What is Energy Storage Battery Tray - Global Market?

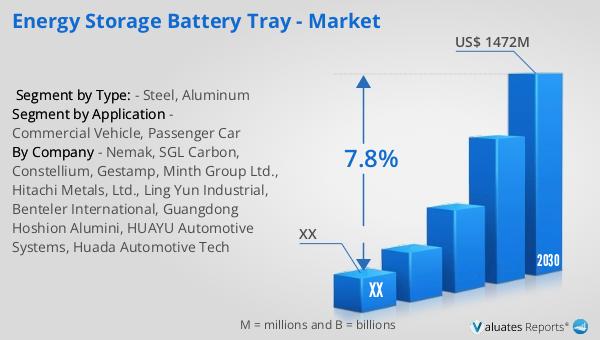

The global market for energy storage battery trays is a rapidly evolving sector, driven by the increasing demand for efficient energy storage solutions across various industries. These trays are essential components in the assembly of battery packs, providing structural support and protection to the battery cells. As the world shifts towards renewable energy sources and electric vehicles, the need for reliable and durable battery trays has become more pronounced. In 2023, the market was valued at approximately US$ 875 million, and it is projected to grow significantly, reaching an estimated US$ 1472 million by 2030. This growth is expected to occur at a compound annual growth rate (CAGR) of 7.8% from 2024 to 2030. The market's expansion is fueled by technological advancements, increased production of electric vehicles, and the growing emphasis on sustainable energy solutions. The energy storage battery tray market is a critical component of the broader energy storage industry, playing a vital role in ensuring the safety, efficiency, and longevity of battery systems used in various applications. As industries continue to innovate and adapt to changing energy needs, the demand for high-quality battery trays is expected to rise, further driving market growth.

Steel, Aluminum in the Energy Storage Battery Tray - Global Market:

In the context of energy storage battery trays, materials like steel and aluminum play a crucial role in determining the performance, durability, and cost-effectiveness of the trays. Steel, known for its strength and durability, is often used in battery trays to provide robust structural support. Its high tensile strength ensures that the battery cells are securely held in place, reducing the risk of damage during transportation or operation. Steel trays are particularly favored in applications where weight is not a primary concern, such as in larger commercial vehicles or stationary energy storage systems. However, the weight of steel can be a disadvantage in applications where reducing the overall weight of the vehicle or system is critical. On the other hand, aluminum offers a lightweight alternative to steel, making it an attractive option for energy storage battery trays in electric vehicles and other applications where weight reduction is essential. Aluminum's lower density compared to steel allows for significant weight savings, which can enhance the efficiency and range of electric vehicles. Additionally, aluminum is highly resistant to corrosion, which is a valuable property in environments where the battery trays may be exposed to moisture or other corrosive elements. The use of aluminum in battery trays also contributes to improved thermal management, as aluminum has excellent thermal conductivity, helping to dissipate heat generated by the battery cells. This can enhance the overall performance and lifespan of the battery system. Despite these advantages, aluminum trays can be more expensive to produce than steel trays, which can impact the overall cost of the battery system. The choice between steel and aluminum for energy storage battery trays often depends on the specific requirements of the application, including factors such as weight, cost, and environmental conditions. In some cases, manufacturers may opt for a hybrid approach, using a combination of steel and aluminum to balance the benefits of both materials. This approach can provide the necessary strength and durability while also achieving weight reduction and cost-effectiveness. As the demand for energy storage solutions continues to grow, the development of new materials and manufacturing techniques is likely to further enhance the performance and cost-efficiency of battery trays. Innovations such as advanced alloys, composite materials, and additive manufacturing could offer new possibilities for optimizing the design and production of energy storage battery trays. These advancements could lead to lighter, stronger, and more affordable trays, supporting the continued growth of the energy storage market. Ultimately, the choice of material for energy storage battery trays will depend on a careful consideration of the specific needs and constraints of each application, as well as the evolving landscape of material science and manufacturing technology.

Commercial Vehicle, Passenger Car in the Energy Storage Battery Tray - Global Market:

Energy storage battery trays are integral to the functionality and safety of both commercial vehicles and passenger cars, particularly as the automotive industry increasingly embraces electrification. In commercial vehicles, such as buses and trucks, battery trays must accommodate larger battery packs to support the higher energy demands of these vehicles. The trays provide a secure housing for the battery cells, protecting them from physical damage and environmental factors such as moisture, dust, and temperature fluctuations. This protection is crucial for maintaining the reliability and longevity of the battery system, which is essential for commercial vehicles that often operate under demanding conditions and cover long distances. Additionally, the design of battery trays for commercial vehicles must consider factors such as weight distribution and ease of maintenance, as these can impact the vehicle's performance and operational efficiency. In passenger cars, energy storage battery trays play a similar role in ensuring the safety and performance of the vehicle's battery system. However, the design considerations for passenger car battery trays often prioritize weight reduction and compactness, as these factors can significantly influence the vehicle's range and handling. Lightweight materials such as aluminum are commonly used in passenger car battery trays to achieve these goals, while still providing the necessary structural support and protection for the battery cells. The trays must also be designed to accommodate the specific layout and configuration of the battery pack, which can vary depending on the vehicle model and manufacturer. As electric vehicles become more prevalent, the demand for efficient and reliable battery trays in both commercial vehicles and passenger cars is expected to increase. Manufacturers are continually exploring new materials and design innovations to enhance the performance and cost-effectiveness of battery trays, supporting the broader transition to sustainable transportation solutions. The development of standardized designs and modular tray systems could further streamline production processes and reduce costs, making electric vehicles more accessible to a wider range of consumers. Overall, energy storage battery trays are a critical component of the automotive industry's shift towards electrification, playing a key role in ensuring the safety, efficiency, and sustainability of modern vehicles.

Energy Storage Battery Tray - Global Market Outlook:

The global market for energy storage battery trays was valued at approximately US$ 875 million in 2023, with projections indicating a significant increase to around US$ 1472 million by 2030. This anticipated growth reflects a compound annual growth rate (CAGR) of 7.8% during the forecast period from 2024 to 2030. The market's expansion is largely driven by the increasing adoption of electric vehicles and the growing emphasis on renewable energy solutions. Currently, over 90% of the world's automobiles are concentrated in Asia, Europe, and North America. Asia leads in automobile production, accounting for 56% of the global output, followed by Europe at 20% and North America at 16%. This concentration highlights the significant role these regions play in the automotive industry and the potential impact of their transition towards electrification on the energy storage battery tray market. As these regions continue to invest in electric vehicle infrastructure and technology, the demand for high-quality battery trays is expected to rise, further fueling market growth. The energy storage battery tray market is poised to benefit from these trends, as manufacturers seek to develop innovative solutions that meet the evolving needs of the automotive and energy sectors.

| Report Metric | Details |

| Report Name | Energy Storage Battery Tray - Market |

| Forecasted market size in 2030 | US$ 1472 million |

| CAGR | 7.8% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Nemak, SGL Carbon, Constellium, Gestamp, Minth Group Ltd., Hitachi Metals, Ltd., Ling Yun Industrial, Benteler International, Guangdong Hoshion Alumini, HUAYU Automotive Systems, Huada Automotive Tech |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |