What is UV Light Curing Conveyor - Global Market?

The UV Light Curing Conveyor is a specialized piece of equipment used in various industries to cure or dry materials using ultraviolet (UV) light. This technology is particularly valuable in processes where quick drying and hardening are essential, such as in the production of adhesives, coatings, and inks. The global market for UV Light Curing Conveyors is expanding due to the increasing demand for efficient and environmentally friendly curing solutions. These conveyors are designed to provide consistent and uniform exposure to UV light, ensuring that materials are cured evenly and quickly. They are used in a wide range of applications, from small-scale operations to large industrial processes. The market growth is driven by advancements in UV technology, which have made these systems more efficient and cost-effective. Additionally, the push for greener technologies has led to a preference for UV curing over traditional methods that may involve harmful chemicals. As industries continue to seek ways to improve production efficiency and reduce environmental impact, the demand for UV Light Curing Conveyors is expected to rise.

Countertop Type, Floor-standing Type in the UV Light Curing Conveyor - Global Market:

The UV Light Curing Conveyor market can be segmented into different types based on their design and application, notably the countertop type and floor-standing type. The countertop type UV Light Curing Conveyor is compact and designed for smaller-scale operations or laboratories where space is limited. These units are ideal for businesses that require a portable and efficient curing solution without the need for extensive floor space. They are often used in applications where precision and control are paramount, such as in the electronics industry for curing small components or in the printing industry for curing inks on smaller items. The countertop models are typically user-friendly, with easy-to-use controls and quick setup times, making them suitable for environments where flexibility and adaptability are crucial. On the other hand, the floor-standing type UV Light Curing Conveyor is designed for larger-scale industrial applications. These units are robust and capable of handling high-volume production processes. They are often used in industries such as automotive and large-scale printing, where the curing of large parts or continuous production lines is required. Floor-standing conveyors are built to withstand the rigors of industrial use, offering durability and reliability. They often come with advanced features such as adjustable conveyor speeds, variable UV intensity, and integrated cooling systems to ensure optimal curing conditions. The choice between countertop and floor-standing types depends largely on the specific needs of the business, including the scale of production, available space, and the nature of the materials being cured. Both types play a crucial role in enhancing production efficiency and product quality across various industries. As the demand for UV curing technology continues to grow, manufacturers are focusing on developing more versatile and efficient conveyor systems to meet the diverse needs of their customers. This includes innovations in UV lamp technology, energy efficiency, and automation, which are expected to drive further growth in the UV Light Curing Conveyor market.

Automobile Industry, Electronic Industry, Printing Industry, Others in the UV Light Curing Conveyor - Global Market:

UV Light Curing Conveyors are utilized across various industries due to their efficiency and effectiveness in curing processes. In the automobile industry, these conveyors are used to cure coatings and adhesives applied to vehicle parts. The quick curing time provided by UV light ensures that production lines can operate smoothly without delays, enhancing overall productivity. This technology is particularly beneficial in the automotive sector, where precision and durability are critical. UV curing helps in achieving high-quality finishes on parts, which are essential for both aesthetic and functional purposes. In the electronic industry, UV Light Curing Conveyors are employed to cure adhesives and coatings on electronic components. The precision offered by UV curing is crucial in this sector, where even minor imperfections can lead to significant issues in product performance. The ability to cure materials quickly and uniformly ensures that electronic components meet the stringent quality standards required in this industry. In the printing industry, UV Light Curing Conveyors are used to cure inks and coatings on various substrates. The rapid curing process allows for faster production speeds and reduces the risk of smudging or other defects. This is particularly important in high-volume printing operations where efficiency and quality are paramount. Additionally, UV curing is environmentally friendly, as it eliminates the need for solvents and reduces emissions. Beyond these industries, UV Light Curing Conveyors find applications in other sectors such as medical device manufacturing, where they are used to cure coatings and adhesives on medical equipment. The versatility and efficiency of UV curing technology make it an attractive option for any industry that requires quick and reliable curing solutions. As industries continue to evolve and seek more efficient production methods, the use of UV Light Curing Conveyors is likely to expand further.

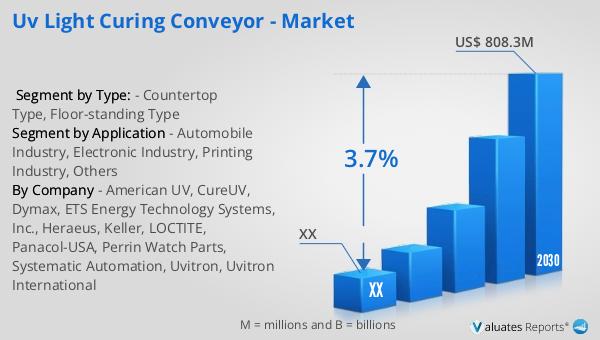

UV Light Curing Conveyor - Global Market Outlook:

The global market for UV Light Curing Conveyors was valued at approximately $580 million in 2023. It is projected to grow to a revised size of $808.3 million by 2030, reflecting a compound annual growth rate (CAGR) of 3.7% during the forecast period from 2024 to 2030. This growth is indicative of the increasing demand for efficient and environmentally friendly curing solutions across various industries. The North American market, in particular, is expected to see significant growth, although specific figures for this region were not provided. The anticipated growth in the global market can be attributed to several factors, including advancements in UV technology, the push for greener production methods, and the increasing need for efficient curing solutions in industries such as automotive, electronics, and printing. As businesses continue to seek ways to improve production efficiency and reduce environmental impact, the demand for UV Light Curing Conveyors is expected to rise. This market outlook highlights the potential for growth and innovation in the UV Light Curing Conveyor industry, as manufacturers focus on developing more versatile and efficient systems to meet the diverse needs of their customers.

| Report Metric | Details |

| Report Name | UV Light Curing Conveyor - Market |

| Forecasted market size in 2030 | US$ 808.3 million |

| CAGR | 3.7% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | American UV, CureUV, Dymax, ETS Energy Technology Systems, Inc., Heraeus, Keller, LOCTITE, Panacol-USA, Perrin Watch Parts, Systematic Automation, Uvitron, Uvitron International |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |