure to prevent corrosion and chemical damage. These systems help ensure compliance with safety and environmental regulations by verifying that coatings are applied correctly and consistently. In the electronics and metals industries, coating thickness measurement systems are used to measure the thickness of conductive and non-conductive coatings on electronic components and metal products. Precise coating measurements are critical for ensuring the functionality and reliability of electronic devices, as well as the durability and appearance of metal products. In the aerospace and marine industries, coating thickness measurement systems are used to measure the thickness of protective coatings on aircraft and marine vessels. These coatings are essential for protecting against harsh environmental conditions and ensuring the safety and performance of aircraft and ships. Other industries that rely on coating thickness measurement systems include construction, where they are used to measure the thickness of coatings on building materials, and the medical industry, where they are used to measure coatings on medical devices and implants. As the demand for high-quality, durable products continues to grow, the use of coating thickness measurement systems is becoming increasingly important across a wide range of industries.

Coating Thickness Measurement System - Global Market Outlook:

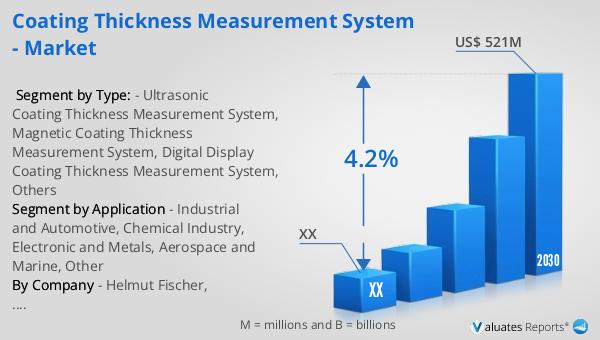

The global market for Coating Thickness Measurement Systems was valued at approximately $388 million in 2023. It is projected to grow to a size of around $521 million by 2030, reflecting a compound annual growth rate (CAGR) of 4.2% during the forecast period from 2024 to 2030. This growth is indicative of the increasing demand for precise and reliable coating measurement solutions across various industries. In North America, the market for these systems was valued at a significant amount in 2023, with expectations of continued growth through 2030. The CAGR for the North American market during this period is anticipated to align with the global trend, driven by advancements in technology and the rising need for quality assurance in manufacturing processes. The expansion of the market is supported by the adoption of innovative measurement technologies that enhance accuracy and efficiency, catering to the evolving needs of industries such as automotive, aerospace, and electronics. As industries continue to prioritize quality and compliance, the demand for advanced coating thickness measurement systems is expected to rise, contributing to the overall growth of the market.

| Report Metric | Details |

| Report Name | Coating Thickness Measurement System - Market |

| Forecasted market size in 2030 | US$ 521 million |

| CAGR | 4.2% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Helmut Fischer, Fischer Measurement Technologies (India) Pvt., Elcometer Limited, EMG Automation, KLA, Obsnap Group, PCE Instruments, Agr International, Zumbach Electronic (Shanghai) Co., Ltd., Cefem Group, Anton Paar, MEXTECH, Cygnus Instruments, DFT Meter, Samruddhi Industries |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |