What is Continuous Environmental Monitoring System - Global Market?

Continuous Environmental Monitoring Systems (CEMS) are essential tools in the global market for tracking and managing environmental data. These systems are designed to continuously collect, analyze, and report data on various environmental parameters such as air quality, water quality, and emissions. By providing real-time data, CEMS help industries and governments ensure compliance with environmental regulations, improve operational efficiency, and minimize environmental impact. The global market for these systems is driven by increasing environmental awareness, stringent regulatory requirements, and the need for sustainable industrial practices. As industries strive to reduce their carbon footprint and adhere to environmental standards, the demand for CEMS is expected to grow. These systems are employed across various sectors, including power generation, oil and gas, chemicals, and manufacturing, to monitor pollutants and ensure that emissions remain within permissible limits. The integration of advanced technologies such as IoT and AI in CEMS is further enhancing their capabilities, making them more efficient and user-friendly. Overall, the continuous environmental monitoring system market is poised for significant growth as the world moves towards more sustainable and environmentally responsible practices.

Dry Basis Measurement, Wet Basis Measurement in the Continuous Environmental Monitoring System - Global Market:

In the realm of Continuous Environmental Monitoring Systems, two critical measurement methodologies are Dry Basis Measurement and Wet Basis Measurement. These methods are pivotal in accurately assessing the concentration of pollutants in emissions, which is crucial for regulatory compliance and environmental protection. Dry Basis Measurement refers to the analysis of gas emissions after the removal of moisture content. This method is particularly useful in industries where the presence of water vapor can skew the results of pollutant concentration measurements. By eliminating the moisture, dry basis measurement provides a more precise reading of the actual pollutants present in the emissions. This method is widely used in industries such as power generation and cement manufacturing, where high-temperature processes often result in significant moisture content in emissions. On the other hand, Wet Basis Measurement involves analyzing emissions with the moisture content intact. This approach is beneficial in scenarios where the moisture content itself is a significant factor in the emissions profile, such as in waste incineration and certain chemical processes. Wet basis measurement provides a comprehensive view of the emissions, including both the pollutants and the moisture content, which can be critical for understanding the full environmental impact of a process. Both measurement methods have their unique advantages and are chosen based on the specific requirements of the monitoring application. The choice between dry and wet basis measurement often depends on the regulatory standards applicable to a particular industry, as well as the specific characteristics of the emissions being monitored. In the global market, the demand for both dry and wet basis measurement systems is driven by the need for accurate and reliable data to support environmental compliance and sustainability initiatives. As industries continue to face increasing pressure to reduce their environmental impact, the adoption of advanced measurement technologies is becoming more prevalent. The integration of digital technologies, such as IoT and AI, is further enhancing the capabilities of these measurement systems, enabling more precise and real-time monitoring of emissions. This technological advancement is expected to drive the growth of the continuous environmental monitoring system market, as industries seek to leverage these tools to achieve their environmental goals. Overall, dry and wet basis measurement systems play a crucial role in the global market for continuous environmental monitoring, providing the data necessary to ensure compliance with environmental regulations and support sustainable industrial practices.

Power Generation, Oil & Gas, Chemicals and Fertilizers, Pulp & Paper, Cement Industry, Metal and Mining, Waste Incineration, Others in the Continuous Environmental Monitoring System - Global Market:

Continuous Environmental Monitoring Systems are extensively used across various industries to ensure compliance with environmental regulations and to minimize the environmental impact of industrial activities. In the power generation sector, these systems are crucial for monitoring emissions from power plants, particularly those that burn fossil fuels. By providing real-time data on pollutants such as sulfur dioxide, nitrogen oxides, and particulate matter, CEMS help power plants optimize their operations and reduce emissions. In the oil and gas industry, continuous monitoring systems are used to track emissions from refineries, drilling operations, and transportation activities. These systems help companies identify and address potential environmental risks, ensuring that their operations remain within regulatory limits. The chemicals and fertilizers industry also relies heavily on CEMS to monitor emissions from manufacturing processes. By providing accurate data on pollutants, these systems enable companies to implement effective pollution control measures and improve their environmental performance. In the pulp and paper industry, continuous monitoring systems are used to track emissions from production processes, helping companies reduce their environmental footprint and comply with regulatory requirements. The cement industry, known for its high emissions, uses CEMS to monitor and control pollutants such as carbon dioxide and particulate matter. By providing real-time data, these systems help cement manufacturers optimize their processes and reduce emissions. In the metal and mining industry, continuous monitoring systems are used to track emissions from smelting and refining operations. These systems provide valuable data that helps companies minimize their environmental impact and ensure compliance with environmental regulations. Waste incineration facilities also rely on CEMS to monitor emissions from the incineration process, ensuring that pollutants are kept within permissible limits. Finally, continuous environmental monitoring systems are used in various other industries, including food and beverage, pharmaceuticals, and textiles, to monitor emissions and ensure compliance with environmental standards. Overall, the use of continuous environmental monitoring systems is essential for industries to achieve their environmental goals and maintain compliance with regulatory requirements.

Continuous Environmental Monitoring System - Global Market Outlook:

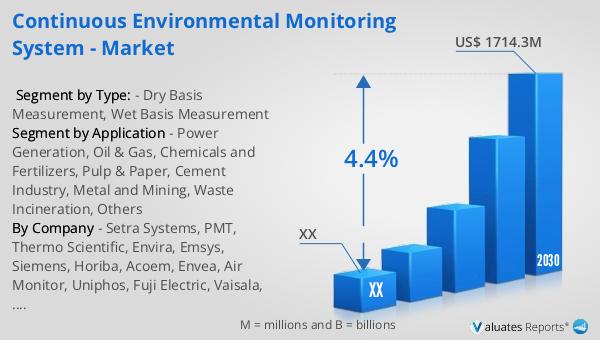

The global market for Continuous Environmental Monitoring Systems was valued at approximately $1,272 million in 2023. It is projected to grow to a revised size of around $1,714.3 million by 2030, reflecting a compound annual growth rate (CAGR) of 4.4% during the forecast period from 2024 to 2030. This growth is driven by increasing environmental awareness, stringent regulatory requirements, and the need for sustainable industrial practices. In North America, the market for Continuous Environmental Monitoring Systems was valued at $ million in 2023 and is expected to reach $ million by 2030, with a CAGR of % during the forecast period from 2024 through 2030. The demand for these systems in North America is fueled by the region's strong regulatory framework and the growing emphasis on environmental sustainability. As industries in North America continue to adopt advanced monitoring technologies to reduce their environmental impact, the market for Continuous Environmental Monitoring Systems is expected to experience significant growth. Overall, the global market for Continuous Environmental Monitoring Systems is poised for substantial expansion as industries worldwide strive to achieve their environmental goals and comply with regulatory requirements.

| Report Metric | Details |

| Report Name | Continuous Environmental Monitoring System - Market |

| Forecasted market size in 2030 | US$ 1714.3 million |

| CAGR | 4.4% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Setra Systems, PMT, Thermo Scientific, Envira, Emsys, Siemens, Horiba, Acoem, Envea, Air Monitor, Uniphos, Fuji Electric, Vaisala, SICK, Ecotech, Ellab, L3Harris, CiSCO, ESC Spectrum |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |