What is Fire Stop Breathing Valve - Global Market?

Fire stop breathing valves are crucial components in various industries, designed to prevent the spread of fire through ventilation systems while allowing necessary airflow. These valves are engineered to close automatically in the event of a fire, thereby stopping the passage of flames and smoke. The global market for fire stop breathing valves is driven by the increasing emphasis on safety regulations and the need for fire prevention measures across industrial sectors. These valves are essential in maintaining the integrity of safety systems, ensuring that fire hazards are contained and do not escalate into more significant threats. The demand for fire stop breathing valves is particularly high in industries where flammable materials are prevalent, such as oil and gas, pharmaceuticals, and manufacturing. As industries continue to prioritize safety and compliance with stringent regulations, the market for these valves is expected to grow, driven by technological advancements and the development of more efficient and reliable valve systems. The global market is characterized by a diverse range of products tailored to meet specific industry needs, with manufacturers focusing on innovation to enhance the performance and reliability of these critical safety components.

Ball Valve Type, Diaphragm Type, Piston Type in the Fire Stop Breathing Valve - Global Market:

Fire stop breathing valves come in various types, each designed to meet specific operational requirements and safety standards. The ball valve type is one of the most common, known for its durability and ability to provide a tight seal. It operates by using a spherical disc to control the flow of air or gas, making it highly effective in preventing the spread of fire. Ball valves are favored for their simplicity and reliability, often used in applications where quick shut-off is essential. The diaphragm type valve, on the other hand, uses a flexible diaphragm to regulate flow. This type is particularly useful in applications where precise control is needed, as the diaphragm can adjust to varying pressure levels. Diaphragm valves are often used in industries where contamination must be minimized, such as pharmaceuticals, due to their ability to provide a clean and leak-proof seal. Piston type valves operate using a piston mechanism to control airflow. These valves are known for their robustness and are typically used in high-pressure applications. The piston type is ideal for environments where the valve must withstand significant pressure changes without compromising its sealing capability. Each type of valve offers unique advantages, and the choice of valve depends on the specific requirements of the application, including factors such as pressure, temperature, and the nature of the materials being handled. In the global market, manufacturers are continually innovating to improve the performance and efficiency of these valves, ensuring they meet the evolving needs of various industries. The development of advanced materials and technologies has led to the creation of valves that are more resistant to wear and corrosion, enhancing their longevity and reliability. As industries continue to evolve, the demand for specialized fire stop breathing valves is expected to increase, driven by the need for enhanced safety measures and compliance with international standards. The global market for these valves is characterized by a wide range of products, each designed to meet the specific needs of different industries, from oil and gas to pharmaceuticals and beyond. Manufacturers are focusing on developing valves that offer superior performance, reliability, and ease of maintenance, ensuring they can meet the stringent demands of modern industrial applications.

Pharmaceutical, Oil and Gas, Generate Electricity, Metals and Mining, Others in the Fire Stop Breathing Valve - Global Market:

Fire stop breathing valves play a vital role in various industries, providing essential safety measures to prevent the spread of fire. In the pharmaceutical industry, these valves are crucial in maintaining a safe environment, as many pharmaceutical processes involve the use of flammable substances. The valves ensure that any potential fire hazards are contained, preventing them from spreading through ventilation systems and causing widespread damage. In the oil and gas industry, fire stop breathing valves are indispensable due to the high risk of fire associated with the handling of flammable gases and liquids. These valves are used to isolate sections of a facility in the event of a fire, preventing the spread of flames and protecting critical infrastructure. In the generation of electricity, fire stop breathing valves are used to safeguard power plants, where the risk of fire is significant due to the presence of combustible materials and high temperatures. These valves help to contain fires, ensuring the safety of personnel and minimizing damage to equipment. In the metals and mining industry, fire stop breathing valves are used to protect facilities from the risk of fire, which can be caused by the presence of flammable dust and gases. These valves are essential in maintaining a safe working environment, preventing the spread of fire and ensuring the safety of workers. In other industries, such as manufacturing and chemical processing, fire stop breathing valves are used to enhance safety measures, providing a reliable means of containing fires and preventing them from spreading through ventilation systems. The global market for fire stop breathing valves is driven by the increasing emphasis on safety and compliance with stringent regulations, with manufacturers focusing on developing innovative solutions to meet the evolving needs of various industries. As industries continue to prioritize safety and efficiency, the demand for fire stop breathing valves is expected to grow, driven by the need for reliable and effective fire prevention measures.

Fire Stop Breathing Valve - Global Market Outlook:

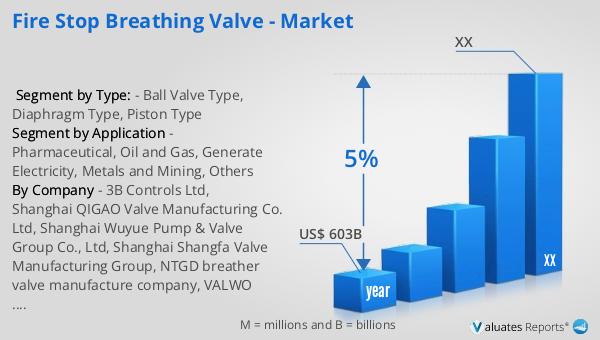

Based on our analysis, the global market for medical devices is projected to reach approximately $603 billion in 2023, with an anticipated growth rate of 5% annually over the next six years.

| Report Metric | Details |

| Report Name | Fire Stop Breathing Valve - Market |

| Accounted market size in year | US$ 603 billion |

| CAGR | 5% |

| Base Year | year |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | 3B Controls Ltd, Shanghai QIGAO Valve Manufacturing Co. Ltd, Shanghai Wuyue Pump & Valve Group Co., Ltd, Shanghai Shangfa Valve Manufacturing Group, NTGD breather valve manufacture company, VALWO s.r.o. company, FLUIDYNE, Yongjia County Yuchen Valve Co., Ltd., Wenzhou Niwei Valve Co., Ltd., Yongjia Zhoutai Petrochemical Equipment Factory |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |