What is Global PET Sheet Extrusion Line Market?

The Global PET Sheet Extrusion Line Market refers to the industry focused on the production and sale of machinery used to manufacture PET (Polyethylene Terephthalate) sheets through the extrusion process. PET sheets are widely used in various industries due to their excellent properties such as high strength, clarity, and recyclability. The extrusion line is a series of machines that melt PET pellets and form them into continuous sheets of varying thicknesses. These sheets are then used in packaging, automotive, construction, and other applications. The market for PET sheet extrusion lines is driven by the growing demand for sustainable and recyclable packaging solutions, advancements in extrusion technology, and the increasing use of PET sheets in diverse end-use industries. The market is characterized by the presence of several key players who offer a range of extrusion lines with different capacities and features to cater to the specific needs of their customers.

Multilayer, Single Layer in the Global PET Sheet Extrusion Line Market:

In the Global PET Sheet Extrusion Line Market, there are two primary types of extrusion lines: multilayer and single layer. Multilayer extrusion lines are designed to produce PET sheets with multiple layers, each serving a specific function. These layers can include barrier layers to protect against moisture and oxygen, adhesive layers to bond different materials, and structural layers to provide strength and rigidity. Multilayer PET sheets are commonly used in packaging applications where enhanced performance characteristics are required, such as in food and beverage packaging to extend shelf life and maintain product freshness. The multilayer extrusion process involves the simultaneous extrusion of multiple polymer streams, which are then combined to form a single sheet with distinct layers. This process requires advanced machinery and precise control to ensure uniform layer distribution and adhesion. On the other hand, single layer extrusion lines produce PET sheets with a uniform composition throughout. These sheets are simpler to manufacture and are typically used in applications where the additional properties provided by multilayer sheets are not necessary. Single layer PET sheets are commonly used in thermoforming applications, where they are heated and molded into various shapes for packaging, automotive parts, and other products. The single layer extrusion process involves melting PET pellets and extruding them through a die to form a continuous sheet. This process is relatively straightforward and cost-effective, making it suitable for high-volume production. Both multilayer and single layer PET sheet extrusion lines have their advantages and are chosen based on the specific requirements of the end-use application. Multilayer extrusion lines offer greater versatility and the ability to tailor the properties of the PET sheet to meet specific needs, while single layer extrusion lines provide a more economical solution for applications where additional layers are not required. The choice between multilayer and single layer extrusion lines depends on factors such as the desired properties of the final product, production volume, and cost considerations. In summary, the Global PET Sheet Extrusion Line Market encompasses both multilayer and single layer extrusion lines, each serving different needs and applications. Multilayer extrusion lines are used to produce PET sheets with multiple layers, offering enhanced performance characteristics for demanding applications such as food and beverage packaging. Single layer extrusion lines produce uniform PET sheets that are suitable for a wide range of applications, including thermoforming and general packaging. The choice between multilayer and single layer extrusion lines depends on the specific requirements of the end-use application, with each type offering distinct advantages in terms of performance, cost, and production efficiency.

Food & Beverage, Personal Care & Cosmetics, Pharmaceutical, Electrical and Electronics, Other in the Global PET Sheet Extrusion Line Market:

The Global PET Sheet Extrusion Line Market finds extensive usage across various industries, including Food & Beverage, Personal Care & Cosmetics, Pharmaceutical, Electrical and Electronics, and others. In the Food & Beverage industry, PET sheets are widely used for packaging applications due to their excellent barrier properties, clarity, and recyclability. They are used to manufacture containers, trays, and lids that help preserve the freshness and quality of food products. The ability of PET sheets to provide a strong barrier against moisture and oxygen makes them ideal for packaging perishable items such as dairy products, meats, and ready-to-eat meals. Additionally, PET sheets are used in the production of beverage bottles, offering a lightweight and durable packaging solution that is also easy to recycle. In the Personal Care & Cosmetics industry, PET sheets are used for packaging a wide range of products, including shampoos, lotions, creams, and other personal care items. The clarity and aesthetic appeal of PET sheets make them an attractive choice for packaging products that need to stand out on retail shelves. Moreover, PET sheets provide excellent protection against external contaminants, ensuring that the products remain safe and effective throughout their shelf life. The versatility of PET sheets allows for the creation of various packaging designs, including bottles, jars, and blister packs, catering to the diverse needs of the personal care and cosmetics industry. The Pharmaceutical industry also relies on PET sheets for packaging applications. PET sheets are used to manufacture blister packs, which are commonly used for packaging tablets, capsules, and other solid dosage forms. The barrier properties of PET sheets help protect pharmaceutical products from moisture, light, and oxygen, ensuring their stability and efficacy. Additionally, PET sheets are used in the production of medical device packaging, providing a sterile and secure environment for sensitive medical products. The recyclability of PET sheets aligns with the growing emphasis on sustainability in the pharmaceutical industry, making them a preferred choice for eco-friendly packaging solutions. In the Electrical and Electronics industry, PET sheets are used for various applications, including the production of protective films, insulators, and components for electronic devices. The excellent electrical insulation properties of PET sheets make them suitable for use in electronic components, where they help prevent short circuits and protect sensitive electronic parts. Additionally, PET sheets are used in the production of display screens, providing a clear and durable protective layer that enhances the performance and longevity of electronic devices. The versatility and durability of PET sheets make them an essential material in the manufacturing of a wide range of electrical and electronic products. Apart from the aforementioned industries, PET sheets are also used in other applications, including automotive, construction, and industrial sectors. In the automotive industry, PET sheets are used for interior and exterior components, offering a lightweight and durable solution that helps improve fuel efficiency and reduce emissions. In the construction industry, PET sheets are used for glazing, roofing, and insulation applications, providing a strong and weather-resistant material that enhances the performance and longevity of buildings. In the industrial sector, PET sheets are used for various applications, including machinery components, protective covers, and packaging materials, offering a versatile and reliable solution for a wide range of industrial needs. In conclusion, the Global PET Sheet Extrusion Line Market serves a diverse range of industries, including Food & Beverage, Personal Care & Cosmetics, Pharmaceutical, Electrical and Electronics, and others. The excellent properties of PET sheets, such as clarity, strength, barrier protection, and recyclability, make them a preferred choice for various packaging and manufacturing applications. The versatility and adaptability of PET sheets allow them to meet the specific needs of different industries, providing a reliable and sustainable solution for a wide range of products and applications.

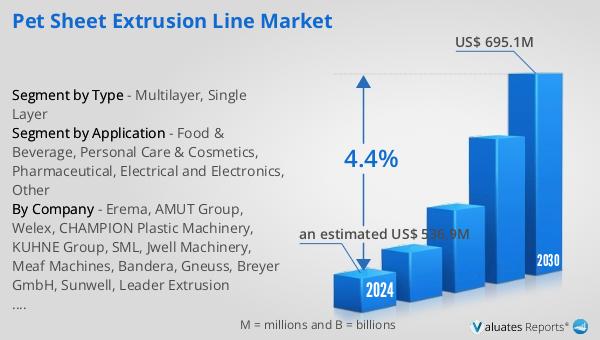

Global PET Sheet Extrusion Line Market Outlook:

The global PET Sheet Extrusion Line market is anticipated to grow from an estimated value of US$ 536.9 million in 2024 to reach US$ 695.1 million by 2030, reflecting a compound annual growth rate (CAGR) of 4.4% during the forecast period from 2024 to 2030. This growth is driven by the increasing demand for PET sheets across various industries due to their excellent properties and the rising focus on sustainable and recyclable packaging solutions. The market is characterized by the presence of several key players who dominate the industry, with the top five manufacturers being Erema, AMUT Group, Welex, CHAMPION Plastic, and KUHNE Group. These companies collectively hold more than 30% of the market share, indicating their significant influence and competitive positioning in the market. The leading manufacturers are continuously investing in research and development to enhance their product offerings and meet the evolving needs of their customers. They are also focusing on expanding their production capacities and strengthening their distribution networks to cater to the growing demand for PET sheet extrusion lines globally. The competitive landscape of the market is marked by strategic collaborations, mergers and acquisitions, and technological advancements aimed at gaining a competitive edge and expanding market presence.

| Report Metric | Details |

| Report Name | PET Sheet Extrusion Line Market |

| Accounted market size in 2024 | an estimated US$ 536.9 million |

| Forecasted market size in 2030 | US$ 695.1 million |

| CAGR | 4.4% |

| Base Year | 2024 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Erema, AMUT Group, Welex, CHAMPION Plastic Machinery, KUHNE Group, SML, Jwell Machinery, Meaf Machines, Bandera, Gneuss, Breyer GmbH, Sunwell, Leader Extrusion Machinery, USEON |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |