What is Global Meta-aramid Honeycomb Cores Market?

The Global Meta-aramid Honeycomb Cores Market is a specialized segment within the broader materials market, focusing on the production and distribution of honeycomb cores made from meta-aramid fibers. These honeycomb cores are known for their exceptional strength-to-weight ratio, thermal stability, and resistance to chemicals and flames. Meta-aramid fibers, such as those branded under names like Nomex, are synthetic fibers in the aramid family that are highly durable and heat-resistant. The honeycomb structure, which mimics the natural hexagonal pattern found in beehives, provides superior mechanical properties while keeping the material lightweight. This makes them ideal for various high-performance applications, particularly in industries where weight savings and material strength are critical. The market for these materials is driven by their increasing use in aerospace, defense, marine, automotive, and other sectors that demand high-performance materials. The global demand for meta-aramid honeycomb cores is expected to grow as industries continue to seek advanced materials that offer both durability and efficiency.

Aerospace Grade, Industrial Grade, Commercial Grade in the Global Meta-aramid Honeycomb Cores Market:

In the Global Meta-aramid Honeycomb Cores Market, products are typically categorized into Aerospace Grade, Industrial Grade, and Commercial Grade, each serving distinct applications and industries. Aerospace Grade meta-aramid honeycomb cores are designed to meet the stringent requirements of the aerospace industry. These cores are used in aircraft interiors, structural components, and other critical areas where weight reduction and high strength are paramount. The aerospace sector demands materials that can withstand extreme temperatures, high stress, and potential exposure to chemicals and flames. Therefore, Aerospace Grade honeycomb cores are engineered to provide maximum performance under these conditions, ensuring safety and efficiency in aircraft operations. Industrial Grade meta-aramid honeycomb cores, on the other hand, are tailored for use in various industrial applications. These include construction, wind energy, and other heavy-duty sectors where durability and strength are essential. Industrial Grade cores are often used in the manufacturing of panels, partitions, and other structural components that require robust performance. They offer a balance between cost and performance, making them suitable for a wide range of industrial uses. Commercial Grade meta-aramid honeycomb cores are designed for less demanding applications compared to their aerospace and industrial counterparts. These cores are used in products such as sporting goods, furniture, and other consumer goods where the primary requirements are lightweight and moderate strength. Commercial Grade cores provide an economical solution for applications that do not require the high-performance characteristics of Aerospace or Industrial Grade materials. Each grade of meta-aramid honeycomb core is engineered to meet specific performance criteria, ensuring that the right material is available for the right application. The versatility of these materials allows them to be used across a broad spectrum of industries, each benefiting from the unique properties of meta-aramid fibers and the honeycomb structure. As technology advances and new applications emerge, the demand for specialized grades of meta-aramid honeycomb cores is expected to grow, further driving innovation and development in this market.

Aerospace, Defense, Marine, Automotive, Others in the Global Meta-aramid Honeycomb Cores Market:

The usage of Global Meta-aramid Honeycomb Cores Market spans several key industries, including Aerospace, Defense, Marine, Automotive, and others. In the Aerospace industry, meta-aramid honeycomb cores are extensively used in the construction of aircraft interiors, such as flooring, partitions, and overhead bins. Their lightweight nature and high strength make them ideal for reducing the overall weight of the aircraft, thereby improving fuel efficiency and performance. Additionally, these materials are used in structural components like wings and fuselage sections, where their ability to withstand high stress and extreme temperatures is crucial. In the Defense sector, meta-aramid honeycomb cores are employed in the manufacturing of military vehicles, protective gear, and other defense-related equipment. Their resistance to flames and chemicals, combined with their lightweight and durable properties, make them suitable for use in harsh and demanding environments. These materials help enhance the performance and safety of military equipment, contributing to the overall effectiveness of defense operations. The Marine industry also benefits from the use of meta-aramid honeycomb cores, particularly in the construction of boat hulls, decks, and bulkheads. The lightweight and corrosion-resistant properties of these materials make them ideal for marine applications, where exposure to water and harsh weather conditions is common. By using meta-aramid honeycomb cores, manufacturers can produce vessels that are both strong and lightweight, improving speed and fuel efficiency. In the Automotive industry, meta-aramid honeycomb cores are used in the production of various components, including body panels, interior parts, and structural reinforcements. The lightweight nature of these materials helps reduce the overall weight of vehicles, leading to improved fuel efficiency and performance. Additionally, their high strength and durability contribute to the safety and longevity of automotive components. Beyond these primary industries, meta-aramid honeycomb cores find applications in other areas such as sporting goods, construction, and consumer electronics. In sporting goods, they are used in the manufacturing of lightweight and durable equipment like helmets, paddles, and protective gear. In construction, these materials are used in the production of panels, partitions, and other structural components that require a balance of strength and weight. In consumer electronics, meta-aramid honeycomb cores are used in the production of lightweight and durable casings for devices such as laptops and smartphones. The versatility and unique properties of meta-aramid honeycomb cores make them a valuable material across a wide range of industries, driving their demand and usage in various applications.

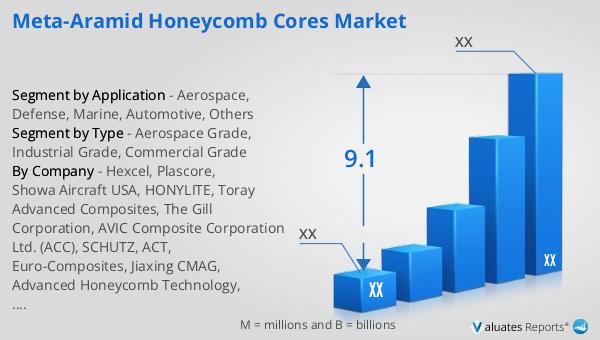

Global Meta-aramid Honeycomb Cores Market Outlook:

According to the survey and statistics of the research team, the global aramid paper market sales reached 480 million yuan in 2022, and it is expected to reach 890 million yuan by 2029, with a compound annual growth rate (CAGR) of 9.1% from 2023 to 2029. North America stands out as the largest production region, accounting for approximately 73% of the market share. Following North America, China and Japan hold 20% and 8% of the market share, respectively. In terms of market size, North America also leads with about 44% of the market share, followed by the Asia Pacific region and Europe, which hold 42% and 14% of the market share, respectively. This data highlights the significant role that North America plays in both the production and consumption of aramid paper, while also indicating substantial contributions from the Asia Pacific and European regions. The projected growth in the market underscores the increasing demand for aramid paper across various industries, driven by its unique properties and wide range of applications.

| Report Metric | Details |

| Report Name | Meta-aramid Honeycomb Cores Market |

| CAGR | 9.1 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Hexcel, Plascore, Showa Aircraft USA, HONYLITE, Toray Advanced Composites, The Gill Corporation, AVIC Composite Corporation Ltd. (ACC), SCHUTZ, ACT, Euro-Composites, Jiaxing CMAG, Advanced Honeycomb Technology, Haxcore, Jiaxing Joybusiness, Regal, TASUNS, Pentapur Composites, ACP Composites |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |