What is Global Insulated Metal Substrate (IMS) Market?

The global Insulated Metal Substrate (IMS) market is a specialized segment within the broader electronics and materials industry. IMS refers to a type of metal substrate that is insulated to provide superior thermal conductivity and electrical insulation. These substrates are primarily used in applications where efficient heat dissipation is crucial, such as in high-power LED lighting, automotive electronics, and industrial control systems. The market for IMS is driven by the increasing demand for high-performance electronic components that can operate reliably under high thermal loads. As industries continue to push the boundaries of electronic performance, the need for materials that can effectively manage heat becomes ever more critical. IMS materials, typically made from aluminum or copper, offer a unique combination of thermal management and electrical insulation, making them ideal for a wide range of applications. The global market for IMS is expected to grow steadily, driven by advancements in technology and increasing adoption across various industries.

Copper Based, Aluminum Based, Others in the Global Insulated Metal Substrate (IMS) Market:

Copper-based, aluminum-based, and other types of IMS materials each have their unique properties and applications within the global market. Copper-based IMS materials are known for their excellent thermal conductivity and electrical performance. Copper, being a highly conductive metal, allows for efficient heat dissipation, which is crucial in high-power applications. These substrates are often used in applications where superior thermal management is required, such as in high-power LED lighting and automotive electronics. The high thermal conductivity of copper ensures that heat is effectively dissipated, preventing overheating and ensuring the longevity and reliability of electronic components. However, copper is also more expensive than aluminum, which can be a limiting factor in its widespread adoption. On the other hand, aluminum-based IMS materials are more commonly used due to their cost-effectiveness and adequate thermal performance. Aluminum offers a good balance between thermal conductivity, electrical insulation, and cost, making it a popular choice for a wide range of applications. Aluminum-based IMS materials are widely used in consumer electronics, automotive electronics, and industrial control systems. The lower cost of aluminum compared to copper makes it an attractive option for manufacturers looking to balance performance and cost. Additionally, aluminum is lightweight, which can be an advantage in applications where weight is a critical factor, such as in automotive and aerospace industries. Other types of IMS materials include those based on different metals or composite materials. These substrates are designed to offer specific properties tailored to particular applications. For example, some IMS materials may use a combination of metals or incorporate ceramic layers to enhance thermal performance or electrical insulation. These specialized substrates are used in niche applications where standard copper or aluminum-based IMS materials may not meet the required performance criteria. The development of new IMS materials is an ongoing area of research, with the aim of improving thermal management, electrical insulation, and overall performance. The choice of IMS material depends on various factors, including the specific application requirements, cost considerations, and performance criteria. Manufacturers must carefully evaluate these factors to select the most appropriate IMS material for their needs. As the demand for high-performance electronic components continues to grow, the development and adoption of advanced IMS materials are expected to increase. This will drive innovation in the IMS market, leading to the introduction of new materials and technologies that offer improved performance and cost-effectiveness. In summary, the global IMS market is characterized by the use of copper-based, aluminum-based, and other specialized materials, each offering unique properties and advantages. Copper-based IMS materials are known for their superior thermal conductivity and electrical performance, making them ideal for high-power applications. Aluminum-based IMS materials offer a good balance between performance and cost, making them widely used in various industries. Other specialized IMS materials are designed to meet specific application requirements, offering tailored properties for niche applications. The ongoing development and adoption of advanced IMS materials are expected to drive growth and innovation in the global IMS market.

Lighting Application, Automotive Industry, Industrial Control, Others in the Global Insulated Metal Substrate (IMS) Market:

The global Insulated Metal Substrate (IMS) market finds extensive usage in various applications, including lighting, automotive, industrial control, and others. In the lighting application, IMS materials are primarily used in high-power LED lighting systems. LEDs generate a significant amount of heat, and efficient thermal management is crucial to ensure their longevity and performance. IMS materials, with their superior thermal conductivity and electrical insulation properties, help dissipate heat effectively, preventing overheating and ensuring the reliability of LED lighting systems. This makes IMS materials an essential component in the design and manufacture of high-power LED lighting solutions, which are widely used in residential, commercial, and industrial settings. In the automotive industry, IMS materials are used in various electronic components and systems, including power modules, motor drives, and lighting systems. The automotive industry demands high-performance materials that can withstand harsh operating conditions, including high temperatures and mechanical stress. IMS materials, particularly those based on aluminum and copper, offer the necessary thermal management and electrical insulation properties required for automotive applications. They help improve the efficiency and reliability of electronic systems, contributing to the overall performance and safety of vehicles. As the automotive industry continues to evolve with the adoption of electric and hybrid vehicles, the demand for advanced IMS materials is expected to increase. In industrial control applications, IMS materials are used in power electronics, motor drives, and control systems. Industrial environments often involve high-power operations and harsh conditions, making efficient thermal management crucial for the reliability and performance of electronic components. IMS materials help dissipate heat effectively, ensuring the longevity and reliability of industrial control systems. They are used in various industrial applications, including automation, robotics, and power distribution systems. The ability of IMS materials to provide superior thermal management and electrical insulation makes them an essential component in the design and manufacture of industrial control systems. Other applications of IMS materials include consumer electronics, telecommunications, and aerospace. In consumer electronics, IMS materials are used in devices that require efficient thermal management, such as smartphones, tablets, and laptops. The increasing demand for high-performance consumer electronics drives the need for advanced IMS materials that can provide effective heat dissipation and electrical insulation. In telecommunications, IMS materials are used in high-power RF and microwave devices, where efficient thermal management is crucial for performance and reliability. In aerospace applications, IMS materials are used in electronic systems that require lightweight and high-performance materials to withstand extreme conditions. In summary, the global IMS market finds extensive usage in various applications, including lighting, automotive, industrial control, and others. In lighting applications, IMS materials are essential for efficient thermal management in high-power LED lighting systems. In the automotive industry, IMS materials are used in electronic components and systems, contributing to the efficiency and reliability of vehicles. In industrial control applications, IMS materials provide superior thermal management and electrical insulation, ensuring the longevity and performance of industrial systems. Other applications of IMS materials include consumer electronics, telecommunications, and aerospace, where efficient thermal management and electrical insulation are crucial for performance and reliability. The diverse applications of IMS materials highlight their importance in various industries and their role in driving innovation and performance in electronic systems.

Global Insulated Metal Substrate (IMS) Market Outlook:

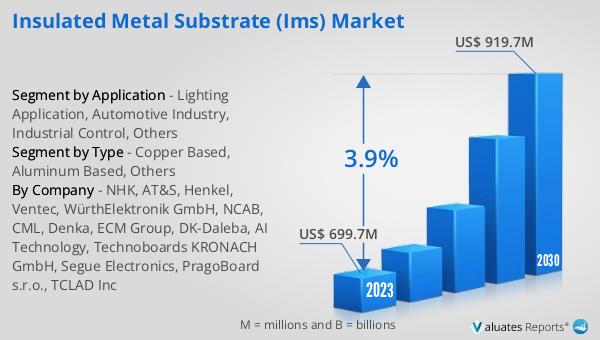

The global Insulated Metal Substrate (IMS) market was valued at approximately USD 699.7 million in 2023 and is projected to reach around USD 919.7 million by 2030, reflecting a compound annual growth rate (CAGR) of 3.9% during the forecast period from 2024 to 2030. The top two players in the market hold a combined share of about 15%. China stands as the largest market, accounting for roughly 25% of the global share, followed by North America and Europe. In terms of product types, aluminum-based IMS materials dominate the market with a share exceeding 50%. When it comes to applications, the industrial control segment is the largest, holding a share of over 36%.

| Report Metric | Details |

| Report Name | Insulated Metal Substrate (IMS) Market |

| Accounted market size in 2023 | US$ 699.7 million |

| Forecasted market size in 2030 | US$ 919.7 million |

| CAGR | 3.9% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | NHK, AT&S, Henkel, Ventec, WürthElektronik GmbH, NCAB, CML, Denka, ECM Group, DK-Daleba, AI Technology, Technoboards KRONACH GmbH, Segue Electronics, PragoBoard s.r.o., TCLAD Inc |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |