What is Global Ophthalmic Lens Coating Equipment Market?

The Global Ophthalmic Lens Coating Equipment Market refers to the industry that manufactures and supplies machines used to apply various coatings to ophthalmic lenses. These coatings can include anti-reflective (AR) coatings, scratch-resistant coatings, and mirror coatings, among others. The equipment used in this market is essential for enhancing the performance and durability of lenses used in eyeglasses, contact lenses, and other optical devices. The market is driven by the increasing demand for high-quality vision correction products, advancements in coating technologies, and the growing awareness of eye health. Additionally, the rise in the aging population and the prevalence of vision-related issues contribute to the market's growth. Companies in this market focus on innovation and efficiency to meet the diverse needs of consumers and healthcare providers.

Dip Coating, Spin Coating, Others in the Global Ophthalmic Lens Coating Equipment Market:

Dip coating, spin coating, and other methods are integral to the Global Ophthalmic Lens Coating Equipment Market. Dip coating involves immersing the lens into a coating solution and then withdrawing it at a controlled speed to achieve a uniform layer. This method is widely used for applying hard coatings that enhance the scratch resistance of lenses. The process is relatively simple and cost-effective, making it suitable for large-scale production. Spin coating, on the other hand, involves placing the lens on a rotating platform and dispensing the coating solution onto the center. The centrifugal force spreads the solution evenly across the lens surface, resulting in a thin and uniform coating. Spin coating is particularly effective for applying anti-reflective (AR) coatings, which improve the clarity and visual comfort of lenses by reducing glare. Other methods in the market include vacuum deposition and spray coating. Vacuum deposition involves placing the lens in a vacuum chamber and depositing the coating material onto the lens surface through physical or chemical vapor deposition. This method is highly precise and is used for applying advanced coatings such as mirror coatings and multi-layer AR coatings. Spray coating, as the name suggests, involves spraying the coating solution onto the lens surface using a nozzle. This method is versatile and can be used for various types of coatings, including hydrophobic and oleophobic coatings that repel water and oil, respectively. Each of these methods has its advantages and limitations, and the choice of method depends on factors such as the type of coating, the desired thickness, and the production volume. The advancements in these coating techniques have significantly improved the quality and performance of ophthalmic lenses, making them more durable, comfortable, and visually appealing.

Hard Coating, AR Coating, Mirror Coating, Others in the Global Ophthalmic Lens Coating Equipment Market:

The usage of Global Ophthalmic Lens Coating Equipment Market spans various areas, including hard coating, AR coating, mirror coating, and others. Hard coating is one of the most common applications, providing a protective layer that enhances the scratch resistance of lenses. This coating is essential for maintaining the clarity and longevity of lenses, especially for those used in everyday eyeglasses. The hard coating process typically involves dip coating or spin coating methods, which ensure a uniform and durable layer. AR coating, or anti-reflective coating, is another critical application. This coating reduces glare and reflections on the lens surface, improving visual comfort and clarity. AR coatings are particularly beneficial for people who spend a lot of time in front of screens or under bright lighting conditions. The application of AR coatings often involves spin coating or vacuum deposition methods, which provide a thin and even layer that enhances the optical performance of the lens. Mirror coating is used to create reflective surfaces on lenses, often for aesthetic purposes or to reduce light transmission in sunglasses. This coating is applied using vacuum deposition techniques, which allow for precise control over the thickness and uniformity of the reflective layer. Other applications of lens coating equipment include hydrophobic and oleophobic coatings, which repel water and oil, respectively. These coatings are applied using spray coating methods and are particularly useful for lenses used in harsh environments or for sports activities. Additionally, some lenses may require multi-layer coatings that combine different properties, such as scratch resistance, anti-reflective, and hydrophobic features. The advancements in coating technologies have enabled the development of such multi-functional coatings, providing comprehensive protection and performance enhancements for ophthalmic lenses. The versatility and efficiency of modern lens coating equipment have made it possible to meet the diverse needs of consumers, from everyday eyeglasses to specialized optical devices.

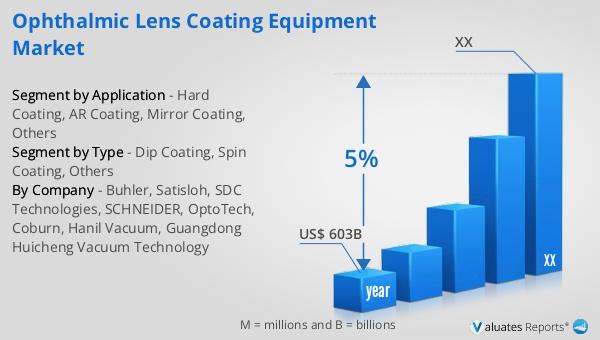

Global Ophthalmic Lens Coating Equipment Market Outlook:

According to our research, the global market for medical devices is projected to reach approximately $603 billion by the year 2023, with an anticipated growth rate of 5% annually over the next six years. This substantial market size underscores the critical role that medical devices play in healthcare, ranging from diagnostic tools to therapeutic equipment. The steady growth rate reflects ongoing advancements in medical technology, increasing healthcare expenditures, and the rising prevalence of chronic diseases that necessitate sophisticated medical interventions. As the demand for innovative and effective medical devices continues to rise, companies in this sector are focusing on research and development to introduce cutting-edge solutions that improve patient outcomes and streamline healthcare processes. The market's expansion is also driven by the growing adoption of digital health technologies, such as telemedicine and wearable devices, which are transforming the way healthcare services are delivered. Additionally, the aging global population is contributing to the increased demand for medical devices, as older individuals typically require more medical care and monitoring. Overall, the projected growth of the medical device market highlights the dynamic nature of the healthcare industry and the continuous efforts to enhance the quality and accessibility of medical care worldwide.

| Report Metric | Details |

| Report Name | Ophthalmic Lens Coating Equipment Market |

| Accounted market size in year | US$ 603 billion |

| CAGR | 5% |

| Base Year | year |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Buhler, Satisloh, SDC Technologies, SCHNEIDER, OptoTech, Coburn, Hanil Vacuum, Guangdong Huicheng Vacuum Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |