What is Silver Tungsten Carbide Graphite Electrical Contacts and Assemblies - Global Market?

Silver Tungsten Carbide Graphite Electrical Contacts and Assemblies are specialized components used in various electrical applications due to their unique properties. These contacts are made by combining silver, tungsten carbide, and graphite, each contributing distinct characteristics to the final product. Silver offers excellent electrical conductivity, making it ideal for efficient current transfer. Tungsten carbide provides hardness and wear resistance, ensuring durability even under high-stress conditions. Graphite adds lubricating properties, reducing friction and wear during operation. Together, these materials create a composite that is highly effective in demanding electrical environments. The global market for these contacts and assemblies is driven by the increasing demand for reliable and efficient electrical components across various industries. As technology advances, the need for components that can withstand high temperatures, resist corrosion, and maintain performance over time becomes more critical. This market is characterized by continuous innovation and development, aiming to enhance the performance and cost-effectiveness of these electrical contacts. Manufacturers are focusing on improving the material composition and production processes to meet the evolving needs of industries such as automotive, aerospace, and energy. The global market outlook for these products is promising, with potential growth driven by technological advancements and increasing industrial applications.

Below 70%, 70%-80%, Above 80% in the Silver Tungsten Carbide Graphite Electrical Contacts and Assemblies - Global Market:

In the global market for Silver Tungsten Carbide Graphite Electrical Contacts and Assemblies, the composition of silver in the contacts plays a crucial role in determining their performance and cost. The market can be segmented based on the silver content into three categories: below 70%, 70%-80%, and above 80%. Contacts with below 70% silver content are typically more cost-effective, making them suitable for applications where budget constraints are a priority. These contacts still offer decent conductivity and durability, but they may not perform as well in extremely demanding environments. The 70%-80% silver content category strikes a balance between cost and performance. These contacts are widely used in applications that require reliable conductivity and moderate wear resistance. They are a popular choice in industries where both performance and cost are important considerations. Contacts with above 80% silver content are at the premium end of the market. They offer superior electrical conductivity and wear resistance, making them ideal for high-performance applications. These contacts are often used in critical systems where reliability and longevity are paramount. The choice of silver content in these contacts depends on the specific requirements of the application, including factors such as electrical load, environmental conditions, and budget. Manufacturers in the global market are continuously exploring ways to optimize the silver content to enhance performance while managing costs. This involves research and development efforts to improve material formulations and production techniques. The market dynamics for these contacts are influenced by technological advancements, industry standards, and the evolving needs of end-users. As industries continue to demand more efficient and durable electrical components, the market for Silver Tungsten Carbide Graphite Electrical Contacts and Assemblies is expected to grow, driven by innovations in material science and manufacturing processes.

DC Switching Equipment, MCB, Heavy Duty Relay, Others in the Silver Tungsten Carbide Graphite Electrical Contacts and Assemblies - Global Market:

Silver Tungsten Carbide Graphite Electrical Contacts and Assemblies are utilized in various applications, including DC switching equipment, miniature circuit breakers (MCBs), heavy-duty relays, and other electrical systems. In DC switching equipment, these contacts are essential for ensuring reliable and efficient current transfer. The combination of silver, tungsten carbide, and graphite provides the necessary conductivity, durability, and lubrication to handle the high currents and frequent switching operations typical in DC systems. This makes them ideal for use in renewable energy systems, electric vehicles, and other applications where DC power is prevalent. In MCBs, these contacts play a critical role in protecting electrical circuits from overloads and short circuits. The high conductivity of silver ensures quick response times, while the wear resistance of tungsten carbide and the lubricating properties of graphite enhance the longevity and reliability of the circuit breakers. This is particularly important in residential, commercial, and industrial settings where electrical safety is a top priority. Heavy-duty relays also benefit from the unique properties of these contacts. The robust construction and excellent conductivity make them suitable for handling high power loads and frequent switching cycles. This is crucial in applications such as industrial automation, power distribution, and transportation systems, where reliable performance is essential. Beyond these specific applications, Silver Tungsten Carbide Graphite Electrical Contacts and Assemblies are used in various other electrical systems that require high-performance components. Their versatility and effectiveness make them a preferred choice in many industries, including aerospace, automotive, and telecommunications. As technology continues to evolve, the demand for these advanced electrical contacts is expected to increase, driven by the need for more efficient and reliable electrical systems.

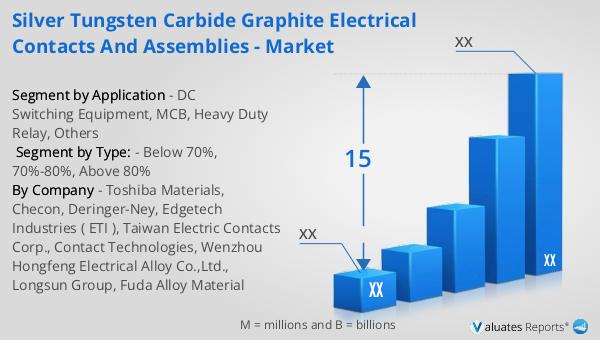

Silver Tungsten Carbide Graphite Electrical Contacts and Assemblies - Global Market Outlook:

In the market outlook for Silver Tungsten Carbide Graphite Electrical Contacts and Assemblies, an innovative approach involves adding a copper layer to form AgWCCCu contacts. This modification can lead to significant cost savings, ranging from 15% to 30%, without compromising the product's performance. The global market for these contacts was valued at several million US dollars in 2023, with projections indicating a readjusted market size by 2030. The compound annual growth rate (CAGR) for the period from 2024 to 2030 is expected to reflect steady growth, driven by the increasing demand for efficient and cost-effective electrical components. The addition of a copper layer enhances the overall conductivity and thermal management of the contacts, making them even more suitable for high-performance applications. This innovation is particularly appealing to industries looking to optimize their operational costs while maintaining high standards of reliability and efficiency. As the market continues to evolve, manufacturers are likely to explore further enhancements and material combinations to meet the diverse needs of their customers. The focus on cost reduction and performance improvement is expected to drive the adoption of these advanced electrical contacts across various sectors, contributing to the overall growth of the global market.

| Report Metric | Details |

| Report Name | Silver Tungsten Carbide Graphite Electrical Contacts and Assemblies - Market |

| CAGR | 15 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Toshiba Materials, Checon, Deringer-Ney, Edgetech Industries ( ETI ), Taiwan Electric Contacts Corp., Contact Technologies, Wenzhou Hongfeng Electrical Alloy Co.,Ltd., Longsun Group, Fuda Alloy Material |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |