What is Sand Aggregates Crushing and Screening Machine - Global Market?

Sand aggregates crushing and screening machines are essential tools in the construction and mining industries, playing a pivotal role in breaking down large rocks and stones into smaller, more manageable pieces. These machines are designed to handle various types of materials, including sand, gravel, and crushed stone, which are crucial for building infrastructure like roads, bridges, and buildings. The global market for these machines is driven by the increasing demand for construction materials, fueled by urbanization and infrastructure development worldwide. As countries continue to invest in new construction projects, the need for efficient and reliable crushing and screening equipment grows. These machines not only help in reducing the size of raw materials but also ensure that the final product meets specific quality standards. With advancements in technology, modern sand aggregates crushing and screening machines are becoming more efficient, environmentally friendly, and capable of handling larger volumes of material, making them indispensable in the global construction landscape.

Horizontal Type, Vertical Type in the Sand Aggregates Crushing and Screening Machine - Global Market:

When it comes to sand aggregates crushing and screening machines, there are two primary types based on their orientation: horizontal and vertical. Horizontal type machines are designed with a horizontal shaft, which allows them to process materials in a linear motion. This type of machine is particularly effective for handling softer materials and is often used in applications where a consistent and uniform product size is required. Horizontal machines are known for their versatility and ability to produce high-quality aggregates with minimal fines. They are commonly used in the production of sand and gravel, as well as in recycling applications where the material needs to be processed quickly and efficiently. On the other hand, vertical type machines feature a vertical shaft, which enables them to crush materials using a combination of impact and attrition. This type of machine is ideal for processing harder materials, such as granite and basalt, and is often used in applications where a high reduction ratio is required. Vertical machines are known for their ability to produce cubical-shaped aggregates, which are highly desirable in the construction industry. They are also capable of handling larger feed sizes and can produce a wide range of product sizes, making them suitable for a variety of applications. Both horizontal and vertical type machines have their own unique advantages and are used in different scenarios depending on the specific requirements of the project. As the global market for sand aggregates crushing and screening machines continues to grow, manufacturers are constantly innovating and improving their products to meet the evolving needs of the industry. This includes the development of more efficient and environmentally friendly machines that can handle larger volumes of material while minimizing energy consumption and emissions. With the increasing demand for high-quality construction materials, the market for both horizontal and vertical type machines is expected to expand, providing opportunities for manufacturers to introduce new and improved products that cater to the diverse needs of their customers.

Stone Aggregate, Sand Aggregate in the Sand Aggregates Crushing and Screening Machine - Global Market:

The usage of sand aggregates crushing and screening machines is crucial in the production of both stone and sand aggregates, which are essential components in the construction industry. Stone aggregates are produced by crushing large rocks and stones into smaller pieces, which are then screened to ensure they meet specific size and quality requirements. These aggregates are used in a variety of applications, including the construction of roads, bridges, and buildings, as well as in the production of concrete and asphalt. The ability to produce high-quality stone aggregates is essential for ensuring the durability and longevity of construction projects, making crushing and screening machines an indispensable tool in the industry. Similarly, sand aggregates are produced by crushing and screening natural sand deposits or by processing crushed stone to produce sand-sized particles. Sand aggregates are used in a wide range of applications, including the production of concrete, mortar, and plaster, as well as in the construction of roads and other infrastructure projects. The quality of sand aggregates is critical for ensuring the strength and stability of construction materials, making the use of efficient and reliable crushing and screening machines essential. As the demand for construction materials continues to grow, the need for high-quality stone and sand aggregates is expected to increase, driving the demand for advanced crushing and screening machines that can produce these materials efficiently and cost-effectively. With advancements in technology, modern machines are becoming more efficient and capable of producing a wider range of product sizes, allowing manufacturers to meet the diverse needs of their customers. This includes the development of machines that can handle larger volumes of material, produce higher quality aggregates, and minimize energy consumption and emissions, making them more environmentally friendly and sustainable.

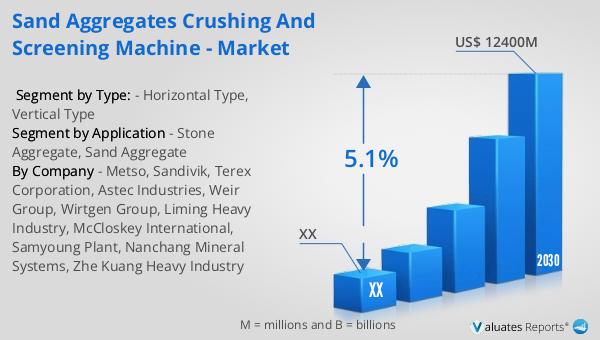

Sand Aggregates Crushing and Screening Machine - Global Market Outlook:

The global market for sand aggregates crushing and screening machines was valued at approximately $8,736 million in 2023. It is projected to grow to a revised size of $12,400 million by 2030, reflecting a compound annual growth rate (CAGR) of 5.1% during the forecast period from 2024 to 2030. This growth is driven by the increasing demand for construction materials, fueled by urbanization and infrastructure development worldwide. In North America, the market for these machines was valued at $ million in 2023 and is expected to reach $ million by 2030, with a CAGR of % during the forecast period. The growth in this region is attributed to the ongoing construction and infrastructure projects, as well as the increasing demand for high-quality aggregates. As the market continues to expand, manufacturers are focusing on developing more efficient and environmentally friendly machines that can meet the evolving needs of the industry. This includes the introduction of new technologies and innovations that can improve the performance and efficiency of crushing and screening machines, as well as reduce their environmental impact. With the increasing demand for construction materials, the global market for sand aggregates crushing and screening machines is expected to continue its growth trajectory, providing opportunities for manufacturers to introduce new and improved products that cater to the diverse needs of their customers.

| Report Metric | Details |

| Report Name | Sand Aggregates Crushing and Screening Machine - Market |

| Forecasted market size in 2030 | US$ 12400 million |

| CAGR | 5.1% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Metso, Sandivik, Terex Corporation, Astec Industries, Weir Group, Wirtgen Group, Liming Heavy Industry, McCloskey International, Samyoung Plant, Nanchang Mineral Systems, Zhe Kuang Heavy Industry |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |