What is Composite Aluminum Honeycomb Panel - Global Market?

Composite aluminum honeycomb panels are a type of advanced material that has gained significant traction in the global market due to their unique structural properties and versatile applications. These panels are composed of two thin layers of aluminum enclosing a honeycomb core, which is typically made from aluminum as well. This structure provides an excellent strength-to-weight ratio, making the panels both lightweight and incredibly strong. The honeycomb design mimics the natural structure found in beehives, which is known for its efficiency and durability. These panels are used in various industries, including construction, transportation, and aerospace, due to their ability to withstand high stress while remaining lightweight. They also offer excellent thermal and acoustic insulation, corrosion resistance, and fire retardancy, making them suitable for a wide range of environments and applications. As industries continue to seek materials that offer both performance and sustainability, the demand for composite aluminum honeycomb panels is expected to grow, driven by their ability to meet these needs effectively. The global market for these panels is expanding as more sectors recognize their benefits, leading to increased research and development to enhance their properties and applications further.

10mm, 15mm, 20mm, 25mm, 30mm in the Composite Aluminum Honeycomb Panel - Global Market:

When discussing the various thicknesses of composite aluminum honeycomb panels, such as 10mm, 15mm, 20mm, 25mm, and 30mm, it's essential to understand how each thickness serves different purposes and applications in the global market. The 10mm panels are typically used in applications where weight savings are crucial, and the load requirements are relatively low. These panels are often found in interior applications, such as partitions and ceilings, where their lightweight nature helps reduce the overall weight of structures without compromising on strength. Moving up to 15mm panels, these are slightly thicker and offer enhanced strength and rigidity, making them suitable for more demanding applications, such as lightweight furniture and certain automotive components. The 20mm panels strike a balance between weight and strength, making them ideal for use in areas where moderate load-bearing capacity is required, such as in some architectural facades and cladding systems. As we progress to 25mm panels, the increased thickness provides even greater strength and durability, making them suitable for more structural applications, including flooring systems and certain types of transportation infrastructure. Finally, the 30mm panels are the thickest and offer the highest strength and load-bearing capacity, making them ideal for heavy-duty applications such as in the aerospace industry, where they can be used in the construction of aircraft floors and other critical components. Each thickness of composite aluminum honeycomb panel offers unique benefits and is chosen based on the specific requirements of the application, balancing factors such as weight, strength, and cost. As the global market for these panels continues to grow, manufacturers are likely to develop new variations and enhancements to meet the evolving needs of different industries, further expanding the range of applications for these versatile materials.

Curtain Wall, Car and Boat Decoration, Rail Transit, Aviation, Others in the Composite Aluminum Honeycomb Panel - Global Market:

Composite aluminum honeycomb panels find extensive usage across various sectors due to their unique properties, making them a preferred choice for applications such as curtain walls, car and boat decoration, rail transit, aviation, and more. In the realm of curtain walls, these panels offer an excellent combination of lightweight and high strength, which is crucial for modern architectural designs that emphasize large, open spaces with minimal structural support. The panels provide excellent thermal insulation and weather resistance, making them ideal for use in building exteriors where energy efficiency and durability are paramount. In car and boat decoration, the panels are used to create lightweight yet strong components that enhance the aesthetic appeal and performance of vehicles. Their corrosion resistance and ability to withstand harsh environmental conditions make them suitable for both interior and exterior applications in the automotive and marine industries. In rail transit, composite aluminum honeycomb panels are used to construct lightweight yet robust components that contribute to the overall efficiency and safety of trains. Their fire retardant properties and acoustic insulation capabilities make them ideal for use in passenger compartments and other critical areas. In the aviation industry, these panels are indispensable due to their high strength-to-weight ratio, which is essential for reducing the overall weight of aircraft and improving fuel efficiency. They are used in various parts of the aircraft, including floors, walls, and partitions, where their lightweight nature helps enhance performance without compromising safety. Beyond these specific applications, composite aluminum honeycomb panels are also used in other areas such as signage, clean rooms, and even furniture, where their unique properties offer significant advantages over traditional materials. As industries continue to prioritize sustainability and efficiency, the demand for these panels is expected to grow, driven by their ability to meet the stringent requirements of modern applications.

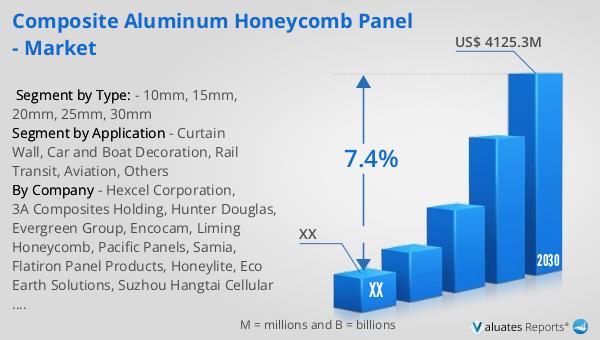

Composite Aluminum Honeycomb Panel - Global Market Outlook:

The global market outlook for composite aluminum honeycomb panels indicates a promising future, with the market valued at approximately US$ 2,514 million in 2023. This market is projected to expand significantly, reaching an estimated size of US$ 4,125.3 million by 2030, reflecting a compound annual growth rate (CAGR) of 7.4% during the forecast period from 2024 to 2030. This growth is driven by the increasing demand for lightweight and durable materials across various industries, including construction, transportation, and aerospace. In North America, the market for composite aluminum honeycomb panels is also expected to grow, although specific figures for this region were not provided. The anticipated growth in this region can be attributed to the rising adoption of these panels in sectors such as automotive and construction, where their unique properties offer significant advantages over traditional materials. As industries continue to seek innovative solutions to enhance performance and sustainability, the demand for composite aluminum honeycomb panels is likely to increase, further driving market growth. The global market's expansion is supported by ongoing research and development efforts aimed at improving the properties and applications of these panels, ensuring they remain a competitive choice for modern applications.

| Report Metric | Details |

| Report Name | Composite Aluminum Honeycomb Panel - Market |

| Forecasted market size in 2030 | US$ 4125.3 million |

| CAGR | 7.4% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Hexcel Corporation, 3A Composites Holding, Hunter Douglas, Evergreen Group, Encocam, Liming Honeycomb, Pacific Panels, Samia, Flatiron Panel Products, Honeylite, Eco Earth Solutions, Suzhou Hangtai Cellular Technology, Guang Zhou KLCC Aluminum |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |