What is Global Vacuum Carburizing Furnaces Market?

The Global Vacuum Carburizing Furnaces Market refers to the worldwide industry focused on the production, distribution, and utilization of vacuum carburizing furnaces. These specialized furnaces are used in the heat treatment process to harden the surface of metal parts, enhancing their durability and performance. The process involves heating the metal in a vacuum environment and introducing a carbon-rich gas, which diffuses into the metal's surface. This market is driven by the demand for high-performance materials in various industries, including automotive, aerospace, and manufacturing. The growth of this market is influenced by technological advancements, increasing industrialization, and the need for efficient and reliable heat treatment solutions. Companies in this market are continuously innovating to improve furnace efficiency, reduce energy consumption, and meet the stringent quality standards required by different industries. The market is also characterized by a competitive landscape with several key players striving to expand their market share through strategic partnerships, mergers, and acquisitions.

Single-Chamber, Double-Chamber, Multi-Chamber in the Global Vacuum Carburizing Furnaces Market:

Single-Chamber, Double-Chamber, and Multi-Chamber vacuum carburizing furnaces are different types of furnaces used in the Global Vacuum Carburizing Furnaces Market, each with unique features and applications. Single-Chamber furnaces are the simplest type, consisting of one chamber where both heating and carburizing processes occur. These furnaces are typically used for smaller-scale operations or for parts that do not require complex treatment cycles. They are cost-effective and easier to maintain, making them suitable for small to medium-sized enterprises. However, their limited capacity and slower processing times can be a drawback for larger industrial applications. Double-Chamber furnaces, on the other hand, have two separate chambers: one for heating and another for carburizing. This separation allows for more precise control over the treatment process, resulting in higher quality and more consistent results. Double-Chamber furnaces are ideal for medium to large-scale operations where efficiency and precision are critical. They offer faster processing times compared to Single-Chamber furnaces and can handle larger volumes of parts. Multi-Chamber furnaces take this a step further by incorporating multiple chambers for different stages of the heat treatment process, such as pre-heating, carburizing, and quenching. These furnaces are designed for high-volume production and are commonly used in industries that require large-scale, continuous operations. The multiple chambers allow for simultaneous processing of different batches, significantly increasing throughput and reducing cycle times. Multi-Chamber furnaces also offer advanced features such as automated loading and unloading systems, real-time monitoring, and precise control over temperature and gas flow. This makes them highly efficient and capable of meeting the stringent quality standards of industries like automotive and aerospace. Despite their higher initial cost, the long-term benefits of increased productivity and reduced operational costs make Multi-Chamber furnaces a valuable investment for large-scale manufacturers. Each type of furnace has its own set of advantages and limitations, and the choice between them depends on factors such as production volume, budget, and specific application requirements. Companies in the Global Vacuum Carburizing Furnaces Market must carefully evaluate these factors to select the most suitable furnace type for their needs.

Automotive, Tool & Die, Others in the Global Vacuum Carburizing Furnaces Market:

The Global Vacuum Carburizing Furnaces Market finds extensive usage in various industries, including automotive, tool & die, and others. In the automotive industry, vacuum carburizing furnaces are essential for manufacturing high-performance components such as gears, crankshafts, and camshafts. These components require a hard, wear-resistant surface to withstand the high stresses and friction encountered during operation. Vacuum carburizing provides a uniform and controlled hardening process, ensuring that automotive parts meet the stringent quality and durability standards required by the industry. The ability to produce lightweight yet strong components also contributes to improved fuel efficiency and overall vehicle performance. In the tool & die industry, vacuum carburizing furnaces are used to enhance the hardness and wear resistance of various tools and dies. These include cutting tools, molds, and stamping dies, which are subjected to extreme conditions during manufacturing processes. The precise control offered by vacuum carburizing ensures that these tools maintain their sharpness and dimensional accuracy, leading to longer tool life and reduced downtime. This is particularly important in high-precision industries such as aerospace and electronics, where even minor deviations can result in significant quality issues. Beyond automotive and tool & die, vacuum carburizing furnaces are also utilized in other sectors such as aerospace, medical devices, and energy. In the aerospace industry, components like turbine blades, landing gear, and fasteners require exceptional strength and fatigue resistance. Vacuum carburizing furnaces provide the necessary treatment to achieve these properties, ensuring the reliability and safety of aerospace components. In the medical device industry, vacuum carburizing is used to harden surgical instruments and implants, enhancing their durability and resistance to wear and corrosion. This is crucial for maintaining the performance and longevity of medical devices, which directly impact patient outcomes. The energy sector also benefits from vacuum carburizing furnaces, particularly in the production of components for power generation and oil & gas exploration. These components, such as drill bits, valves, and turbine parts, operate in harsh environments and require superior hardness and wear resistance. Vacuum carburizing furnaces provide the necessary treatment to extend the service life of these components, reducing maintenance costs and improving operational efficiency. Overall, the versatility and effectiveness of vacuum carburizing furnaces make them indispensable across a wide range of industries, driving the growth and development of the Global Vacuum Carburizing Furnaces Market.

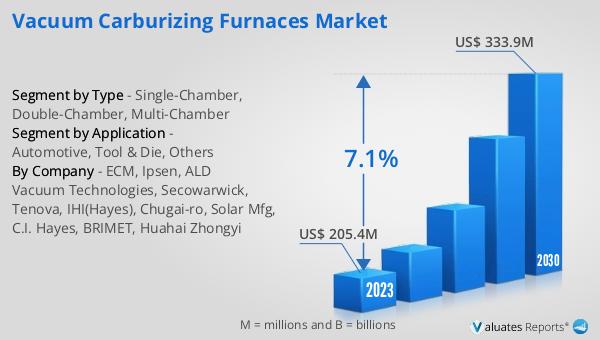

Global Vacuum Carburizing Furnaces Market Outlook:

The global Vacuum Carburizing Furnaces market is anticipated to grow significantly, reaching an estimated value of US$ 333.9 million by 2030, up from US$ 221.2 million in 2024, with a compound annual growth rate (CAGR) of 7.1% during the period from 2024 to 2030. The Asia Pacific region dominates the market, accounting for the largest share at 52% of global sales. Europe follows with a 23% share, while North America holds 18% of the market. Other regions contribute smaller portions to the overall market. ECM stands out as the leading enterprise in this sector, capturing 23% of the global revenue share. The top five manufacturers collectively account for 74% of the market, indicating a highly competitive landscape with a few key players holding significant influence.

| Report Metric | Details |

| Report Name | Vacuum Carburizing Furnaces Market |

| Accounted market size in 2024 | an estimated US$ 221.2 million |

| Forecasted market size in 2030 | US$ 333.9 million |

| CAGR | 7.1% |

| Base Year | 2024 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | ECM, Ipsen, ALD Vacuum Technologies, Secowarwick, Tenova, IHI(Hayes), Chugai-ro, Solar Mfg, C.I. Hayes, BRIMET, Huahai Zhongyi |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |