What is Automated Probe Systems - Global Market?

Automated Probe Systems are essential tools in the semiconductor industry, playing a crucial role in testing and evaluating chips and devices. These systems are designed to automatically position and make contact with semiconductor wafers or devices under test, enabling precise measurements and assessments. The global market for Automated Probe Systems is a dynamic and evolving sector, driven by the increasing demand for semiconductors across various industries such as consumer electronics, automotive, and telecommunications. As technology advances, the need for more sophisticated and efficient testing solutions grows, pushing the development and adoption of automated probe systems. These systems offer significant advantages, including improved accuracy, speed, and reliability in testing processes, which are critical for ensuring the quality and performance of semiconductor products. The market is characterized by continuous innovation, with manufacturers striving to enhance the capabilities of these systems to meet the ever-growing demands of the semiconductor industry. As a result, the Automated Probe Systems market is poised for substantial growth, reflecting the broader trends in the semiconductor sector and the increasing complexity of electronic devices.

Semi-Automated Probe Stations, Fully-Automated Probe Stations in the Automated Probe Systems - Global Market:

Semi-Automated Probe Stations and Fully-Automated Probe Stations are two key segments within the Automated Probe Systems market, each offering distinct features and benefits tailored to different testing needs. Semi-Automated Probe Stations are designed to provide a balance between manual control and automation, allowing operators to perform precise testing with some level of human intervention. These stations are typically used in environments where flexibility and customization are important, such as research and development labs or small-scale production facilities. They offer the advantage of being more cost-effective compared to fully automated systems, making them an attractive option for organizations with budget constraints or those that require a high degree of adaptability in their testing processes. On the other hand, Fully-Automated Probe Stations are engineered for high-volume production environments where speed, efficiency, and consistency are paramount. These systems are capable of performing complex testing procedures with minimal human intervention, significantly reducing the time and labor required for testing. Fully-Automated Probe Stations are equipped with advanced features such as robotic arms, automated wafer handling, and sophisticated software algorithms that enable them to perform intricate testing tasks with high precision and repeatability. This makes them ideal for large-scale manufacturing operations where throughput and accuracy are critical. The choice between Semi-Automated and Fully-Automated Probe Stations depends largely on the specific requirements of the testing environment, including factors such as the volume of testing, the complexity of the devices being tested, and the available budget. Both types of stations play a vital role in the semiconductor testing process, contributing to the overall efficiency and effectiveness of the production cycle. As the demand for semiconductors continues to rise, driven by advancements in technology and the proliferation of electronic devices, the market for both Semi-Automated and Fully-Automated Probe Stations is expected to grow, reflecting the increasing need for reliable and efficient testing solutions in the semiconductor industry.

IDMs, OSAT, Research Institute, Others in the Automated Probe Systems - Global Market:

Automated Probe Systems are utilized across various sectors, including Integrated Device Manufacturers (IDMs), Outsourced Semiconductor Assembly and Test (OSAT) companies, research institutes, and other industries that require precise testing and evaluation of semiconductor devices. In the IDM sector, Automated Probe Systems are critical for ensuring the quality and performance of semiconductor products throughout the manufacturing process. IDMs rely on these systems to conduct thorough testing and validation of chips and devices, enabling them to maintain high standards of quality and reliability. The use of Automated Probe Systems in IDMs helps to streamline production processes, reduce defects, and improve overall product performance, which is essential for maintaining competitiveness in the semiconductor market. OSAT companies, which specialize in providing assembly and testing services for semiconductor manufacturers, also benefit significantly from Automated Probe Systems. These systems enable OSAT companies to offer comprehensive testing solutions to their clients, ensuring that semiconductor devices meet the required specifications and performance standards. By leveraging Automated Probe Systems, OSAT companies can enhance their service offerings, improve testing efficiency, and reduce turnaround times, ultimately delivering greater value to their customers. Research institutes, which focus on advancing semiconductor technology and developing new applications, utilize Automated Probe Systems to conduct experiments and validate their findings. These systems provide researchers with the tools needed to perform precise measurements and analyses, facilitating the development of innovative semiconductor solutions. In addition to IDMs, OSAT companies, and research institutes, Automated Probe Systems are also used in other industries that require accurate testing and evaluation of electronic components. This includes sectors such as automotive, telecommunications, and consumer electronics, where the performance and reliability of semiconductor devices are critical to the success of their products. Overall, the widespread use of Automated Probe Systems across various sectors underscores their importance in the semiconductor industry and highlights the growing demand for advanced testing solutions that can keep pace with the rapid advancements in technology.

Automated Probe Systems - Global Market Outlook:

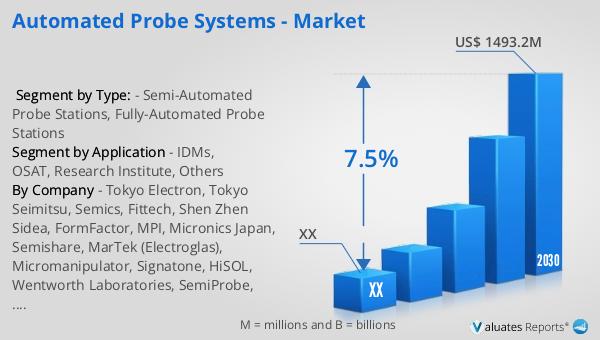

The global market for Automated Probe Systems was valued at approximately $903 million in 2023, with projections indicating a significant increase to around $1,493.2 million by 2030. This growth is expected to occur at a compound annual growth rate (CAGR) of 7.5% from 2024 to 2030. Automated Probe Systems are indispensable in the semiconductor industry, serving as vital tools for testing and evaluating chips and devices. These systems are designed to enhance the efficiency and accuracy of testing processes, which are crucial for ensuring the quality and performance of semiconductor products. The increasing complexity of electronic devices and the growing demand for semiconductors across various industries are key drivers of the market's expansion. As technology continues to advance, the need for more sophisticated and efficient testing solutions becomes increasingly important, fueling the development and adoption of Automated Probe Systems. The market is characterized by continuous innovation, with manufacturers striving to enhance the capabilities of these systems to meet the evolving demands of the semiconductor industry. As a result, the Automated Probe Systems market is poised for substantial growth, reflecting the broader trends in the semiconductor sector and the increasing complexity of electronic devices.

| Report Metric | Details |

| Report Name | Automated Probe Systems - Market |

| Forecasted market size in 2030 | US$ 1493.2 million |

| CAGR | 7.5% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Tokyo Electron, Tokyo Seimitsu, Semics, Fittech, Shen Zhen Sidea, FormFactor, MPI, Micronics Japan, Semishare, MarTek (Electroglas), Micromanipulator, Signatone, HiSOL, Wentworth Laboratories, SemiProbe, APOLLOWAVE, MicroXact, KeithLink Technology, Shenzhen Cindbest Technology, ESDEMC Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |