What is Aluminum Alloy Battery Tray - Global Market?

Aluminum alloy battery trays are a crucial component in the automotive industry, particularly in electric and hybrid vehicles. These trays are designed to house and protect the battery packs that power these vehicles. The global market for aluminum alloy battery trays is expanding rapidly due to the increasing demand for electric vehicles (EVs) and hybrid vehicles. Aluminum is favored for its lightweight properties, which help improve the overall efficiency and range of EVs. Additionally, aluminum offers excellent corrosion resistance and thermal conductivity, making it an ideal material for battery trays that need to withstand various environmental conditions. The market is driven by advancements in battery technology and the growing emphasis on reducing vehicle weight to enhance fuel efficiency and reduce emissions. As more countries implement stringent regulations to curb carbon emissions, the demand for aluminum alloy battery trays is expected to rise, further propelling the market's growth. Manufacturers are focusing on developing innovative designs and production techniques to meet the evolving needs of the automotive industry, ensuring that aluminum alloy battery trays remain a vital component in the transition towards cleaner and more sustainable transportation solutions.

Die-cast Aluminum Tray, Extruded Aluminum Tray in the Aluminum Alloy Battery Tray - Global Market:

In the realm of aluminum alloy battery trays, two prominent types are the die-cast aluminum tray and the extruded aluminum tray. Die-cast aluminum trays are manufactured using a process where molten aluminum is injected into a mold under high pressure. This method allows for the creation of complex shapes with high precision and excellent surface finish. Die-cast trays are known for their strength and durability, making them suitable for applications that require robust performance. They are often used in scenarios where the battery tray needs to support significant weight or endure harsh conditions. On the other hand, extruded aluminum trays are produced by forcing aluminum through a die to create long, continuous shapes. This process results in trays that are lightweight yet strong, with excellent dimensional accuracy. Extruded trays are typically used in applications where weight reduction is a priority, such as in electric vehicles where maximizing range is crucial. Both die-cast and extruded aluminum trays offer unique advantages, and the choice between them depends on specific requirements such as weight, strength, and cost considerations. As the global market for aluminum alloy battery trays continues to grow, manufacturers are investing in research and development to enhance the properties of these trays, ensuring they meet the evolving demands of the automotive industry. Innovations in materials and production techniques are expected to further improve the performance and cost-effectiveness of both die-cast and extruded aluminum trays, solidifying their position as essential components in the future of transportation.

Pure Electric Vehicle, Hybrid Vehicle in the Aluminum Alloy Battery Tray - Global Market:

The usage of aluminum alloy battery trays in pure electric vehicles (EVs) and hybrid vehicles is pivotal to the performance and efficiency of these vehicles. In pure electric vehicles, the battery tray serves as the backbone of the vehicle's power system, housing the battery cells that provide the energy needed to drive the electric motor. The lightweight nature of aluminum helps reduce the overall weight of the vehicle, which is crucial for maximizing the range of EVs. A lighter vehicle requires less energy to move, allowing for longer distances to be traveled on a single charge. Additionally, aluminum's excellent thermal conductivity helps dissipate heat generated by the battery cells, preventing overheating and ensuring optimal performance. In hybrid vehicles, which combine an internal combustion engine with an electric motor, aluminum alloy battery trays play a similar role in housing and protecting the battery pack. The use of aluminum helps improve fuel efficiency by reducing the weight of the vehicle, allowing the hybrid system to operate more effectively. As the automotive industry continues to shift towards electrification, the demand for aluminum alloy battery trays in both pure electric and hybrid vehicles is expected to increase. Manufacturers are focusing on developing advanced designs that enhance the safety, efficiency, and longevity of these trays, ensuring they meet the rigorous demands of modern vehicles. The integration of aluminum alloy battery trays in EVs and hybrid vehicles is a testament to the material's versatility and its critical role in the future of sustainable transportation.

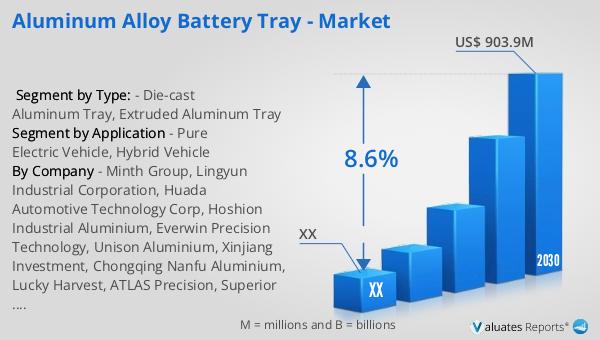

Aluminum Alloy Battery Tray - Global Market Outlook:

The global market for aluminum alloy battery trays was valued at approximately $512 million in 2023. It is projected to grow significantly, reaching an estimated size of $903.9 million by 2030, with a compound annual growth rate (CAGR) of 8.6% during the forecast period from 2024 to 2030. This growth is largely driven by the increasing adoption of electric and hybrid vehicles worldwide. Currently, over 90% of the world's automobiles are concentrated in Asia, Europe, and North America. Asia leads in automobile production, accounting for 56% of the global output, followed by Europe at 20% and North America at 16%. The concentration of automobile production in these regions highlights the significant role they play in the global automotive industry. As these regions continue to invest in electric vehicle infrastructure and technology, the demand for aluminum alloy battery trays is expected to rise. The market's growth is further supported by the ongoing shift towards sustainable transportation solutions and the implementation of stringent emissions regulations. As a result, manufacturers are focusing on developing innovative and cost-effective solutions to meet the growing demand for aluminum alloy battery trays, ensuring they remain a key component in the future of the automotive industry.

| Report Metric | Details |

| Report Name | Aluminum Alloy Battery Tray - Market |

| Forecasted market size in 2030 | US$ 903.9 million |

| CAGR | 8.6% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Minth Group, Lingyun Industrial Corporation, Huada Automotive Technology Corp, Hoshion Industrial Aluminium, Everwin Precision Technology, Unison Aluminium, Xinjiang Investment, Chongqing Nanfu Aluminium, Lucky Harvest, ATLAS Precision, Superior Die Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |