What is Global Medical Grade Engineering Plastics Market?

The Global Medical Grade Engineering Plastics Market refers to the specialized segment of the plastics industry that focuses on producing high-performance plastic materials specifically designed for medical applications. These plastics are engineered to meet stringent regulatory standards and exhibit properties such as biocompatibility, sterilizability, and resistance to chemicals and wear. They are used in a wide range of medical devices and equipment, from surgical instruments to diagnostic machines, and even in implants. The demand for these materials is driven by the growing healthcare sector, advancements in medical technology, and the increasing need for durable, safe, and reliable medical products. As healthcare systems worldwide strive to improve patient outcomes and reduce costs, the role of medical-grade engineering plastics becomes increasingly crucial. These materials not only enhance the performance and longevity of medical devices but also contribute to the overall safety and efficacy of medical treatments. The market for these specialized plastics is expanding as manufacturers continue to innovate and develop new materials that meet the evolving needs of the medical industry.

Medical Grade PP, Medical Grade PEEK, Medical Grade PPSU, Others in the Global Medical Grade Engineering Plastics Market:

Medical Grade PP (Polypropylene), Medical Grade PEEK (Polyether Ether Ketone), Medical Grade PPSU (Polyphenylsulfone), and other specialized plastics play a significant role in the Global Medical Grade Engineering Plastics Market. Medical Grade PP is widely used due to its excellent chemical resistance, low cost, and versatility. It is commonly found in disposable syringes, IV bags, and other single-use medical items. Its ability to withstand sterilization processes makes it a preferred choice for many medical applications. On the other hand, Medical Grade PEEK is known for its exceptional mechanical properties, including high strength, stiffness, and resistance to high temperatures and chemicals. This makes it suitable for more demanding applications such as spinal implants, dental implants, and other long-term implantable devices. PEEK's biocompatibility and ability to be sterilized without degrading its properties further enhance its appeal in the medical field. Medical Grade PPSU is another high-performance plastic known for its toughness, transparency, and resistance to repeated sterilization cycles. It is often used in medical devices that require frequent cleaning and sterilization, such as surgical instruments, sterilization trays, and dental equipment. PPSU's ability to maintain its mechanical properties and clarity after multiple sterilization cycles makes it an ideal material for reusable medical devices. Other specialized medical-grade plastics include materials like Medical Grade PC (Polycarbonate), Medical Grade PEI (Polyetherimide), and Medical Grade TPU (Thermoplastic Polyurethane). These materials offer unique properties that cater to specific medical applications. For instance, Medical Grade PC is known for its impact resistance and optical clarity, making it suitable for use in medical devices like oxygenators, blood filters, and diagnostic equipment. Medical Grade PEI offers high heat resistance and dimensional stability, making it ideal for surgical instruments and other high-temperature applications. Medical Grade TPU is valued for its flexibility, biocompatibility, and resistance to abrasion, making it suitable for catheters, tubing, and other flexible medical devices. The continuous development and innovation in medical-grade engineering plastics are driven by the need to meet the stringent requirements of the medical industry. These materials must not only perform well under various conditions but also comply with regulatory standards to ensure patient safety. As a result, manufacturers invest heavily in research and development to create new materials that offer improved performance, safety, and cost-effectiveness. The growing demand for advanced medical devices and the increasing focus on patient safety and outcomes are expected to drive the growth of the Global Medical Grade Engineering Plastics Market in the coming years.

Implants, Medical Equipment, Others in the Global Medical Grade Engineering Plastics Market:

The usage of Global Medical Grade Engineering Plastics Market in areas such as implants, medical equipment, and other applications is extensive and varied. In the field of implants, medical-grade engineering plastics like PEEK and PPSU are particularly valuable. PEEK, for instance, is used in spinal implants, dental implants, and joint replacements due to its high strength, biocompatibility, and resistance to wear and chemicals. These properties make it an excellent alternative to traditional materials like metals and ceramics, offering benefits such as reduced weight and improved patient comfort. PPSU, with its toughness and resistance to sterilization, is also used in various implantable devices where durability and repeated sterilization are required. In medical equipment, engineering plastics play a crucial role in enhancing the performance, safety, and longevity of devices. Medical Grade PP is commonly used in disposable medical items such as syringes, IV bags, and specimen containers due to its low cost, chemical resistance, and ability to withstand sterilization. Medical Grade PC is used in diagnostic equipment, oxygenators, and blood filters because of its impact resistance and optical clarity. These properties ensure that the equipment can withstand the rigors of medical use while providing accurate and reliable results. Medical Grade PEI is used in surgical instruments and high-temperature applications due to its heat resistance and dimensional stability. The flexibility and biocompatibility of Medical Grade TPU make it ideal for use in catheters, tubing, and other flexible medical devices. Other applications of medical-grade engineering plastics include the production of sterilization trays, dental equipment, and various reusable medical devices. PPSU, for example, is used in sterilization trays and dental equipment due to its ability to withstand repeated sterilization cycles without losing its mechanical properties or clarity. This ensures that the devices remain safe and effective for repeated use. The versatility and performance of medical-grade engineering plastics make them indispensable in the medical field, contributing to the development of safer, more effective, and more durable medical devices and equipment. The continuous innovation and development of new materials in this market are driven by the need to meet the evolving demands of the medical industry, ensuring that healthcare providers have access to the best possible tools and devices to improve patient outcomes.

Global Medical Grade Engineering Plastics Market Outlook:

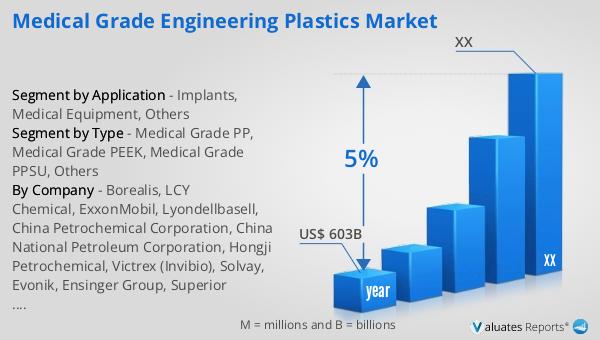

Based on our research, the global market for medical devices is projected to reach approximately US$ 603 billion by the year 2023, with an anticipated growth rate of 5% annually over the next six years. This growth is driven by several factors, including advancements in medical technology, an aging global population, and increasing healthcare expenditures. As medical devices become more sophisticated and integral to patient care, the demand for high-quality, reliable materials such as medical-grade engineering plastics is expected to rise. These materials play a crucial role in the development and manufacturing of medical devices, offering properties such as biocompatibility, durability, and resistance to chemicals and sterilization processes. The expanding market for medical devices underscores the importance of continuous innovation and development in the field of medical-grade engineering plastics, ensuring that healthcare providers have access to the best possible materials to improve patient outcomes and enhance the overall quality of care.

| Report Metric | Details |

| Report Name | Medical Grade Engineering Plastics Market |

| Accounted market size in year | US$ 603 billion |

| CAGR | 5% |

| Base Year | year |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Borealis, LCY Chemical, ExxonMobil, Lyondellbasell, China Petrochemical Corporation, China National Petroleum Corporation, Hongji Petrochemical, Victrex (Invibio), Solvay, Evonik, Ensinger Group, Superior Polymers, ZYPEEK, JHPEEK, Quadrant, Ensigner, China-uju, Changchun JUSEP, Ensinger, Celanese Corporation, Daicel Corporation, DuPont, BASF, Mitsubishi Engineering Plastics |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |