What is High Value-Added Investment Casting - Global Market?

High Value-Added Investment Casting is a sophisticated manufacturing process that involves creating intricate metal components with high precision and minimal material waste. This technique is particularly valuable in industries that demand complex geometries and high-performance materials. The global market for High Value-Added Investment Casting is driven by the increasing demand for lightweight and durable components in sectors such as aerospace, automotive, and industrial machinery. The process begins with the creation of a wax model, which is then coated with a ceramic shell. Once the shell hardens, the wax is melted away, leaving a cavity that is filled with molten metal. This method allows for the production of parts with excellent surface finishes and tight tolerances. The market is characterized by advancements in material science and casting technologies, which enhance the performance and reliability of the final products. As industries continue to seek ways to improve efficiency and reduce environmental impact, High Value-Added Investment Casting offers a viable solution by enabling the production of components that are both lightweight and strong. This market is poised for growth as technological innovations and increasing applications across various sectors drive demand.

Nickel, Titanium, Stainless Steel, Aluminum in the High Value-Added Investment Casting - Global Market:

Nickel, titanium, stainless steel, and aluminum are key materials used in High Value-Added Investment Casting, each offering unique properties that cater to specific industry needs. Nickel-based alloys are renowned for their exceptional resistance to heat and corrosion, making them ideal for high-temperature applications such as turbine blades and engine components. These alloys maintain their strength and stability even under extreme conditions, which is crucial for the aerospace and power generation industries. Titanium, on the other hand, is celebrated for its high strength-to-weight ratio and excellent corrosion resistance. It is extensively used in aerospace applications where reducing weight without compromising strength is paramount. Titanium castings are also employed in medical devices and chemical processing equipment due to their biocompatibility and resistance to corrosive environments. Stainless steel is another versatile material in investment casting, known for its durability, corrosion resistance, and aesthetic appeal. It is widely used in the automotive, food processing, and construction industries. Stainless steel castings are favored for their ability to withstand harsh environments and maintain structural integrity over time. Aluminum, with its lightweight and excellent thermal conductivity, is a preferred choice for components that require efficient heat dissipation and reduced weight. It is commonly used in the automotive and aerospace sectors to enhance fuel efficiency and performance. The global market for High Value-Added Investment Casting is witnessing a growing demand for these materials as industries strive to improve product performance and sustainability. Advances in casting technologies and material science are enabling the production of more complex and reliable components, further driving the adoption of investment casting across various sectors. As industries continue to evolve, the versatility and superior properties of nickel, titanium, stainless steel, and aluminum will play a crucial role in meeting the demands of modern manufacturing.

Aerospace, Defense, Industrial Gas Turbine in the High Value-Added Investment Casting - Global Market:

High Value-Added Investment Casting plays a pivotal role in the aerospace, defense, and industrial gas turbine sectors, where precision, reliability, and performance are paramount. In the aerospace industry, investment casting is used to produce critical components such as turbine blades, engine parts, and structural components. The ability to create complex geometries with high precision ensures that these parts meet the stringent performance and safety standards required in aviation. The lightweight and durable nature of cast components also contribute to fuel efficiency and overall aircraft performance. In the defense sector, investment casting is employed to manufacture components for military vehicles, weapons systems, and communication equipment. The process allows for the production of parts that can withstand harsh environments and demanding operational conditions. The use of advanced materials such as titanium and nickel-based alloys ensures that these components offer superior strength and resistance to wear and corrosion. In the industrial gas turbine sector, investment casting is crucial for producing components that operate under high temperatures and pressures. Turbine blades and vanes, for instance, require materials that can maintain their integrity and performance in extreme conditions. Investment casting provides the precision and material properties needed to ensure the efficiency and reliability of gas turbines used in power generation and other industrial applications. The global market for High Value-Added Investment Casting is driven by the continuous demand for high-performance components in these sectors. As technology advances and industries seek to enhance efficiency and sustainability, investment casting offers a reliable solution for producing complex and durable parts. The ability to tailor material properties and achieve intricate designs makes investment casting an indispensable process in the aerospace, defense, and industrial gas turbine industries.

High Value-Added Investment Casting - Global Market Outlook:

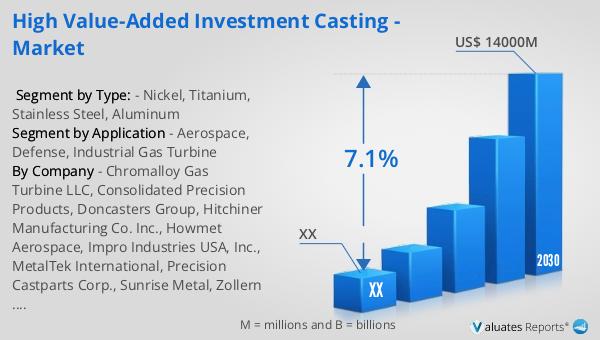

The global market for High Value-Added Investment Casting was valued at approximately $8,660 million in 2023, and it is projected to grow significantly, reaching an estimated size of $14,000 million by 2030. This growth is expected to occur at a compound annual growth rate (CAGR) of 7.1% during the forecast period from 2024 to 2030. This upward trend reflects the increasing demand for precision-engineered components across various industries, driven by advancements in technology and material science. The North American market, a significant contributor to the global landscape, is also anticipated to experience substantial growth during this period. Although specific figures for the North American market were not provided, it is expected to follow a similar growth trajectory, supported by the region's strong industrial base and focus on innovation. The expansion of the High Value-Added Investment Casting market is indicative of the broader trend towards lightweight, durable, and high-performance components that meet the evolving needs of industries such as aerospace, automotive, and energy. As manufacturers continue to seek ways to enhance efficiency and reduce environmental impact, the demand for investment casting is likely to remain robust, driving further growth and development in this dynamic market.

| Report Metric | Details |

| Report Name | High Value-Added Investment Casting - Market |

| Forecasted market size in 2030 | US$ 14000 million |

| CAGR | 7.1% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Chromalloy Gas Turbine LLC, Consolidated Precision Products, Doncasters Group, Hitchiner Manufacturing Co. Inc., Howmet Aerospace, Impro Industries USA, Inc., MetalTek International, Precision Castparts Corp., Sunrise Metal, Zollern GmbH & Co. KG |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |