What is Hazardous Area Cameras - Global Market?

Hazardous area cameras are specialized devices designed to operate safely in environments where there is a risk of explosion due to the presence of flammable gases, vapors, dust, or fibers. These cameras are crucial in industries such as oil and gas, chemical manufacturing, and mining, where monitoring and surveillance are essential for safety and operational efficiency. The global market for hazardous area cameras is driven by the increasing need for safety and security in these high-risk environments. These cameras are built to withstand harsh conditions and are often equipped with features like infrared vision, high-definition imaging, and remote monitoring capabilities. They help in ensuring compliance with safety regulations and standards, thereby preventing accidents and ensuring the safety of personnel and equipment. As industries continue to prioritize safety and technological advancements make these cameras more efficient and reliable, the demand for hazardous area cameras is expected to grow. The market is characterized by a variety of products tailored to meet the specific needs of different industries, with manufacturers focusing on innovation to enhance the functionality and durability of these cameras.

Integrated Type, Distributed Type in the Hazardous Area Cameras - Global Market:

In the realm of hazardous area cameras, two primary types are prevalent: integrated type and distributed type. Integrated type cameras are designed to be compact and self-contained units that combine all necessary components, such as the camera, housing, and power supply, into a single device. This design makes them ideal for environments where space is limited or where a streamlined installation is preferred. Integrated cameras are often used in fixed locations where consistent monitoring is required, such as in chemical plants or oil refineries. They offer ease of installation and maintenance, as all components are housed within a single unit, reducing the need for additional wiring or external connections. On the other hand, distributed type cameras consist of separate components that can be installed in different locations. This modular approach allows for greater flexibility in terms of camera placement and system configuration. Distributed systems are particularly useful in large or complex environments where multiple areas need to be monitored simultaneously. They allow for the integration of various camera types and technologies, such as thermal imaging or pan-tilt-zoom capabilities, to provide comprehensive coverage of hazardous areas. The choice between integrated and distributed systems often depends on the specific requirements of the application, including factors such as the size of the area to be monitored, the level of detail required, and the environmental conditions present. Both types of cameras are designed to meet stringent safety standards and are built to withstand the harsh conditions typically found in hazardous environments. Manufacturers continue to innovate in this space, developing cameras with enhanced features such as improved image quality, advanced analytics, and wireless connectivity. These advancements are helping to drive the adoption of hazardous area cameras across various industries, as they provide critical insights and enhance safety measures. As technology continues to evolve, the distinction between integrated and distributed systems may become less pronounced, with hybrid solutions offering the best of both worlds. However, the fundamental need for reliable and robust surveillance solutions in hazardous areas remains a key driver of market growth.

Oil and Gas, Chemical Industry, Mining, Others in the Hazardous Area Cameras - Global Market:

Hazardous area cameras play a vital role in several industries, including oil and gas, chemical manufacturing, mining, and others, by providing essential surveillance and monitoring capabilities in environments where safety is a top priority. In the oil and gas industry, these cameras are used to monitor drilling operations, pipelines, and refineries, where the risk of explosions due to flammable gases is high. They help in detecting leaks, monitoring equipment performance, and ensuring compliance with safety regulations. In the chemical industry, hazardous area cameras are employed to oversee production processes, storage facilities, and transportation of hazardous materials. They provide real-time monitoring of critical areas, helping to prevent accidents and ensure the safety of workers and equipment. In mining, these cameras are used to monitor underground operations, where the presence of combustible dust and gases poses significant risks. They help in ensuring the safety of miners by providing visibility in areas that are difficult to access or where human presence is limited. Additionally, hazardous area cameras are used in other industries such as pharmaceuticals, food processing, and manufacturing, where they help in maintaining safety standards and preventing contamination. These cameras are equipped with features such as infrared vision, high-definition imaging, and remote monitoring capabilities, allowing for effective surveillance in challenging environments. As industries continue to prioritize safety and regulatory compliance, the demand for hazardous area cameras is expected to grow, driven by the need for reliable and robust monitoring solutions. The adoption of these cameras is further supported by advancements in technology, which are making them more efficient, cost-effective, and easier to integrate into existing systems.

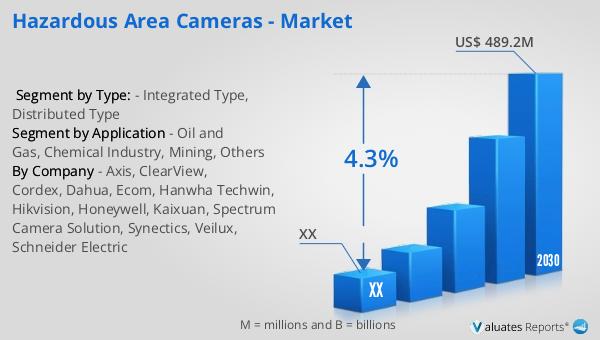

Hazardous Area Cameras - Global Market Outlook:

The global market for hazardous area cameras was valued at approximately $317 million in 2023 and is projected to reach around $489.2 million by 2030, reflecting a compound annual growth rate (CAGR) of 4.3% during the forecast period from 2024 to 2030. This growth is driven by the increasing demand for safety and surveillance solutions in industries such as oil and gas, chemical manufacturing, and mining, where hazardous conditions are prevalent. In North America, the market for hazardous area cameras is also expected to grow significantly, although specific figures for this region were not provided. The growth in this region can be attributed to the presence of a large number of industries that require robust safety measures, as well as the adoption of advanced technologies that enhance the functionality and reliability of these cameras. As industries continue to prioritize safety and regulatory compliance, the demand for hazardous area cameras is expected to increase, driven by the need for reliable and robust monitoring solutions. The adoption of these cameras is further supported by advancements in technology, which are making them more efficient, cost-effective, and easier to integrate into existing systems. Overall, the market outlook for hazardous area cameras is positive, with steady growth anticipated over the coming years as industries continue to invest in safety and surveillance solutions.

| Report Metric | Details |

| Report Name | Hazardous Area Cameras - Market |

| Forecasted market size in 2030 | US$ 489.2 million |

| CAGR | 4.3% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Axis, ClearView, Cordex, Dahua, Ecom, Hanwha Techwin, Hikvision, Honeywell, Kaixuan, Spectrum Camera Solution, Synectics, Veilux, Schneider Electric |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |