What is Global Portable Ultrasonic Flaw Detectors Market?

The global Portable Ultrasonic Flaw Detectors market is a specialized segment within the broader non-destructive testing (NDT) industry. These devices are used to detect flaws, cracks, and other imperfections in materials without causing any damage. Portable ultrasonic flaw detectors are particularly valued for their ability to provide precise and reliable results in a variety of settings, from industrial plants to field operations. These devices work by emitting high-frequency sound waves into a material and then analyzing the reflected waves to identify any inconsistencies. The market for these detectors is driven by the need for high-quality, reliable inspection methods across various industries, including oil and gas, aerospace, automotive, and manufacturing. As industries continue to prioritize safety and quality, the demand for portable ultrasonic flaw detectors is expected to grow. The market is characterized by technological advancements, with newer models offering enhanced features such as digital displays, data storage, and improved accuracy.

Touch Screen, Key in the Global Portable Ultrasonic Flaw Detectors Market:

Touch screen and key-based interfaces are two primary types of user interfaces found in portable ultrasonic flaw detectors. Touch screen interfaces offer a modern, intuitive way to interact with the device. They allow users to easily navigate through menus, adjust settings, and view results with a simple touch. This type of interface is particularly beneficial in environments where quick adjustments and real-time data analysis are crucial. On the other hand, key-based interfaces provide a more traditional method of interaction. These interfaces use physical buttons to control the device, which can be advantageous in harsh environments where touch screens might be less effective due to dirt, oil, or other contaminants. Key-based interfaces are often preferred in industries like mining and oil and gas, where rugged conditions are common. Both types of interfaces have their own set of advantages and are chosen based on the specific needs of the application and the environment in which the device will be used. The choice between touch screen and key-based interfaces often comes down to user preference and the specific requirements of the inspection task. For instance, in the aerospace industry, where precision and accuracy are paramount, a touch screen interface might be preferred for its ease of use and quick access to advanced features. In contrast, in the oil and gas industry, where conditions can be challenging, a key-based interface might be more suitable. Regardless of the type of interface, the primary goal is to provide a reliable, user-friendly way to operate the ultrasonic flaw detector and ensure accurate, consistent results.

Oil and Gas, Mining, Automobile Industry, Machinery Manufacturing, Aerospace, Others in the Global Portable Ultrasonic Flaw Detectors Market:

Portable ultrasonic flaw detectors are widely used across various industries due to their versatility and reliability. In the oil and gas sector, these devices are essential for inspecting pipelines, storage tanks, and other critical infrastructure. They help identify potential issues such as corrosion, cracks, and weld defects, ensuring the integrity and safety of the equipment. In the mining industry, portable ultrasonic flaw detectors are used to inspect mining equipment and structures, helping to prevent failures and extend the lifespan of machinery. The automobile industry also relies on these devices for quality control and safety inspections. They are used to check for flaws in critical components such as engine parts, axles, and chassis, ensuring that vehicles meet safety standards and perform reliably. In machinery manufacturing, portable ultrasonic flaw detectors are used to inspect parts and assemblies during production, helping to maintain high quality and reduce the risk of defects. The aerospace industry uses these devices to inspect aircraft components, including wings, fuselage, and landing gear, ensuring that they are free from defects and capable of withstanding the stresses of flight. Other industries, such as construction and power generation, also use portable ultrasonic flaw detectors for various inspection tasks. These devices are valued for their ability to provide accurate, non-destructive testing, helping to ensure the safety and reliability of critical infrastructure and equipment.

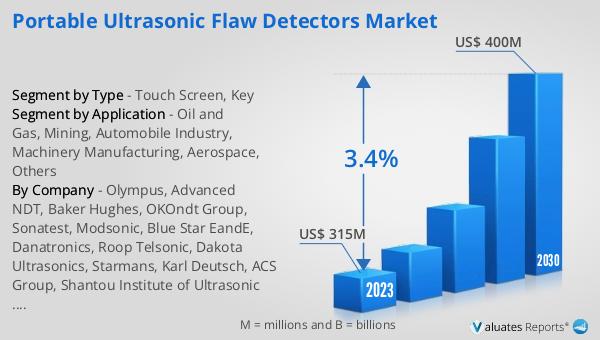

Global Portable Ultrasonic Flaw Detectors Market Outlook:

The global Portable Ultrasonic Flaw Detectors market was valued at US$ 315 million in 2023 and is anticipated to reach US$ 400 million by 2030, witnessing a CAGR of 3.4% during the forecast period from 2024 to 2030. The market is dominated by a few key players, with the top five manufacturers accounting for over 54% of the global market share. Applications of portable ultrasonic flaw detectors are fairly evenly distributed across various industries, including energy, aerospace, oil and gas, and automotive, each contributing approximately 15% to the overall market. This widespread application underscores the versatility and importance of these devices in ensuring the safety and reliability of critical infrastructure and equipment across different sectors. The steady growth of the market reflects the ongoing demand for high-quality, non-destructive testing solutions that can provide accurate and reliable results in a variety of settings. As industries continue to prioritize safety and quality, the demand for portable ultrasonic flaw detectors is expected to remain strong.

| Report Metric | Details |

| Report Name | Portable Ultrasonic Flaw Detectors Market |

| Accounted market size in 2023 | US$ 315 million |

| Forecasted market size in 2030 | US$ 400 million |

| CAGR | 3.4% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Olympus, Advanced NDT, Baker Hughes, OKOndt Group, Sonatest, Modsonic, Blue Star EandE, Danatronics, Roop Telsonic, Dakota Ultrasonics, Starmans, Karl Deutsch, ACS Group, Shantou Institute of Ultrasonic Instruments Co., Ltd., Huatec Group, Wuhan Zhongke Innovation Technology Co., Ltd., Nantong Union Digital Technology Development Co. Ltd., Guangzhou Doppler Electronic Technologies Incorporated Company |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |