What is Global Tungsten Carbide Market?

The Global Tungsten Carbide Market refers to the worldwide industry involved in the production, distribution, and utilization of tungsten carbide. Tungsten carbide is a chemical compound composed of tungsten and carbon atoms in equal parts. It is known for its exceptional hardness, wear resistance, and ability to withstand high temperatures, making it a valuable material in various industrial applications. The market encompasses a wide range of products, including cutting tools, machine tools, dies, punches, and other components that benefit from the unique properties of tungsten carbide. The demand for tungsten carbide is driven by its extensive use in industries such as automotive, aerospace, mining, and manufacturing, where durability and performance are critical. The market is characterized by continuous innovation and development to meet the evolving needs of these industries, ensuring that tungsten carbide remains a vital material in modern manufacturing and engineering processes.

Grain Sizes Up to 1 µm, Grain Sizes 1-10 µm, Grain Sizes Above 10 µm, Others in the Global Tungsten Carbide Market:

In the Global Tungsten Carbide Market, grain sizes play a crucial role in determining the properties and applications of tungsten carbide products. Grain sizes up to 1 µm, also known as submicron grades, are characterized by their extremely fine grains. These fine grains provide superior hardness and wear resistance, making them ideal for applications requiring high precision and durability, such as cutting tools and wear parts. Submicron grades are particularly effective in machining hard materials and achieving fine finishes. Grain sizes ranging from 1 to 10 µm, often referred to as medium grain sizes, offer a balance between hardness and toughness. These grades are versatile and widely used in various applications, including machine tools, components, and dies. They provide good wear resistance while maintaining sufficient toughness to withstand impact and shock loads. Grain sizes above 10 µm, known as coarse grain sizes, are characterized by their larger grains, which enhance toughness and impact resistance. These grades are suitable for heavy-duty applications where toughness is more critical than hardness, such as mining tools and construction equipment. Coarse grain sizes are also used in applications where thermal stability is essential, as they can better withstand high temperatures without significant degradation. Other grain sizes, which may fall outside these defined ranges, are tailored for specific applications that require unique combinations of hardness, toughness, and wear resistance. The choice of grain size depends on the specific requirements of the application, and manufacturers often customize the grain size to optimize performance. The ability to manipulate grain size allows for the development of tungsten carbide products that meet the diverse needs of various industries, ensuring that the material remains a versatile and indispensable component in modern manufacturing and engineering.

Machine Tools and Components, Cutting Tools, Dies and Punches, Others in the Global Tungsten Carbide Market:

The Global Tungsten Carbide Market finds extensive usage in several key areas, including machine tools and components, cutting tools, dies and punches, and other specialized applications. In the realm of machine tools and components, tungsten carbide is prized for its exceptional hardness and wear resistance. It is used to manufacture various machine parts, such as bearings, bushings, and valve seats, which require high durability and the ability to withstand harsh operating conditions. Tungsten carbide components ensure long-lasting performance and reduce the need for frequent maintenance and replacements, thereby enhancing the efficiency and reliability of machinery. In the field of cutting tools, tungsten carbide is a preferred material due to its ability to maintain sharp cutting edges and resist wear. It is used to produce a wide range of cutting tools, including drills, end mills, and inserts, which are essential for machining operations in industries such as automotive, aerospace, and metalworking. Tungsten carbide cutting tools enable precise and efficient material removal, resulting in high-quality finished products and increased productivity. Dies and punches, which are critical components in metal forming and stamping processes, also benefit from the properties of tungsten carbide. The material's hardness and wear resistance make it ideal for producing dies and punches that can withstand the high pressures and repetitive impacts involved in shaping and cutting metal sheets. Tungsten carbide dies and punches ensure consistent performance and extended tool life, reducing downtime and production costs. Additionally, tungsten carbide is used in various other applications, such as mining tools, construction equipment, and wear-resistant coatings. In mining, tungsten carbide is used to manufacture drill bits and cutting tools that can penetrate hard rock formations and withstand abrasive conditions. In construction, it is used in tools and equipment that require high durability and resistance to wear, such as road milling tools and concrete cutting blades. Tungsten carbide coatings are applied to surfaces that need enhanced wear resistance and protection against corrosion, extending the lifespan of components in demanding environments. The versatility and superior performance of tungsten carbide make it an indispensable material in these diverse applications, driving its demand in the global market.

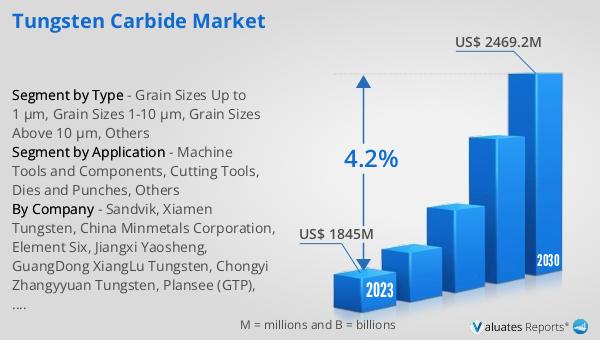

Global Tungsten Carbide Market Outlook:

The global Tungsten Carbide market is anticipated to grow from an estimated US$ 1929.1 million in 2024 to reach US$ 2469.2 million by 2030, reflecting a compound annual growth rate (CAGR) of 4.2% during the forecast period from 2024 to 2030. The market is dominated by the top three players, who collectively hold approximately 34% of the global market share. Among the various types of tungsten carbide, grain sizes ranging from 1 to 10 µm are the most prevalent, accounting for about 45% of the market share. This particular grain size is favored due to its balanced properties of hardness and toughness, making it suitable for a wide range of industrial applications. The market's growth is driven by the increasing demand for high-performance materials in industries such as automotive, aerospace, mining, and manufacturing, where tungsten carbide's exceptional hardness, wear resistance, and thermal stability are highly valued. The continuous innovation and development of new tungsten carbide products tailored to meet specific industry requirements further contribute to the market's expansion. As industries continue to seek materials that enhance efficiency, durability, and performance, the global Tungsten Carbide market is poised to maintain its upward trajectory, supported by the strong presence of leading market players and the widespread adoption of tungsten carbide products across various sectors.

| Report Metric | Details |

| Report Name | Tungsten Carbide Market |

| Accounted market size in 2024 | an estimated US$ 1929.1 million |

| Forecasted market size in 2030 | US$ 2469.2 million |

| CAGR | 4.2% |

| Base Year | 2024 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Sandvik, Xiamen Tungsten, China Minmetals Corporation, Element Six, Jiangxi Yaosheng, GuangDong XiangLu Tungsten, Chongyi Zhangyyuan Tungsten, Plansee (GTP), JXTC, Japan New Metals, AST (India), Kohsei Co Ltd, ALMT Corp, Kennametal, H.C.Starck, TaeguTec Ltd, Wolfram Company JSC (Russia), Buffalo Tungsten, Eurotungstene, Lineage Alloys |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |