What is Composite EV Battery Enclosures - Global Market?

Composite EV battery enclosures are an essential component in the electric vehicle (EV) industry, providing a protective casing for the battery systems that power these vehicles. These enclosures are crafted from composite materials, which are known for their lightweight and durable properties. The global market for composite EV battery enclosures is experiencing significant growth due to the increasing demand for electric vehicles, driven by environmental concerns and the push for sustainable transportation solutions. These enclosures not only protect the battery from external impacts and harsh environmental conditions but also contribute to the overall efficiency of the vehicle by reducing weight, which in turn enhances the vehicle's range. As the EV market continues to expand, the demand for advanced battery enclosures that offer superior performance and safety features is expected to rise, making this a dynamic and rapidly evolving sector within the automotive industry. The use of composite materials in these enclosures is particularly advantageous as they offer a high strength-to-weight ratio, corrosion resistance, and design flexibility, which are critical factors in the development of next-generation electric vehicles.

Glass Fiber Composites, Carbon Fiber Composites in the Composite EV Battery Enclosures - Global Market:

Glass fiber composites and carbon fiber composites are two primary materials used in the construction of composite EV battery enclosures, each offering distinct advantages. Glass fiber composites are known for their affordability and good mechanical properties, making them a popular choice for many applications. They provide a balance of strength, durability, and cost-effectiveness, which is crucial for manufacturers looking to produce enclosures at scale without compromising on quality. These composites are made by embedding glass fibers within a resin matrix, resulting in a material that is both strong and lightweight. This makes them ideal for use in battery enclosures where weight reduction is a priority, as it directly impacts the vehicle's efficiency and range. On the other hand, carbon fiber composites are renowned for their exceptional strength-to-weight ratio and stiffness. Although more expensive than glass fiber composites, carbon fiber offers superior performance characteristics, making it the material of choice for high-end applications where performance is paramount. The use of carbon fiber in battery enclosures allows for even greater weight savings, which can significantly enhance the performance of electric vehicles by improving acceleration, handling, and energy efficiency. Additionally, carbon fiber composites offer excellent thermal and electrical insulation properties, which are critical for maintaining the safety and reliability of EV battery systems. As the demand for electric vehicles continues to grow, the choice between glass fiber and carbon fiber composites will largely depend on the specific requirements of the vehicle and the manufacturer's priorities in terms of cost, performance, and sustainability. Both materials play a crucial role in the development of advanced battery enclosures that meet the evolving needs of the global EV market.

Battery Electric Vehicle, Hybrid Electric Vehicle in the Composite EV Battery Enclosures - Global Market:

Composite EV battery enclosures are utilized in both battery electric vehicles (BEVs) and hybrid electric vehicles (HEVs), serving as a critical component in ensuring the safety and efficiency of these vehicles. In battery electric vehicles, which rely entirely on electric power, the battery enclosure must provide robust protection against external impacts, thermal management, and environmental factors such as moisture and dust. The use of composite materials in these enclosures offers significant advantages, including weight reduction, which is crucial for maximizing the vehicle's range and performance. By reducing the overall weight of the vehicle, composite enclosures help improve energy efficiency, allowing BEVs to travel longer distances on a single charge. In hybrid electric vehicles, which combine an internal combustion engine with an electric propulsion system, the battery enclosure plays a similar role in protecting the battery pack. However, the requirements for HEV battery enclosures may differ slightly due to the presence of both electric and combustion components. Composite materials are particularly beneficial in this context, as they provide excellent thermal insulation, helping to maintain optimal battery temperatures and prevent overheating. This is especially important in HEVs, where the battery system is subjected to varying temperature conditions due to the operation of the internal combustion engine. Furthermore, the design flexibility offered by composite materials allows manufacturers to create custom enclosures that fit the specific dimensions and configurations of different vehicle models, ensuring a perfect fit and optimal performance. As the automotive industry continues to shift towards electrification, the use of composite EV battery enclosures in both BEVs and HEVs is expected to grow, driven by the need for lightweight, durable, and efficient solutions that enhance vehicle performance and safety.

Composite EV Battery Enclosures - Global Market Outlook:

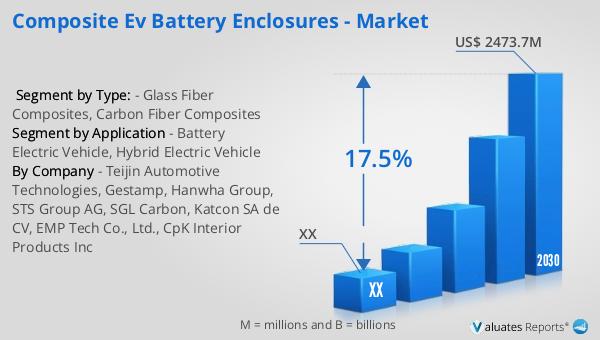

The global market for composite EV battery enclosures was valued at approximately $800 million in 2023, with projections indicating a significant increase to around $2,473.7 million by 2030. This growth represents a compound annual growth rate (CAGR) of 17.5% during the forecast period from 2024 to 2030. The North American market, in particular, is expected to see substantial growth, although specific figures for this region were not provided. The increasing adoption of electric vehicles, coupled with advancements in composite materials technology, is driving this market expansion. As manufacturers seek to improve the performance and safety of EVs, the demand for high-quality battery enclosures is rising. Composite materials, with their lightweight and durable properties, are becoming the preferred choice for these enclosures, offering significant advantages over traditional materials. This market outlook highlights the dynamic nature of the composite EV battery enclosures sector, as it continues to evolve in response to the growing demand for sustainable transportation solutions. The projected growth underscores the importance of innovation and investment in this field, as manufacturers strive to meet the needs of an expanding global market for electric vehicles.

| Report Metric | Details |

| Report Name | Composite EV Battery Enclosures - Market |

| Forecasted market size in 2030 | US$ 2473.7 million |

| CAGR | 17.5% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Teijin Automotive Technologies, Gestamp, Hanwha Group, STS Group AG, SGL Carbon, Katcon SA de CV, EMP Tech Co., Ltd., CpK Interior Products Inc |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |