What is Global Pneumatic Drum Pumps Market?

The Global Pneumatic Drum Pumps Market refers to the worldwide industry focused on the production and distribution of pneumatic drum pumps. These pumps are essential tools used to transfer liquids from drums or barrels efficiently and safely. They operate using compressed air, which makes them highly reliable and suitable for handling various types of fluids, including corrosive and viscous substances. The market encompasses a wide range of industries, including chemical, pharmaceutical, food processing, and environmental protection, where the need for safe and efficient liquid transfer is paramount. The growth of this market is driven by the increasing demand for automation and safety in industrial processes, as well as the need for efficient handling of hazardous materials. The market is characterized by a diverse range of products, including plastic and metal drum pumps, each designed to meet specific industry requirements. As industries continue to evolve and prioritize safety and efficiency, the demand for pneumatic drum pumps is expected to grow, making this market a critical component of modern industrial operations.

Plastic Drum Pumps, Metal Drum Pumps in the Global Pneumatic Drum Pumps Market:

Plastic drum pumps and metal drum pumps are two primary categories within the Global Pneumatic Drum Pumps Market, each offering unique advantages and applications. Plastic drum pumps are typically made from materials like polypropylene, PVC, or polyethylene, which provide excellent resistance to corrosive chemicals and are lightweight, making them easy to handle. These pumps are ideal for industries that deal with aggressive chemicals, such as the chemical and pharmaceutical sectors, where the risk of corrosion is high. Plastic drum pumps are also cost-effective, making them a popular choice for businesses looking to balance performance and budget. On the other hand, metal drum pumps are constructed from robust materials like stainless steel, aluminum, or brass, offering superior durability and strength. These pumps are well-suited for heavy-duty applications and can handle a wide range of fluids, including oils, solvents, and other industrial liquids. Metal drum pumps are often used in industries where the transfer of high-viscosity fluids or abrasive substances is required, such as in the food processing and environmental protection sectors. The choice between plastic and metal drum pumps depends on various factors, including the type of fluid being transferred, the operating environment, and the specific requirements of the application. Both types of pumps are designed to ensure safe and efficient fluid transfer, minimizing the risk of spills and contamination. As the Global Pneumatic Drum Pumps Market continues to grow, manufacturers are focusing on innovation and product development to meet the evolving needs of different industries. This includes the development of pumps with enhanced features, such as improved flow rates, ergonomic designs, and compatibility with a wider range of fluids. Additionally, there is a growing emphasis on sustainability, with manufacturers exploring eco-friendly materials and energy-efficient technologies to reduce the environmental impact of their products. Overall, plastic and metal drum pumps play a crucial role in the Global Pneumatic Drum Pumps Market, providing reliable solutions for a diverse range of industrial applications.

Chemical Industry, Environmental Potection Industry, Pharmaceutical Industry, Food Processing Industry, Others in the Global Pneumatic Drum Pumps Market:

The Global Pneumatic Drum Pumps Market finds extensive usage across various industries, including the chemical industry, environmental protection industry, pharmaceutical industry, food processing industry, and others. In the chemical industry, pneumatic drum pumps are essential for the safe and efficient transfer of hazardous chemicals, solvents, and acids. These pumps help prevent spills and leaks, ensuring the safety of workers and the environment. The ability to handle corrosive substances makes them indispensable in chemical manufacturing and processing plants. In the environmental protection industry, pneumatic drum pumps are used for the transfer of waste liquids, treatment chemicals, and other fluids involved in pollution control and waste management processes. They play a critical role in ensuring that hazardous materials are handled safely and disposed of properly, minimizing the risk of environmental contamination. The pharmaceutical industry relies on pneumatic drum pumps for the precise and hygienic transfer of liquid ingredients, solvents, and cleaning agents. These pumps help maintain the integrity of pharmaceutical products by preventing contamination and ensuring accurate dosing. The food processing industry uses pneumatic drum pumps to transfer various food-grade liquids, such as oils, syrups, and flavorings. These pumps are designed to meet strict hygiene standards, ensuring that food products remain safe and free from contamination. Additionally, pneumatic drum pumps are used in other industries, such as automotive, cosmetics, and agriculture, where the efficient and safe transfer of liquids is essential. The versatility and reliability of pneumatic drum pumps make them a valuable asset in any industry that requires the handling of liquids. As industries continue to prioritize safety, efficiency, and environmental sustainability, the demand for pneumatic drum pumps is expected to grow, further driving the expansion of the Global Pneumatic Drum Pumps Market.

Global Pneumatic Drum Pumps Market Outlook:

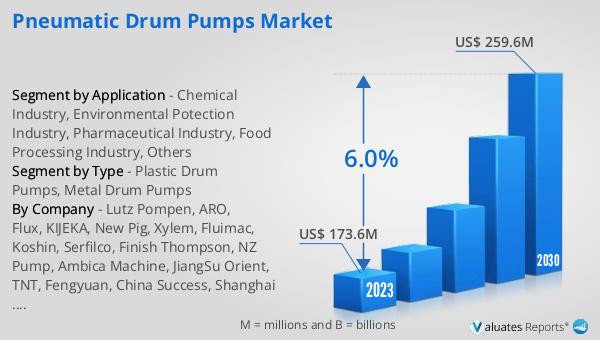

The global Pneumatic Drum Pumps market was valued at US$ 173.6 million in 2023 and is anticipated to reach US$ 259.6 million by 2030, witnessing a CAGR of 6.0% during the forecast period 2024-2030. This growth reflects the increasing demand for efficient and safe liquid transfer solutions across various industries. The market's expansion is driven by factors such as the rising need for automation in industrial processes, stringent safety regulations, and the growing emphasis on environmental sustainability. As industries continue to evolve and adopt advanced technologies, the demand for pneumatic drum pumps is expected to rise, contributing to the market's robust growth. The market outlook indicates a positive trajectory, with manufacturers focusing on innovation and product development to meet the diverse needs of different industries. This includes the introduction of pumps with enhanced features, such as improved flow rates, ergonomic designs, and compatibility with a wider range of fluids. Additionally, there is a growing emphasis on sustainability, with manufacturers exploring eco-friendly materials and energy-efficient technologies to reduce the environmental impact of their products. Overall, the Global Pneumatic Drum Pumps Market is poised for significant growth, driven by the increasing demand for reliable and efficient liquid transfer solutions across various industries.

| Report Metric | Details |

| Report Name | Pneumatic Drum Pumps Market |

| Accounted market size in 2023 | US$ 173.6 million |

| Forecasted market size in 2030 | US$ 259.6 million |

| CAGR | 6.0% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Lutz Pompen, ARO, Flux, KIJEKA, New Pig, Xylem, Fluimac, Koshin, Serfilco, Finish Thompson, NZ Pump, Ambica Machine, JiangSu Orient, TNT, Fengyuan, China Success, Shanghai Yangguang, Shanghai Shangwo |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |