What is Medical Orthopedic Implant Forgings - Global Market?

Medical orthopedic implant forgings refer to the specialized manufacturing process used to create durable and precise components for orthopedic implants. These implants are crucial in medical procedures that involve the replacement or reinforcement of bones and joints. The global market for these forgings is driven by the increasing demand for orthopedic surgeries, which are often necessitated by aging populations, sports injuries, and accidents. The process of forging involves shaping metal using compressive forces, which enhances the strength and reliability of the final product. This is particularly important in medical applications where the implants must withstand significant stress and strain over time. The market is characterized by advancements in technology that allow for more precise and customized implants, catering to the specific needs of patients. Additionally, the rise in healthcare expenditure and the growing awareness of advanced medical treatments contribute to the expansion of this market. As a result, manufacturers are focusing on innovation and quality to meet the stringent standards required in the medical field, ensuring that the implants are both safe and effective for long-term use.

Metal Material, High-Polymer Material, Ceramic Material, Compound Material in the Medical Orthopedic Implant Forgings - Global Market:

In the realm of medical orthopedic implant forgings, various materials are employed to meet the diverse needs of patients and the specific requirements of different surgical procedures. Metal materials, such as titanium and stainless steel, are commonly used due to their excellent strength, durability, and biocompatibility. Titanium, in particular, is favored for its lightweight nature and resistance to corrosion, making it ideal for implants that need to integrate seamlessly with human bone. Stainless steel, while heavier, offers cost-effectiveness and is often used in temporary implants. High-polymer materials, including polyethylene and polymethylmethacrylate (PMMA), are utilized for their flexibility and ability to mimic the properties of natural cartilage. These materials are often used in joint replacement surgeries, where smooth articulation is crucial. Ceramic materials, such as alumina and zirconia, are prized for their hardness and wear resistance, making them suitable for load-bearing applications like hip and knee replacements. They also offer excellent biocompatibility and are less likely to provoke an immune response. Compound materials, which combine the properties of metals, polymers, and ceramics, are increasingly being developed to offer enhanced performance. These materials aim to provide the strength of metals, the flexibility of polymers, and the wear resistance of ceramics, resulting in implants that are both robust and adaptable. The choice of material depends on various factors, including the specific application, the patient's health condition, and the surgeon's preference. As the global market for medical orthopedic implant forgings continues to grow, the development and refinement of these materials play a crucial role in advancing the field of orthopedic surgery. Manufacturers are investing in research and development to create materials that not only meet the current demands but also anticipate future needs, ensuring that patients receive the best possible care.

Spinal Fusion, Long Bone, Foot & Ankle, Craniomaxillofacial, Joint Replacement in the Medical Orthopedic Implant Forgings - Global Market:

Medical orthopedic implant forgings are utilized in a variety of surgical applications, each with its own specific requirements and challenges. In spinal fusion procedures, these forgings are used to create implants that stabilize the spine by promoting the fusion of two or more vertebrae. The implants must be strong enough to support the spine while allowing for natural movement, making the choice of material and design critical. For long bone surgeries, such as those involving the femur or tibia, orthopedic implants provide structural support and facilitate the healing process. These implants often need to withstand significant weight and stress, requiring materials that offer both strength and flexibility. In foot and ankle surgeries, implants are used to correct deformities, repair fractures, and replace damaged joints. The small size and complex structure of the foot and ankle demand precise and durable implants that can accommodate the intricate movements of these areas. Craniomaxillofacial surgeries, which involve the bones of the skull and face, utilize implants to reconstruct and repair facial structures. These implants must be lightweight and biocompatible, ensuring that they integrate well with the surrounding bone and tissue. Joint replacement surgeries, such as those for the hip or knee, rely heavily on orthopedic implant forgings to restore mobility and alleviate pain. The implants used in these procedures must be able to withstand the repetitive motion and load-bearing demands of daily activities. Across all these applications, the primary goal is to create implants that enhance patient outcomes by providing stability, promoting healing, and restoring function. The global market for medical orthopedic implant forgings is driven by the need for innovative solutions that address the unique challenges of each surgical application, ensuring that patients receive the best possible care.

Medical Orthopedic Implant Forgings - Global Market Outlook:

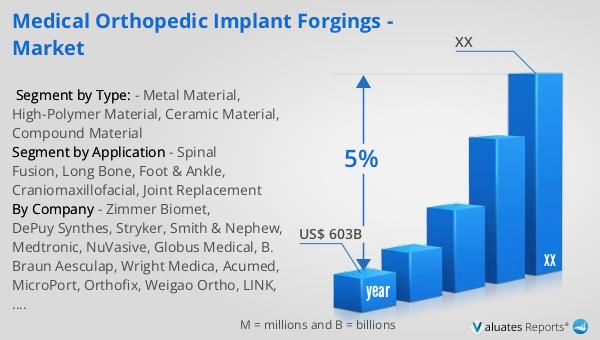

Our research indicates that the global market for medical devices, which includes medical orthopedic implant forgings, is projected to reach approximately $603 billion in 2023. This substantial market size reflects the growing demand for advanced medical technologies and the increasing prevalence of conditions that require surgical intervention. Over the next six years, the market is expected to grow at a compound annual growth rate (CAGR) of 5%. This growth is driven by several factors, including the aging global population, rising healthcare expenditures, and advancements in medical technology. As more people seek medical treatments to improve their quality of life, the demand for reliable and effective orthopedic implants continues to rise. Manufacturers are responding to this demand by investing in research and development to create innovative products that meet the evolving needs of patients and healthcare providers. The market outlook for medical orthopedic implant forgings is positive, with opportunities for growth and innovation as the industry adapts to changing healthcare landscapes and technological advancements. This growth trajectory underscores the importance of continued investment in the development of high-quality, durable, and biocompatible materials that can enhance patient outcomes and support the future of orthopedic surgery.

| Report Metric | Details |

| Report Name | Medical Orthopedic Implant Forgings - Market |

| Accounted market size in year | US$ 603 billion |

| CAGR | 5% |

| Base Year | year |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Zimmer Biomet, DePuy Synthes, Stryker, Smith & Nephew, Medtronic, NuVasive, Globus Medical, B. Braun Aesculap, Wright Medica, Acumed, MicroPort, Orthofix, Weigao Ortho, LINK, Johnson & Johnson, Naton, Arthrex, Komal Health Care |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |