What is Cured-in-Place Pipe (CIPP) Lining - Global Market?

Cured-in-Place Pipe (CIPP) lining is a trenchless rehabilitation method used to repair existing pipelines. This innovative technology involves inserting a flexible liner coated with resin into the damaged pipe. Once in place, the liner is inflated and cured, typically using hot water, steam, or ultraviolet light, to form a tight-fitting, corrosion-resistant new pipe within the old one. This method is particularly advantageous because it minimizes the need for extensive excavation, reducing both the time and cost associated with traditional pipe replacement. CIPP lining is widely used in various industries, including municipal, industrial, and commercial sectors, to address issues such as leaks, cracks, and structural deterioration in pipelines. Its ability to extend the lifespan of existing infrastructure without significant disruption makes it an attractive solution for maintaining and upgrading aging pipeline systems. As urban areas continue to grow and infrastructure ages, the demand for efficient and cost-effective pipeline rehabilitation methods like CIPP lining is expected to increase, driving growth in the global market. This technology not only offers a sustainable solution by reducing waste and environmental impact but also enhances the reliability and performance of pipeline networks.

Polyester, Vinyl, Epoxy in the Cured-in-Place Pipe (CIPP) Lining - Global Market:

Polyester, vinyl, and epoxy resins are the primary materials used in the Cured-in-Place Pipe (CIPP) lining process, each offering distinct properties that make them suitable for different applications. Polyester resin is the most commonly used material in CIPP lining due to its cost-effectiveness and satisfactory performance in a wide range of conditions. It provides good mechanical strength and chemical resistance, making it suitable for municipal sewer and stormwater applications. Polyester resin is also relatively easy to handle and cure, which contributes to its widespread use in the industry. However, it may not be the best choice for environments with high chemical exposure or extreme temperatures, where more robust materials are required. Vinyl ester resin, on the other hand, offers superior chemical resistance compared to polyester, making it ideal for industrial applications where pipelines are exposed to aggressive chemicals. It also provides better thermal stability, which is crucial in environments with fluctuating temperatures. Although vinyl ester resin is more expensive than polyester, its enhanced properties justify the cost in demanding applications. Epoxy resin is known for its excellent adhesion, mechanical strength, and chemical resistance, making it suitable for a wide range of applications, including potable water pipelines. Its ability to form a strong bond with various substrates ensures a durable and long-lasting repair. Epoxy resin is also less prone to shrinkage during curing, which helps maintain the integrity of the liner. However, it is generally more expensive and requires more precise handling and curing conditions compared to polyester and vinyl ester resins. The choice of resin in CIPP lining depends on several factors, including the specific requirements of the pipeline, environmental conditions, and budget constraints. In the global market, the demand for these resins is influenced by the growing need for pipeline rehabilitation and the increasing awareness of the benefits of trenchless technologies. As industries continue to seek sustainable and efficient solutions for maintaining their infrastructure, the use of polyester, vinyl, and epoxy resins in CIPP lining is expected to grow. Each resin type offers unique advantages that cater to different market needs, ensuring that CIPP lining remains a versatile and effective method for pipeline rehabilitation. The ongoing development of new resin formulations and curing technologies further enhances the performance and applicability of CIPP lining, making it a key player in the global market for pipeline rehabilitation solutions.

Agricultural Industry, Construction Industry, Chemical Industry, Power Industry, Other in the Cured-in-Place Pipe (CIPP) Lining - Global Market:

Cured-in-Place Pipe (CIPP) lining is a versatile technology that finds applications across various industries, including agriculture, construction, chemical, power, and others. In the agricultural industry, CIPP lining is used to rehabilitate irrigation pipelines, ensuring efficient water delivery to crops. The technology's ability to repair pipelines without extensive excavation is particularly beneficial in agricultural settings, where minimizing disruption to the land is crucial. By extending the lifespan of existing irrigation systems, CIPP lining helps farmers maintain productivity and reduce water waste. In the construction industry, CIPP lining is employed to repair and maintain drainage and sewer systems in residential, commercial, and industrial buildings. The technology's trenchless nature allows for quick and cost-effective repairs, minimizing disruption to construction activities and reducing the impact on surrounding infrastructure. This is especially important in urban areas, where space is limited, and traditional excavation methods can be disruptive and costly. The chemical industry benefits from CIPP lining's ability to withstand harsh chemical environments. Pipelines used to transport chemicals are often exposed to corrosive substances, which can lead to leaks and environmental contamination. CIPP lining provides a durable and chemically resistant solution, ensuring the safe and efficient transport of chemicals. This not only helps prevent costly leaks and spills but also enhances the overall safety and reliability of chemical processing facilities. In the power industry, CIPP lining is used to rehabilitate pipelines that transport cooling water, fuel, and other essential fluids. The technology's ability to withstand high temperatures and pressures makes it suitable for power plants and other energy facilities. By maintaining the integrity of these pipelines, CIPP lining helps ensure the efficient operation of power generation systems and reduces the risk of costly downtime. Other industries, such as oil and gas, mining, and food processing, also benefit from the versatility and effectiveness of CIPP lining. In the oil and gas industry, for example, CIPP lining is used to repair pipelines that transport crude oil, natural gas, and refined products. The technology's ability to withstand high pressures and corrosive environments makes it an ideal solution for maintaining the integrity of these critical infrastructure components. In the mining industry, CIPP lining is used to rehabilitate pipelines that transport slurry, water, and other materials, ensuring the efficient operation of mining processes. The food processing industry benefits from CIPP lining's ability to provide a clean and sanitary solution for repairing pipelines that transport food products and ingredients. Overall, the global market for CIPP lining is driven by the technology's ability to provide efficient, cost-effective, and environmentally friendly solutions for pipeline rehabilitation across a wide range of industries. As the demand for sustainable infrastructure solutions continues to grow, CIPP lining is expected to play an increasingly important role in maintaining and upgrading pipeline systems worldwide.

Cured-in-Place Pipe (CIPP) Lining - Global Market Outlook:

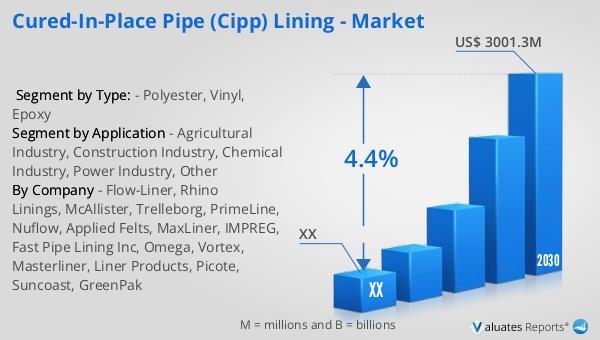

The global market for Cured-in-Place Pipe (CIPP) lining was valued at approximately $2,221 million in 2023. This market is projected to grow significantly, reaching an estimated size of $3,001.3 million by 2030. This growth represents a compound annual growth rate (CAGR) of 4.4% over the forecast period from 2024 to 2030. The North American market is a significant contributor to this growth, driven by the increasing need for pipeline rehabilitation and the adoption of trenchless technologies. The demand for CIPP lining is fueled by the aging infrastructure in many regions, which requires efficient and cost-effective solutions for maintenance and repair. The technology's ability to minimize disruption and reduce costs compared to traditional methods makes it an attractive option for municipalities, industries, and utilities. Additionally, the growing awareness of the environmental benefits of trenchless technologies is expected to further drive the adoption of CIPP lining in the coming years. As industries continue to seek sustainable solutions for maintaining their infrastructure, the global market for CIPP lining is poised for steady growth, offering significant opportunities for manufacturers, contractors, and service providers in the pipeline rehabilitation sector.

| Report Metric | Details |

| Report Name | Cured-in-Place Pipe (CIPP) Lining - Market |

| Forecasted market size in 2030 | US$ 3001.3 million |

| CAGR | 4.4% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Flow-Liner, Rhino Linings, McAllister, Trelleborg, PrimeLine, Nuflow, Applied Felts, MaxLiner, IMPREG, Fast Pipe Lining Inc, Omega, Vortex, Masterliner, Liner Products, Picote, Suncoast, GreenPak |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |