What is Medical Irradiation Processing Services - Global Market?

Medical irradiation processing services refer to the use of radiation technology to sterilize medical products and supplies, ensuring they are free from harmful microorganisms. This global market is essential for maintaining the safety and efficacy of medical devices, pharmaceuticals, and other healthcare products. The process involves exposing these items to controlled doses of radiation, which effectively eliminates bacteria, viruses, and other pathogens. This method is highly efficient and reliable, making it a preferred choice for sterilization in the medical industry. The global market for medical irradiation processing services is driven by the increasing demand for sterile medical products, advancements in radiation technology, and stringent regulatory requirements for product safety. As healthcare systems worldwide continue to expand and evolve, the need for effective sterilization solutions becomes even more critical. This market encompasses various irradiation techniques, including gamma radiation and electron beam irradiation, each offering unique benefits and applications. The growth of this market is also supported by the rising prevalence of healthcare-associated infections, which underscores the importance of maintaining high standards of hygiene and safety in medical settings. Overall, medical irradiation processing services play a vital role in ensuring the quality and safety of healthcare products on a global scale.

Gamma Radiation, Electron Beam Irradiation in the Medical Irradiation Processing Services - Global Market:

Gamma radiation and electron beam irradiation are two primary methods used in medical irradiation processing services, each with distinct characteristics and applications. Gamma radiation involves the use of high-energy photons, typically emitted from isotopes like Cobalt-60, to sterilize medical products. This method is highly effective in penetrating dense materials and complex geometries, making it suitable for a wide range of medical devices, including surgical instruments, implants, and pharmaceutical products. Gamma radiation is known for its deep penetration capabilities, allowing it to sterilize products in bulk and in their final packaging, which is a significant advantage for manufacturers. The process is also relatively simple and requires minimal handling, reducing the risk of contamination. However, the use of radioactive isotopes necessitates stringent safety measures and regulatory compliance to ensure safe operation and disposal. On the other hand, electron beam irradiation, or e-beam, utilizes high-energy electrons to sterilize medical products. This method is characterized by its rapid processing times and high throughput, making it ideal for large-scale production environments. E-beam irradiation is particularly effective for surface sterilization and is often used for products that are sensitive to heat or moisture, such as certain pharmaceuticals and medical supplies. Unlike gamma radiation, e-beam does not rely on radioactive materials, which simplifies safety and regulatory requirements. The equipment used for e-beam irradiation can be turned on and off as needed, providing greater flexibility and control over the sterilization process. However, the penetration depth of e-beam is generally less than that of gamma radiation, which may limit its use for certain products with complex shapes or dense materials. Both gamma radiation and electron beam irradiation offer unique advantages and are chosen based on the specific requirements of the medical products being sterilized. Factors such as material compatibility, product geometry, and production volume play a crucial role in determining the most suitable irradiation method. In some cases, a combination of both techniques may be employed to achieve optimal sterilization results. The global market for medical irradiation processing services continues to grow as healthcare providers and manufacturers seek reliable and efficient sterilization solutions to meet the increasing demand for safe and sterile medical products. As technology advances, further innovations in irradiation techniques are expected to enhance the efficiency and effectiveness of these services, contributing to improved healthcare outcomes worldwide.

Medical Supplies, Health Medicine, Other in the Medical Irradiation Processing Services - Global Market:

Medical irradiation processing services are utilized extensively across various sectors, including medical supplies, health medicine, and other related fields. In the realm of medical supplies, irradiation is crucial for sterilizing items such as surgical instruments, syringes, catheters, and wound care products. These supplies must be free from any microbial contamination to prevent infections during medical procedures. The use of irradiation ensures that these products meet stringent safety standards, providing healthcare professionals with the confidence to use them in patient care. The ability to sterilize products in their final packaging also helps maintain sterility until the point of use, reducing the risk of contamination during handling and transportation. In the health medicine sector, irradiation processing services are employed to sterilize pharmaceuticals, including vaccines, biologics, and other injectable drugs. These products require a high level of sterility to ensure patient safety and efficacy. Irradiation offers a non-thermal sterilization method that preserves the integrity and potency of heat-sensitive pharmaceuticals. This is particularly important for biologics and vaccines, which may be compromised by traditional heat-based sterilization methods. By using irradiation, manufacturers can ensure that their products remain safe and effective throughout their shelf life. Beyond medical supplies and health medicine, irradiation processing services are also used in other areas such as laboratory research, biotechnology, and food safety. In laboratory settings, irradiation is used to sterilize equipment, media, and other materials to prevent contamination in experiments and research studies. In biotechnology, irradiation is employed to ensure the sterility of cell cultures, reagents, and other critical components used in the development of new therapies and diagnostics. Additionally, irradiation is increasingly being used in the food industry to enhance food safety by reducing the microbial load on products, thereby extending shelf life and reducing the risk of foodborne illnesses. Overall, the global market for medical irradiation processing services plays a vital role in ensuring the safety and efficacy of a wide range of products across multiple sectors. As the demand for sterile medical supplies and pharmaceuticals continues to grow, the importance of reliable and efficient irradiation services becomes even more pronounced. By providing a safe and effective means of sterilization, irradiation processing services contribute to improved healthcare outcomes and enhanced public health on a global scale.

Medical Irradiation Processing Services - Global Market Outlook:

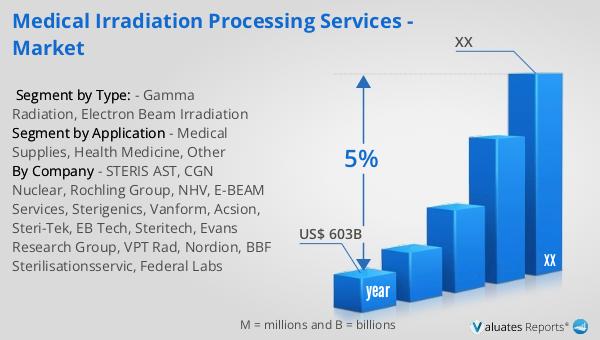

Our research indicates that the global market for medical devices is projected to reach approximately $603 billion in 2023, with an anticipated growth rate of 5% annually over the next six years. This growth trajectory underscores the increasing demand for medical devices across various healthcare sectors, driven by advancements in technology, an aging population, and the rising prevalence of chronic diseases. As healthcare systems worldwide strive to improve patient outcomes and enhance the quality of care, the need for innovative and effective medical devices becomes more critical. This market expansion is also fueled by the growing emphasis on personalized medicine and the integration of digital technologies in healthcare delivery. The adoption of advanced medical devices, such as wearable health monitors, minimally invasive surgical instruments, and smart diagnostic tools, is transforming the way healthcare is delivered and managed. Furthermore, the increasing focus on preventive healthcare and early diagnosis is driving the demand for diagnostic devices and equipment. As the global market for medical devices continues to evolve, manufacturers and healthcare providers must adapt to changing consumer needs and regulatory requirements to remain competitive. By leveraging cutting-edge technologies and innovative solutions, the medical device industry is poised to play a pivotal role in shaping the future of healthcare.

| Report Metric | Details |

| Report Name | Medical Irradiation Processing Services - Market |

| Accounted market size in year | US$ 603 billion |

| CAGR | 5% |

| Base Year | year |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | STERIS AST, CGN Nuclear, Rochling Group, NHV, E-BEAM Services, Sterigenics, Vanform, Acsion, Steri-Tek, EB Tech, Steritech, Evans Research Group, VPT Rad, Nordion, BBF Sterilisationsservic, Federal Labs |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |