What is Thermoplastic PP Honeycomb Core - Global Market?

Thermoplastic PP Honeycomb Core is a lightweight, durable material used in various industries due to its excellent strength-to-weight ratio. This core is made from polypropylene (PP), a type of thermoplastic polymer known for its versatility and resistance to chemical and physical stress. The honeycomb structure, inspired by natural honeycombs, provides exceptional mechanical properties, making it ideal for applications requiring high strength and low weight. The global market for Thermoplastic PP Honeycomb Core is expanding as industries seek materials that offer both performance and sustainability. This material is particularly valued in sectors like aerospace, automotive, and construction, where reducing weight without compromising strength is crucial. The market's growth is driven by increasing demand for lightweight materials, advancements in manufacturing technologies, and the rising focus on eco-friendly products. As industries continue to innovate and prioritize efficiency, the Thermoplastic PP Honeycomb Core market is poised for significant development, offering solutions that meet the evolving needs of modern engineering and design.

Square Structure, Hexagonal Structure in the Thermoplastic PP Honeycomb Core - Global Market:

The Thermoplastic PP Honeycomb Core market features two primary structural designs: square and hexagonal. Each structure offers unique benefits and is chosen based on specific application requirements. The square structure is characterized by its grid-like pattern, providing uniform strength and stability across its surface. This design is particularly advantageous in applications where consistent load distribution is essential. The square structure's simplicity allows for easy integration into various products, making it a popular choice in industries like construction and automotive. On the other hand, the hexagonal structure mimics the natural honeycomb pattern found in beehives, offering superior strength and energy absorption capabilities. This design is highly efficient in distributing stress and minimizing material usage, making it ideal for applications requiring high impact resistance and lightweight properties. The hexagonal structure is often preferred in aerospace and military applications, where performance and safety are paramount. Both structures leverage the inherent benefits of thermoplastic PP, such as resistance to moisture, chemicals, and temperature variations, ensuring durability and longevity in demanding environments. The choice between square and hexagonal structures depends on factors like load requirements, environmental conditions, and cost considerations. As the global market for Thermoplastic PP Honeycomb Core continues to grow, manufacturers are investing in research and development to enhance these structures' performance and expand their application range. Innovations in material science and manufacturing processes are expected to further optimize the properties of both square and hexagonal structures, offering tailored solutions for diverse industry needs. The versatility of Thermoplastic PP Honeycomb Core, combined with its structural options, positions it as a key material in the pursuit of lightweight, high-performance solutions across various sectors.

Aerospace, Military, Automobile, Architecture, Industrial Equipment, Other in the Thermoplastic PP Honeycomb Core - Global Market:

Thermoplastic PP Honeycomb Core finds extensive usage across multiple industries due to its unique properties. In the aerospace sector, this material is prized for its lightweight nature, which contributes to fuel efficiency and reduced emissions. Its high strength-to-weight ratio ensures that aircraft components can withstand significant stress while maintaining structural integrity. The military sector also benefits from Thermoplastic PP Honeycomb Core, utilizing it in applications such as vehicle armor and protective gear. Its ability to absorb impact and resist harsh environmental conditions makes it ideal for defense purposes. In the automotive industry, this core material is used in vehicle interiors, panels, and bumpers, where reducing weight is crucial for improving fuel efficiency and performance. The architecture industry leverages Thermoplastic PP Honeycomb Core for building facades, partitions, and flooring, taking advantage of its durability and aesthetic versatility. Industrial equipment manufacturers incorporate this material into machinery and equipment that require lightweight yet robust components. Beyond these sectors, Thermoplastic PP Honeycomb Core is also used in sports equipment, packaging, and marine applications, showcasing its adaptability and wide-ranging benefits. As industries continue to prioritize sustainability and efficiency, the demand for Thermoplastic PP Honeycomb Core is expected to rise, driving further innovation and application development.

Thermoplastic PP Honeycomb Core - Global Market Outlook:

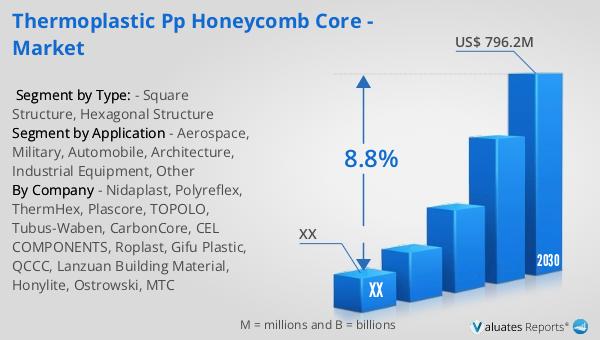

The global market for Thermoplastic PP Honeycomb Core was valued at approximately $444 million in 2023. It is projected to grow significantly, reaching an estimated size of $796.2 million by 2030. This growth represents a compound annual growth rate (CAGR) of 8.8% during the forecast period from 2024 to 2030. The North American market, in particular, is expected to experience substantial growth, although specific figures for this region were not provided. The increasing demand for lightweight and durable materials across various industries is a key driver of this market expansion. As sectors like aerospace, automotive, and construction continue to seek materials that offer both performance and sustainability, the Thermoplastic PP Honeycomb Core market is poised for significant development. The market's growth is further supported by advancements in manufacturing technologies and the rising focus on eco-friendly products. As industries continue to innovate and prioritize efficiency, the Thermoplastic PP Honeycomb Core market is expected to offer solutions that meet the evolving needs of modern engineering and design.

| Report Metric | Details |

| Report Name | Thermoplastic PP Honeycomb Core - Market |

| Forecasted market size in 2030 | US$ 796.2 million |

| CAGR | 8.8% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Nidaplast, Polyreflex, ThermHex, Plascore, TOPOLO, Tubus-Waben, CarbonCore, CEL COMPONENTS, Roplast, Gifu Plastic, QCCC, Lanzuan Building Material, Honylite, Ostrowski, MTC |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |