What is Hot Melt Coater - Global Market?

The Hot Melt Coater - Global Market refers to the industry surrounding machines that apply hot melt adhesives onto various substrates. These machines are essential in numerous manufacturing processes, providing a quick and efficient way to bond materials. Hot melt coaters are particularly valued for their ability to deliver precise and consistent adhesive application, which is crucial in industries where product quality and performance are paramount. The global market for these machines is driven by their versatility and efficiency, as they can be used in a wide range of applications, from packaging to textiles. The demand for hot melt coaters is also fueled by the growing need for sustainable and environmentally friendly adhesive solutions, as they often use less energy and produce fewer emissions compared to traditional adhesive methods. As industries continue to seek ways to improve efficiency and reduce environmental impact, the hot melt coater market is expected to see continued growth and innovation.

Roll Coating, Spray Coating, Slot Die Coating in the Hot Melt Coater - Global Market:

Hot melt coating technology encompasses several methods, each with its unique advantages and applications. Roll coating is one of the most common techniques, where the adhesive is applied to a substrate using a series of rollers. This method is particularly effective for large-scale production processes, as it allows for continuous application and can handle a wide range of substrate thicknesses. Roll coating is often used in industries such as automotive and packaging, where large volumes of material need to be coated quickly and efficiently. Spray coating, on the other hand, involves the application of adhesive through a spray nozzle, allowing for more precise control over the amount and distribution of adhesive. This method is ideal for applications where uniform coverage is critical, such as in the electronics industry, where even a small amount of excess adhesive can cause significant issues. Spray coating is also beneficial for coating irregularly shaped or textured surfaces, as the spray can reach areas that rollers might miss. Slot die coating is another popular method, where the adhesive is extruded through a slot die onto the substrate. This technique offers exceptional precision and control, making it ideal for applications that require a high degree of accuracy, such as in the production of thin films or coatings for electronic components. Slot die coating is also highly efficient, as it minimizes waste and ensures consistent coverage across the entire substrate. Each of these methods has its own set of advantages and is chosen based on the specific requirements of the application, the type of substrate being used, and the desired properties of the final product. As the global market for hot melt coaters continues to grow, manufacturers are constantly innovating and improving these technologies to meet the evolving needs of their customers.

Automotive, Electronics, Packaging, Textiles, Printing, Others in the Hot Melt Coater - Global Market:

The usage of hot melt coaters spans a wide range of industries, each benefiting from the unique properties and advantages of hot melt adhesives. In the automotive industry, hot melt coaters are used to apply adhesives for bonding various components, such as interior panels, trim, and insulation materials. The quick setting time and strong bond strength of hot melt adhesives make them ideal for automotive applications, where durability and reliability are critical. In the electronics industry, hot melt coaters are used to apply adhesives for assembling components, such as circuit boards and displays. The precision and control offered by hot melt coating methods, such as spray and slot die coating, are essential for ensuring the performance and reliability of electronic devices. In the packaging industry, hot melt coaters are used to seal boxes, cartons, and other packaging materials. The fast setting time and strong bond strength of hot melt adhesives make them ideal for high-speed packaging lines, where efficiency and reliability are paramount. In the textiles industry, hot melt coaters are used to apply adhesives for bonding fabrics and other materials. The flexibility and durability of hot melt adhesives make them ideal for textile applications, where the finished product needs to withstand wear and tear. In the printing industry, hot melt coaters are used to apply adhesives for binding books and other printed materials. The strong bond strength and quick setting time of hot melt adhesives make them ideal for high-speed printing operations, where efficiency and quality are critical. Other industries, such as construction and woodworking, also benefit from the use of hot melt coaters, as they provide a quick and efficient way to bond materials. As the demand for hot melt adhesives continues to grow, the global market for hot melt coaters is expected to see continued growth and innovation, as manufacturers seek to improve the efficiency and performance of their products.

Hot Melt Coater - Global Market Outlook:

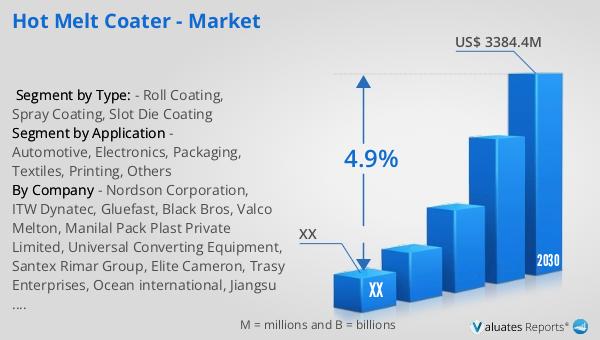

The global market for Hot Melt Coater was valued at approximately US$ 2,410 million in 2023, with projections indicating a growth to around US$ 3,384.4 million by 2030. This represents a compound annual growth rate (CAGR) of 4.9% over the forecast period from 2024 to 2030. The increasing demand for hot melt coating machines is largely driven by strong requirements from end-user sectors such as paper and board, nonwoven, and flexible packaging. These segments collectively account for more than half of the total global consumption of hot melt coaters. The growth in these sectors is attributed to the rising need for efficient and sustainable adhesive solutions, as well as the ongoing trend towards automation and high-speed production processes. As industries continue to evolve and adapt to changing market conditions, the demand for hot melt coaters is expected to remain strong, with manufacturers focusing on developing innovative solutions to meet the diverse needs of their customers. The market outlook for hot melt coaters is positive, with continued growth anticipated as industries seek to improve efficiency, reduce environmental impact, and enhance product quality.

| Report Metric | Details |

| Report Name | Hot Melt Coater - Market |

| Forecasted market size in 2030 | US$ 3384.4 million |

| CAGR | 4.9% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Nordson Corporation, ITW Dynatec, Gluefast, Black Bros, Valco Melton, Manilal Pack Plast Private Limited, Universal Converting Equipment, Santex Rimar Group, Elite Cameron, Trasy Enterprises, Ocean international, Jiangsu SangDion Machinery, Toray Engineering, Jiayuan Machine, New Era Converting Machinery |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |