What is High Pressure Hydrogen Valve - Global Market?

High pressure hydrogen valves are crucial components in the global market, primarily used in systems that handle hydrogen gas under high pressure. These valves are designed to control the flow of hydrogen, ensuring safety and efficiency in various applications. The global market for these valves is driven by the increasing adoption of hydrogen as a clean energy source, which is part of the broader push towards sustainable energy solutions. As industries and governments worldwide invest in hydrogen infrastructure, the demand for high pressure hydrogen valves is expected to grow. These valves are essential in applications such as hydrogen refueling stations, on-board hydrogen supply systems, and fuel cell systems, where they play a critical role in managing the safe and efficient flow of hydrogen. The market is characterized by technological advancements aimed at improving valve performance, durability, and safety features. Manufacturers are focusing on developing valves that can withstand extreme conditions and offer precise control over hydrogen flow. As the hydrogen economy expands, the high pressure hydrogen valve market is poised for significant growth, driven by innovations and increasing investments in hydrogen technologies.

Solenoid Valves, Reduction Valves, Check Valves, Others in the High Pressure Hydrogen Valve - Global Market:

Solenoid valves, reduction valves, check valves, and other types of valves are integral to the high pressure hydrogen valve market, each serving distinct functions within hydrogen systems. Solenoid valves are electrically controlled devices that manage the flow of hydrogen by opening or closing in response to an electric signal. These valves are favored for their precision and reliability, making them ideal for automated systems where accurate control of hydrogen flow is crucial. Solenoid valves are often used in hydrogen refueling stations and fuel cell systems, where they help regulate the flow of hydrogen to ensure optimal performance and safety. Reduction valves, on the other hand, are designed to reduce the pressure of hydrogen gas from a high-pressure source to a lower, more manageable level. These valves are essential in applications where hydrogen needs to be delivered at a specific pressure, such as in on-board hydrogen supply systems for vehicles. By maintaining a consistent pressure, reduction valves help ensure the safe and efficient operation of hydrogen-powered systems. Check valves are another critical component, allowing hydrogen to flow in one direction while preventing backflow. This feature is vital in preventing contamination and ensuring the integrity of hydrogen systems. Check valves are commonly used in various hydrogen applications, including refueling stations and fuel cell systems, where they help maintain the purity and quality of hydrogen gas. Other types of valves in the high pressure hydrogen valve market include ball valves, gate valves, and needle valves, each offering unique features and benefits. Ball valves, for example, provide a tight seal and are easy to operate, making them suitable for applications where quick and reliable shut-off is required. Gate valves are used in applications where a straight-line flow of hydrogen with minimal restriction is needed, while needle valves offer precise control over hydrogen flow, making them ideal for fine-tuning applications. As the demand for hydrogen as a clean energy source continues to grow, the market for high pressure hydrogen valves, including solenoid, reduction, check, and other types of valves, is expected to expand. Manufacturers are investing in research and development to enhance valve performance, durability, and safety, ensuring they meet the evolving needs of the hydrogen industry.

Hydrogen Refueling Station, On-board Hydrogen Supply System, Fuel Cell System in the High Pressure Hydrogen Valve - Global Market:

High pressure hydrogen valves are used in various applications, including hydrogen refueling stations, on-board hydrogen supply systems, and fuel cell systems, each requiring specific valve functions to ensure safety and efficiency. In hydrogen refueling stations, these valves play a crucial role in managing the flow of hydrogen from storage tanks to vehicles. Solenoid valves are often used in these stations to control the dispensing of hydrogen, ensuring precise and safe refueling. Reduction valves are also essential in refueling stations, as they help reduce the pressure of hydrogen from storage tanks to a level suitable for vehicle refueling. Check valves are used to prevent backflow, ensuring the purity and quality of hydrogen dispensed to vehicles. On-board hydrogen supply systems in vehicles rely on high pressure hydrogen valves to manage the flow of hydrogen from storage tanks to fuel cells or combustion engines. Reduction valves are critical in these systems, as they ensure hydrogen is delivered at the correct pressure for efficient operation. Solenoid valves are used to control the flow of hydrogen within the vehicle, allowing for precise management of hydrogen supply to the engine or fuel cell. Check valves are also used to prevent backflow and maintain system integrity. In fuel cell systems, high pressure hydrogen valves are used to regulate the flow of hydrogen to the fuel cell stack, where it is converted into electricity. Solenoid valves are commonly used in these systems to ensure precise control of hydrogen flow, optimizing fuel cell performance and efficiency. Reduction valves help maintain the correct pressure of hydrogen supplied to the fuel cell, while check valves prevent backflow and contamination. As the hydrogen economy continues to grow, the demand for high pressure hydrogen valves in these applications is expected to increase, driven by the need for safe and efficient hydrogen systems. Manufacturers are focusing on developing advanced valve technologies to meet the specific requirements of each application, ensuring the safe and reliable operation of hydrogen systems.

High Pressure Hydrogen Valve - Global Market Outlook:

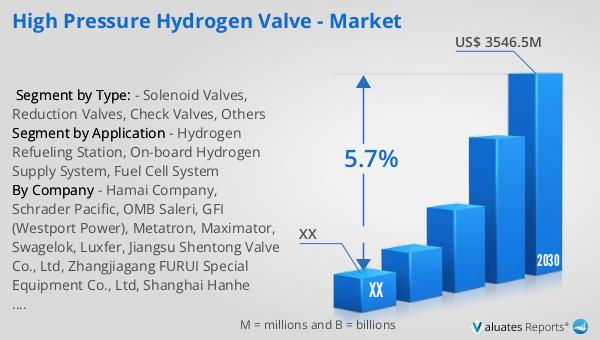

The global market for high pressure hydrogen valves was valued at approximately $2,394 million in 2023. This market is projected to grow significantly, reaching an estimated size of $3,546.5 million by 2030, with a compound annual growth rate (CAGR) of 5.7% during the forecast period from 2024 to 2030. This growth is driven by the increasing adoption of hydrogen as a clean energy source and the expansion of hydrogen infrastructure worldwide. In North America, the market for high pressure hydrogen valves is also expected to grow, although specific figures for this region were not provided. The growth in North America will likely be influenced by investments in hydrogen technologies and infrastructure, as well as government initiatives to promote clean energy solutions. As the demand for hydrogen as a sustainable energy source continues to rise, the market for high pressure hydrogen valves is poised for significant expansion, driven by technological advancements and increasing investments in hydrogen systems. Manufacturers are focusing on developing innovative valve solutions to meet the evolving needs of the hydrogen industry, ensuring the safe and efficient operation of hydrogen systems across various applications.

| Report Metric | Details |

| Report Name | High Pressure Hydrogen Valve - Market |

| Forecasted market size in 2030 | US$ 3546.5 million |

| CAGR | 5.7% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Hamai Company, Schrader Pacific, OMB Saleri, GFI (Westport Power), Metatron, Maximator, Swagelok, Luxfer, Jiangsu Shentong Valve Co., Ltd, Zhangjiagang FURUI Special Equipment Co., Ltd, Shanghai Hanhe Power Technology Co., Ltd, Ftxt Energy Technology Co., Ltd |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |