What is Robotic Cathode Copper Stripping Machine - Global Market?

Robotic Cathode Copper Stripping Machines are specialized equipment used in the copper refining industry to automate the process of stripping copper cathodes. These machines are designed to enhance efficiency, safety, and precision in the copper production process. By utilizing robotic technology, these machines can handle the heavy and repetitive task of stripping copper sheets from cathodes, which are used in the electrolytic refining process. This automation not only reduces the need for manual labor but also minimizes the risk of injury and human error. The global market for these machines is driven by the increasing demand for copper, which is a critical material in various industries such as electronics, construction, and transportation. As industries continue to grow and evolve, the need for efficient and reliable copper production processes becomes more crucial, thereby boosting the demand for robotic cathode copper stripping machines. These machines are becoming an integral part of modern copper refineries, helping to streamline operations and improve overall productivity.

0-700 Piece/Hour, 700-800 Piece/Hour, Above 800 Piece/Hour in the Robotic Cathode Copper Stripping Machine - Global Market:

The global market for Robotic Cathode Copper Stripping Machines can be segmented based on their operational capacity, typically measured in pieces per hour. The first category, 0-700 pieces per hour, represents machines that are suitable for smaller operations or facilities with lower production demands. These machines are often more affordable and require less energy, making them ideal for companies that are just starting out or those that do not need to produce large quantities of copper. Despite their lower capacity, these machines still offer the benefits of automation, such as increased safety and reduced labor costs. The second category, 700-800 pieces per hour, caters to medium-sized operations. These machines strike a balance between cost and capacity, providing a good option for companies that are expanding their production capabilities. They offer a higher throughput than the lower capacity machines, allowing for more efficient processing of copper cathodes. This category is popular among companies that are looking to scale up their operations without making a significant investment in high-capacity equipment. The third category, above 800 pieces per hour, is designed for large-scale operations that require high levels of production. These machines are typically used by major copper producers who need to process large volumes of copper quickly and efficiently. While they represent a larger investment, the increased capacity and efficiency can lead to significant cost savings in the long run. These machines are equipped with advanced features and technologies to ensure optimal performance and reliability. As the demand for copper continues to rise, the need for high-capacity robotic cathode copper stripping machines is expected to grow, driving innovation and development in this segment of the market. Each of these categories serves a specific niche within the copper refining industry, allowing companies to choose the right machine based on their production needs and budget. By offering a range of capacities, the market for robotic cathode copper stripping machines can cater to a diverse array of customers, from small-scale operations to large industrial producers. This segmentation also highlights the versatility and adaptability of these machines, as they can be tailored to meet the specific requirements of different production environments. As technology continues to advance, we can expect to see further improvements in the efficiency and capabilities of these machines, making them an even more valuable asset in the copper refining process.

Copper Electrolytic Refining, Copper Electrodeposition in the Robotic Cathode Copper Stripping Machine - Global Market:

Robotic Cathode Copper Stripping Machines play a crucial role in the copper electrolytic refining and electrodeposition processes. In copper electrolytic refining, these machines are used to automate the removal of copper sheets from cathodes after the electrolysis process. This process involves passing an electric current through a solution containing dissolved copper, causing pure copper to deposit onto the cathode plates. Once the copper has been deposited, the robotic stripping machine efficiently removes the copper sheets, allowing for continuous production without the need for manual intervention. This automation not only speeds up the refining process but also ensures a consistent quality of the copper produced. In copper electrodeposition, the role of robotic cathode copper stripping machines is similarly vital. Electrodeposition is a process used to coat a conductive surface with a layer of copper, often used in the manufacturing of electronic components and circuit boards. The precision and consistency offered by robotic stripping machines ensure that the copper layers are uniform and free from defects, which is essential for the performance and reliability of electronic devices. By automating the stripping process, these machines help to reduce production costs and improve the overall efficiency of the electrodeposition process. The use of robotic cathode copper stripping machines in these areas highlights their importance in modern copper production. By streamlining operations and reducing the reliance on manual labor, these machines contribute to a more sustainable and efficient copper industry. As the demand for high-quality copper continues to grow, the adoption of robotic stripping machines is likely to increase, further enhancing the capabilities of copper refineries and electrodeposition facilities. The integration of these machines into the copper production process not only improves productivity but also helps to ensure the safety and well-being of workers by reducing their exposure to hazardous conditions. Overall, the use of robotic cathode copper stripping machines in copper electrolytic refining and electrodeposition represents a significant advancement in the industry, offering numerous benefits in terms of efficiency, quality, and safety.

Robotic Cathode Copper Stripping Machine - Global Market Outlook:

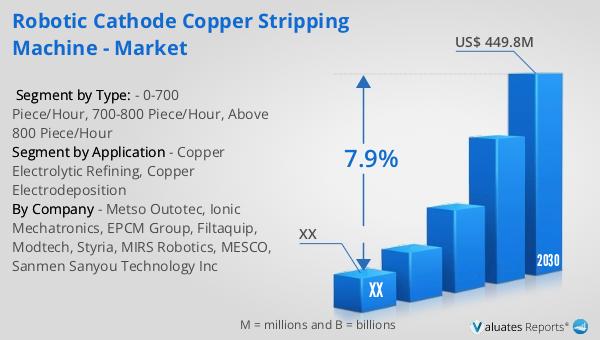

In 2023, the global market for Robotic Cathode Copper Stripping Machines was valued at approximately $255 million. This market is projected to grow significantly, reaching an estimated size of $449.8 million by 2030, with a compound annual growth rate (CAGR) of 7.9% during the forecast period from 2024 to 2030. This growth reflects the increasing demand for efficient and automated solutions in the copper refining industry. The North American market for these machines also shows promising potential, although specific figures for 2023 and 2030 are not provided. The anticipated growth in this region is expected to align with the global trend, driven by advancements in technology and the need for more efficient copper production processes. As industries continue to expand and the demand for copper rises, the market for robotic cathode copper stripping machines is likely to see continued growth and development. This positive outlook underscores the importance of these machines in modern copper production, as they offer significant benefits in terms of efficiency, safety, and cost savings. The projected growth in the market highlights the increasing recognition of the value that robotic cathode copper stripping machines bring to the copper refining industry, making them an essential component of future production strategies.

| Report Metric | Details |

| Report Name | Robotic Cathode Copper Stripping Machine - Market |

| Forecasted market size in 2030 | US$ 449.8 million |

| CAGR | 7.9% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Metso Outotec, Ionic Mechatronics, EPCM Group, Filtaquip, Modtech, Styria, MIRS Robotics, MESCO, Sanmen Sanyou Technology Inc |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |