What is EMI Shielding Plastic Compounds - Global Market?

EMI shielding plastic compounds are specialized materials designed to block electromagnetic interference (EMI), which can disrupt electronic devices. These compounds are crucial in ensuring that electronic devices function properly without interference from external electromagnetic fields. The global market for EMI shielding plastic compounds is growing as the demand for electronic devices increases. These compounds are used in various industries, including automotive, telecommunications, and consumer electronics, to protect sensitive electronic components. The compounds are made by incorporating conductive fillers into plastic materials, which then provide the necessary shielding properties. The market is driven by the need for lightweight, cost-effective, and efficient EMI shielding solutions. As technology advances and electronic devices become more complex, the demand for effective EMI shielding solutions continues to rise. This growth is further fueled by the increasing regulatory requirements for electromagnetic compatibility in various industries. The global market for EMI shielding plastic compounds is expected to expand as more industries recognize the importance of protecting their electronic devices from electromagnetic interference.

Thermosetting Materials, Thermoplastic Materials, Others in the EMI Shielding Plastic Compounds - Global Market:

Thermosetting materials, thermoplastic materials, and other types of materials play a significant role in the EMI shielding plastic compounds market. Thermosetting materials are polymers that irreversibly cure to form a rigid structure. They are known for their excellent thermal stability and resistance to deformation under heat, making them ideal for applications requiring durable and heat-resistant EMI shielding. These materials are often used in high-performance applications where long-term stability and reliability are crucial. Thermoplastic materials, on the other hand, are polymers that become pliable or moldable at a certain elevated temperature and solidify upon cooling. They are valued for their versatility, ease of processing, and recyclability. Thermoplastics are widely used in EMI shielding applications due to their ability to be reshaped and reused, which is beneficial for manufacturing processes that require flexibility and cost-effectiveness. Other materials used in EMI shielding plastic compounds include elastomers and composites. Elastomers are rubber-like materials that provide flexibility and resilience, making them suitable for applications where flexibility and impact resistance are important. Composites, which are made by combining two or more different materials, offer a balance of properties that can be tailored to specific EMI shielding requirements. The choice of material depends on the specific application and the desired properties of the EMI shielding solution. Each type of material offers unique advantages and challenges, and the selection process involves considering factors such as thermal stability, mechanical strength, electrical conductivity, and cost. As the demand for EMI shielding solutions continues to grow, manufacturers are exploring new materials and technologies to enhance the performance and efficiency of EMI shielding plastic compounds. This ongoing innovation is essential to meet the evolving needs of various industries and to address the challenges posed by the increasing complexity of electronic devices.

Electronic, Semiconductor, Integrated Circuit, Others in the EMI Shielding Plastic Compounds - Global Market:

EMI shielding plastic compounds are extensively used in various sectors, including electronics, semiconductors, integrated circuits, and others, to protect sensitive components from electromagnetic interference. In the electronics industry, these compounds are crucial for ensuring the proper functioning of devices such as smartphones, tablets, and laptops. As electronic devices become more compact and feature-rich, the need for effective EMI shielding solutions becomes more critical. EMI shielding plastic compounds help prevent interference that can lead to malfunctions or reduced performance in electronic devices. In the semiconductor industry, these compounds are used to protect delicate semiconductor components from electromagnetic interference that can affect their performance and reliability. The increasing demand for high-performance semiconductors in applications such as data centers, automotive electronics, and consumer electronics is driving the need for advanced EMI shielding solutions. Integrated circuits, which are the building blocks of modern electronic devices, also require effective EMI shielding to ensure their proper functioning. EMI shielding plastic compounds are used to protect integrated circuits from external electromagnetic fields that can cause errors or failures. Other industries, such as automotive and telecommunications, also rely on EMI shielding plastic compounds to protect their electronic systems from interference. In the automotive industry, the increasing use of electronic systems for functions such as navigation, entertainment, and safety requires effective EMI shielding solutions to ensure reliable performance. In telecommunications, EMI shielding is essential for maintaining the integrity of communication signals and preventing interference that can disrupt service. As the demand for electronic devices and systems continues to grow, the need for effective EMI shielding solutions will remain a critical consideration for manufacturers across various industries.

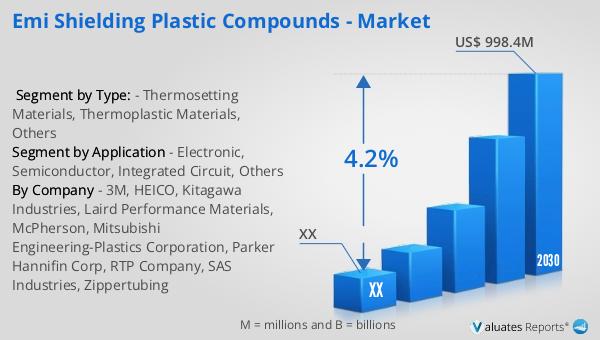

EMI Shielding Plastic Compounds - Global Market Outlook:

The global market for EMI shielding plastic compounds was valued at approximately $730 million in 2023 and is projected to reach an adjusted size of $998.4 million by 2030, reflecting a compound annual growth rate (CAGR) of 4.2% during the forecast period from 2024 to 2030. This growth is driven by the increasing demand for electronic devices and the need for effective EMI shielding solutions across various industries. In North America, the market for EMI shielding plastic compounds was valued at a significant amount in 2023 and is expected to grow steadily through 2030. The region's growth is supported by the presence of major electronic manufacturers and the increasing adoption of advanced technologies in industries such as automotive, telecommunications, and consumer electronics. The demand for lightweight, cost-effective, and efficient EMI shielding solutions is driving innovation and development in the market. As industries continue to evolve and electronic devices become more complex, the need for effective EMI shielding solutions will remain a key focus for manufacturers. The global market for EMI shielding plastic compounds is poised for growth as more industries recognize the importance of protecting their electronic devices from electromagnetic interference.

| Report Metric | Details |

| Report Name | EMI Shielding Plastic Compounds - Market |

| Forecasted market size in 2030 | US$ 998.4 million |

| CAGR | 4.2% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | 3M, HEICO, Kitagawa Industries, Laird Performance Materials, McPherson, Mitsubishi Engineering-Plastics Corporation, Parker Hannifin Corp, RTP Company, SAS Industries, Zippertubing |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |