What is Food and Apparel Moisture Barrier Film - Global Market?

Food and Apparel Moisture Barrier Film is a specialized material used in packaging to protect products from moisture damage. This film is crucial in maintaining the quality and longevity of food and apparel items by preventing moisture from penetrating the packaging. In the global market, these films are gaining popularity due to their effectiveness in preserving product integrity. They are made from various materials, including plastic and metalized films, which offer different levels of moisture resistance. The demand for these films is driven by the increasing need for efficient packaging solutions in the food and apparel industries. As consumers become more conscious of product quality and shelf life, manufacturers are investing in advanced moisture barrier technologies to meet these expectations. The global market for these films is expanding as more industries recognize their benefits in reducing spoilage and maintaining product freshness. This growth is further supported by technological advancements that enhance the performance and sustainability of moisture barrier films. As a result, the market is witnessing a steady increase in demand, with manufacturers focusing on innovation to cater to diverse industry needs.

Metalized Film, Transparent Film, White Film in the Food and Apparel Moisture Barrier Film - Global Market:

Metalized film, transparent film, and white film are three types of moisture barrier films used in the global market for food and apparel packaging. Metalized films are created by depositing a thin layer of metal, usually aluminum, onto a plastic film. This type of film is highly effective in providing a strong barrier against moisture, oxygen, and light, making it ideal for packaging perishable food items and sensitive apparel products. The reflective surface of metalized films also adds an aesthetic appeal to the packaging, which can enhance brand visibility and consumer attraction. Transparent films, on the other hand, offer a clear view of the product while still providing a moderate level of moisture protection. These films are often used when product visibility is crucial, such as in the packaging of fresh produce or fashion items where the appearance is a key selling point. Transparent films are typically made from materials like polyethylene or polypropylene, which are known for their flexibility and durability. White films are another variant, characterized by their opaque appearance. They are often used when light protection is necessary, in addition to moisture resistance. White films are commonly used in the packaging of dairy products, baked goods, and certain apparel items that may be sensitive to light exposure. Each type of film offers unique benefits and is selected based on the specific requirements of the product being packaged. The choice between metalized, transparent, and white films depends on factors such as the level of moisture protection needed, the importance of product visibility, and the desired aesthetic appeal. As the global market for food and apparel moisture barrier films continues to grow, manufacturers are exploring new materials and technologies to enhance the performance of these films. Innovations such as biodegradable films and films with enhanced barrier properties are gaining traction as companies strive to meet consumer demands for sustainable and effective packaging solutions. The versatility of these films makes them a valuable asset in the packaging industry, catering to a wide range of applications and product types. As a result, the market is witnessing increased competition among manufacturers to develop superior moisture barrier films that offer both functionality and environmental benefits.

Food, Apparel in the Food and Apparel Moisture Barrier Film - Global Market:

The usage of food and apparel moisture barrier films is crucial in preserving the quality and extending the shelf life of products in these industries. In the food sector, these films are used extensively to package a variety of products, including snacks, baked goods, dairy products, and fresh produce. The primary function of these films is to prevent moisture ingress, which can lead to spoilage, mold growth, and a reduction in product quality. By maintaining a controlled environment within the packaging, moisture barrier films help to preserve the taste, texture, and nutritional value of food items. This is particularly important for perishable goods that require a longer shelf life to reach consumers in optimal condition. In addition to moisture protection, these films also provide a barrier against oxygen and light, which can further degrade food quality. In the apparel industry, moisture barrier films are used to protect garments from moisture damage during storage and transportation. This is especially important for clothing items made from delicate fabrics or those that are susceptible to mold and mildew. By preventing moisture penetration, these films help to maintain the appearance and integrity of apparel products, ensuring they reach consumers in pristine condition. The use of moisture barrier films in apparel packaging also helps to reduce the risk of damage caused by environmental factors such as humidity and temperature fluctuations. This is particularly beneficial for high-end fashion items and seasonal clothing that may be stored for extended periods. As the demand for high-quality packaging solutions continues to grow, the use of moisture barrier films in the food and apparel industries is expected to increase. Manufacturers are investing in research and development to create films with enhanced barrier properties and sustainability features. This includes the development of biodegradable films and those made from renewable materials, which align with consumer preferences for environmentally friendly packaging. The versatility and effectiveness of moisture barrier films make them an essential component in the packaging strategies of food and apparel companies worldwide. By providing reliable protection against moisture and other environmental factors, these films help to ensure product quality and customer satisfaction. As a result, the global market for food and apparel moisture barrier films is poised for continued growth, driven by advancements in technology and increasing consumer awareness of packaging quality.

Food and Apparel Moisture Barrier Film - Global Market Outlook:

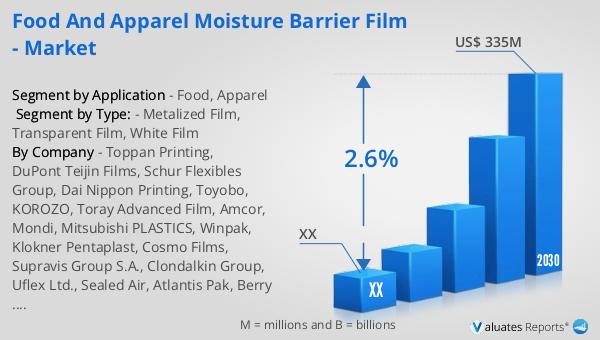

In 2023, the global market for Food and Apparel Moisture Barrier Film was valued at approximately $275.4 million. This market is projected to grow, reaching an estimated size of $335 million by 2030, with a compound annual growth rate (CAGR) of 2.6% during the forecast period from 2024 to 2030. The North American segment of this market also shows promising growth potential. Although specific figures for the North American market in 2023 and 2030 are not provided, it is expected to follow a similar upward trend as the global market. The growth in this region can be attributed to the increasing demand for effective packaging solutions that enhance product shelf life and quality. As consumers become more aware of the importance of packaging in preserving product integrity, manufacturers in North America are likely to invest in advanced moisture barrier technologies. This investment will drive the market forward, ensuring that food and apparel products are protected from moisture damage and other environmental factors. The steady growth of the Food and Apparel Moisture Barrier Film market reflects the ongoing need for innovative packaging solutions that meet the evolving demands of consumers and industries alike.

| Report Metric | Details |

| Report Name | Food and Apparel Moisture Barrier Film - Market |

| Forecasted market size in 2030 | US$ 335 million |

| CAGR | 2.6% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Toppan Printing, DuPont Teijin Films, Schur Flexibles Group, Dai Nippon Printing, Toyobo, KOROZO, Toray Advanced Film, Amcor, Mondi, Mitsubishi PLASTICS, Winpak, Klokner Pentaplast, Cosmo Films, Supravis Group S.A., Clondalkin Group, Uflex Ltd., Sealed Air, Atlantis Pak, Berry Plastics, Innovia Films, VF Verpackungen GmbH, Accredo Packaging, Lietpak |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |